An activation process for activated carbon production

A technology of activated carbon production and process, applied in the field of activation technology for activated carbon production, can solve the problems of low utilization rate of resources, low activation efficiency, insufficient activation of activated carbon, etc., and achieve the effect of improving utilization rate, good coherence and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

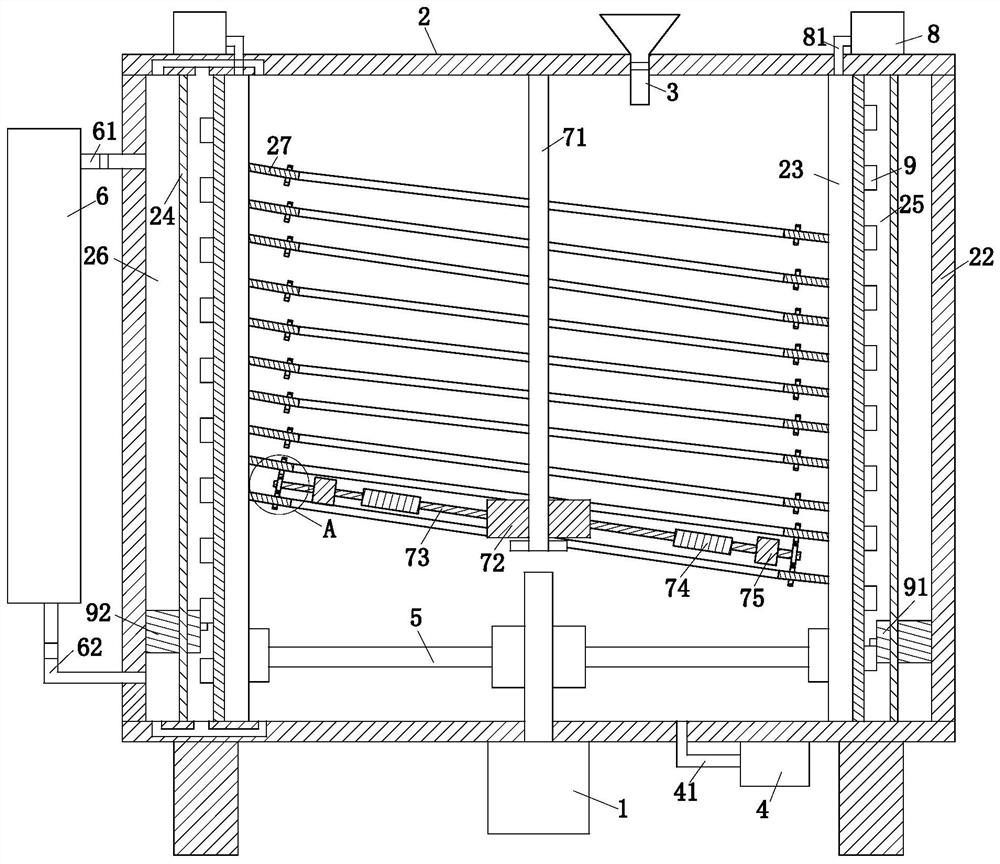

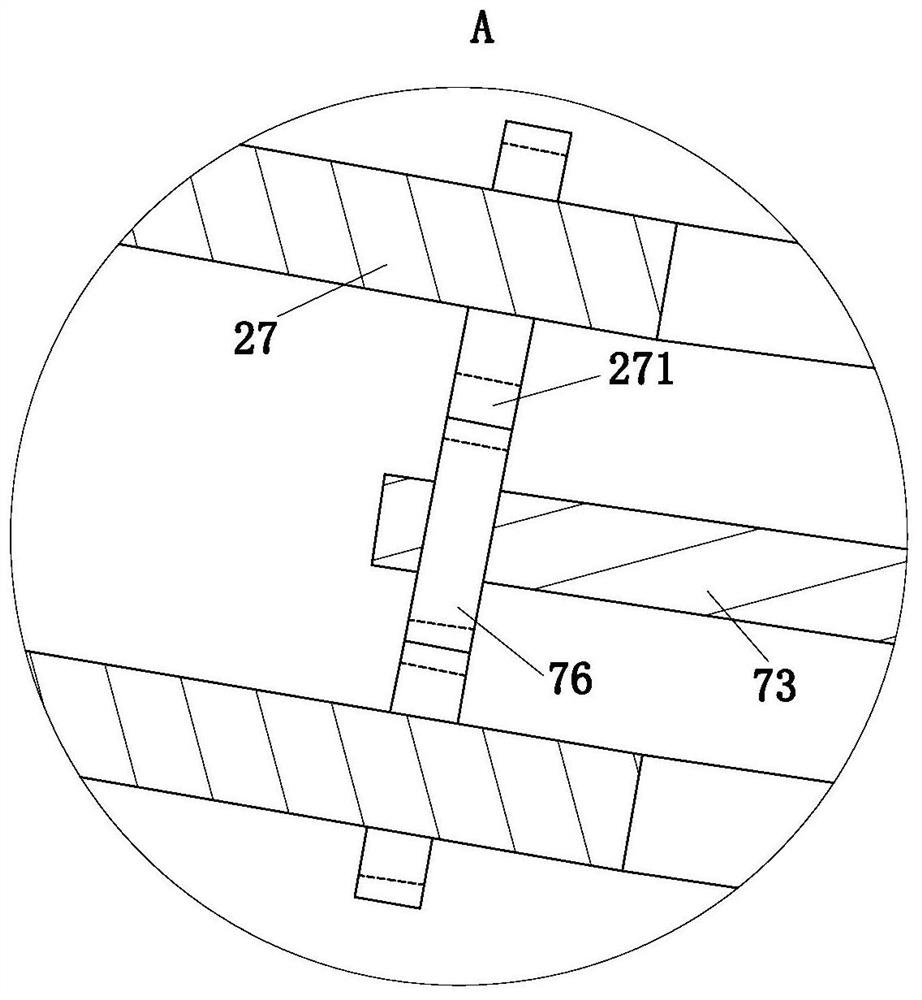

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

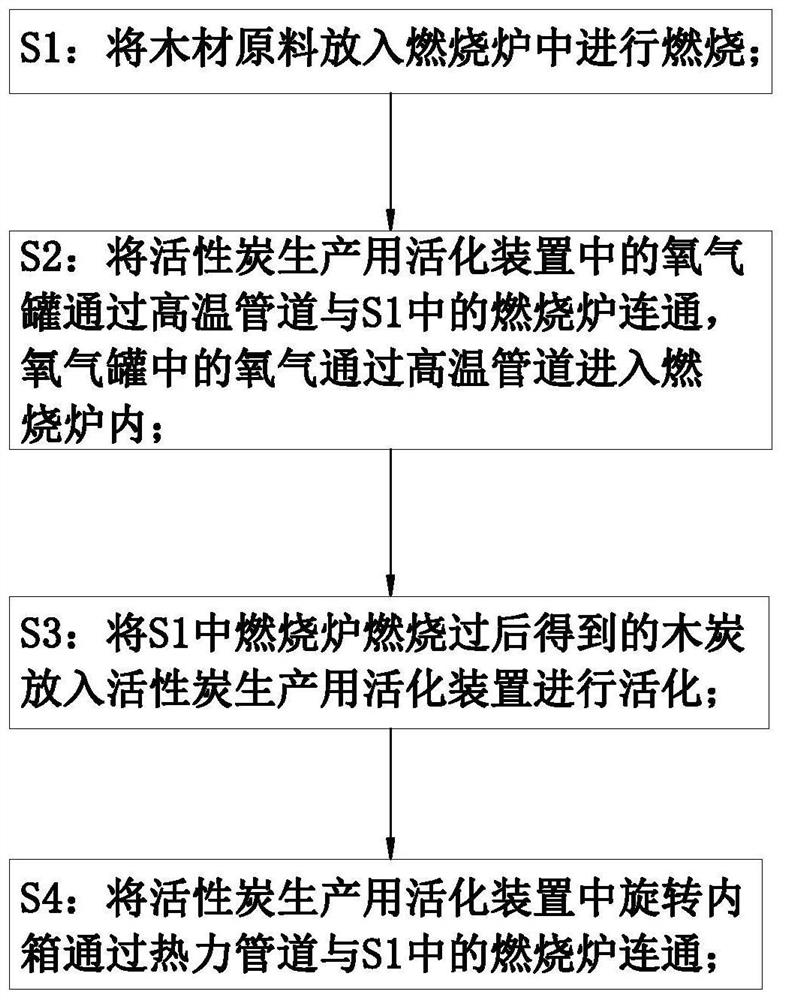

[0029] Such as Figure 1 to Figure 4 Shown, a kind of activated carbon production of the present invention uses activation technique, and this technique comprises the following steps:

[0030] S1: put the wood raw material into the combustion furnace for burning; get charcoal;

[0031] S2: Connect the oxygen tank in the activation device for activated carbon production to the combustion furnace in S1 through a high-temperature pipeline, and the oxygen in the oxygen tank enters the combustion furnace through a high-temperature pipeline; ensure that the wood raw material can be fully burned to obtain high-quality charcoal;

[0032] S3: Put the charcoal obtained after burning in the combustion furnace in S1 into the activation device for activated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com