A rear conveying device for a shearing machine

A conveying device and post-conveying technology, applied in the field of shearing machine auxiliary processing devices, can solve problems such as low conveying efficiency, sheet material accumulation, and increase labor cost and labor intensity, and achieve high conveying efficiency, good stability, and improved conveying stability. Effects of Sexuality and Suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

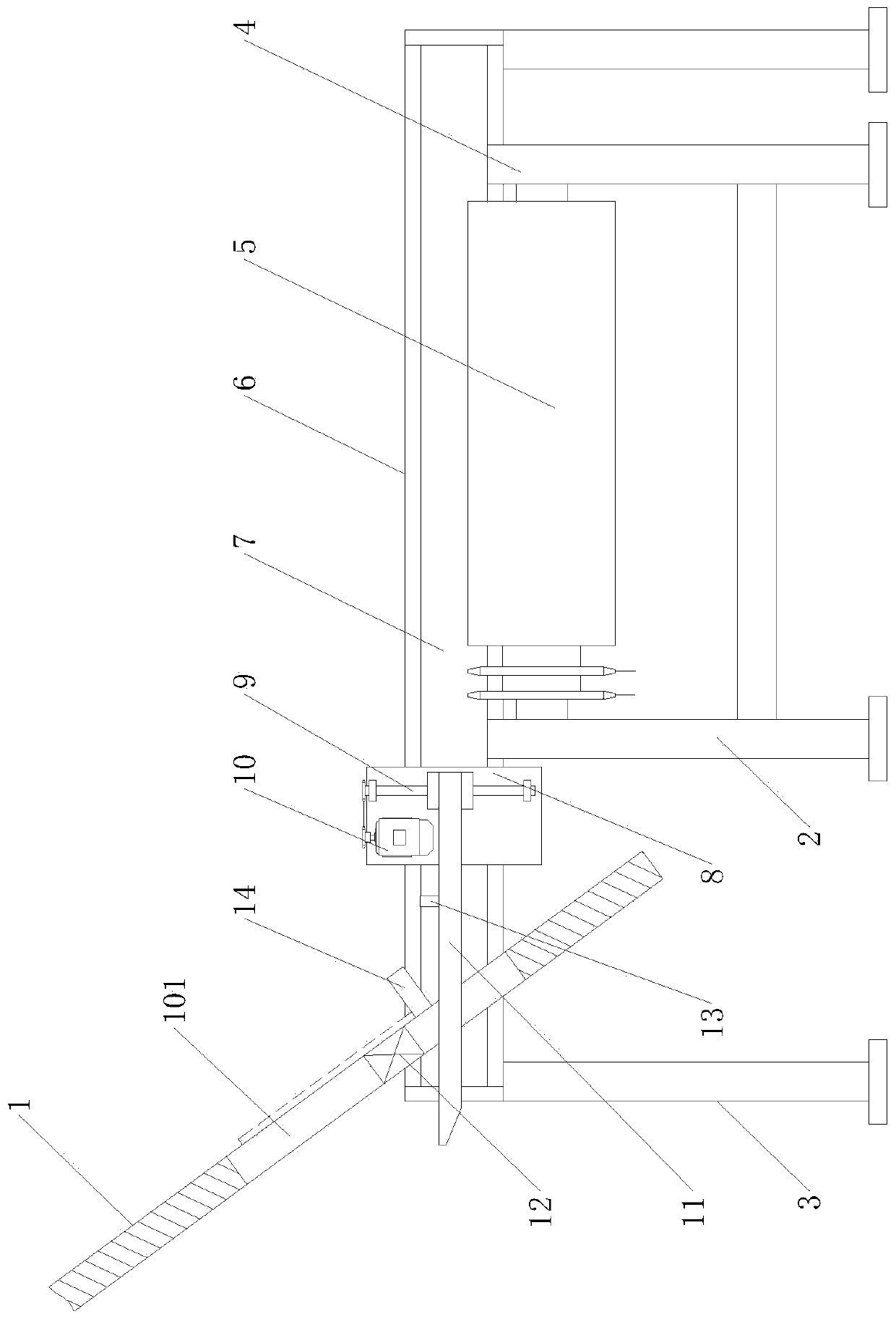

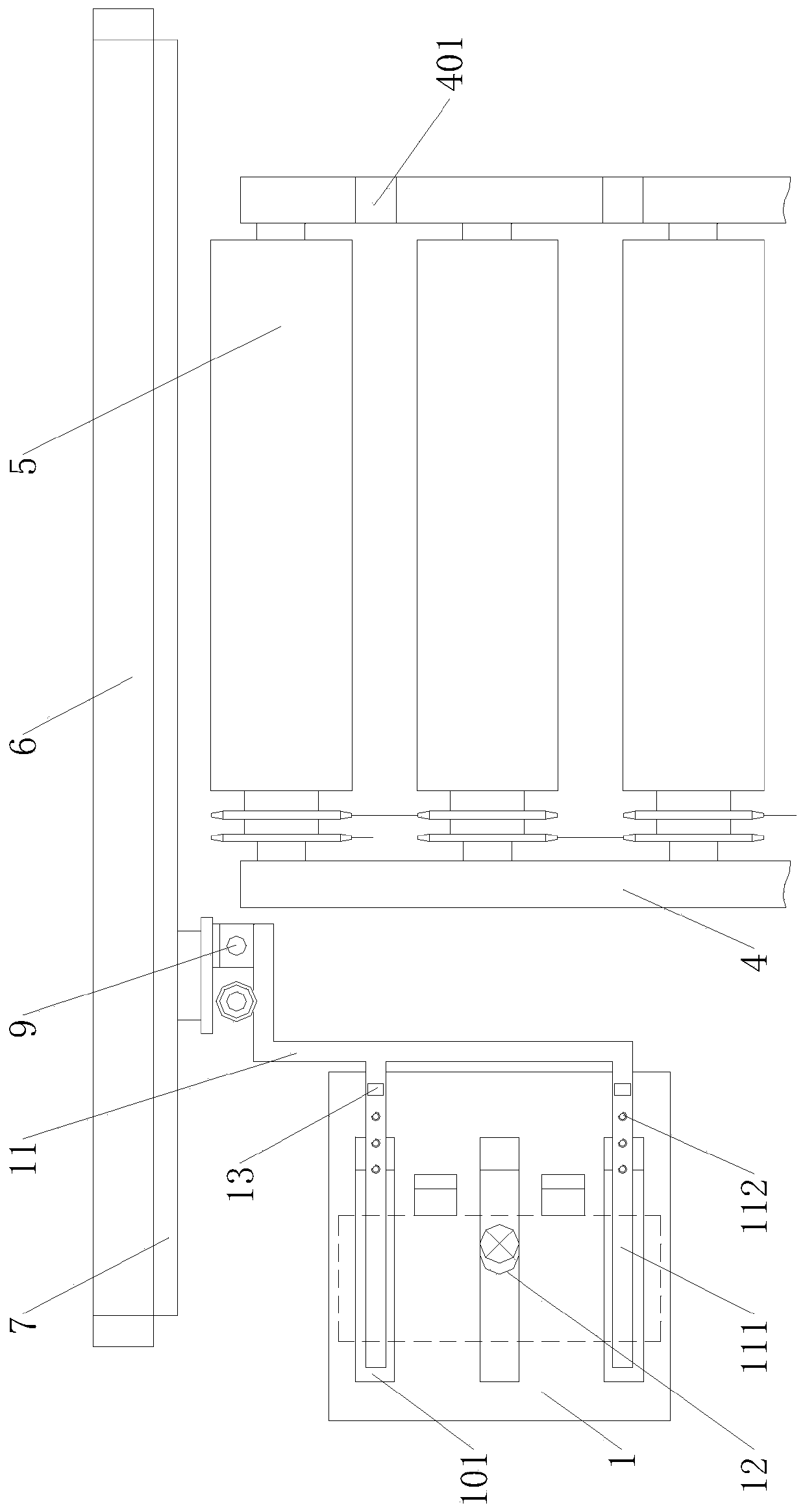

[0015] Example. A kind of conveying device behind the plate shearing machine, constituted as figure 1 As shown, including a slant plate 1, the lower end of the slant plate 1 is provided with a stopper 14, and a plurality of rectangular openings 101 are arranged at intervals on the slant plate 1. 2. The end of the conveying device 2 is provided with a pick-up device 3; the conveying device 2 includes a conveying frame 4, and a number of conveying cylinders 5 are uniformly distributed on the top of the conveying frame 4, and gaps are left between adjacent conveying cylinders 5; The pick-up device 3 includes a base 6 positioned outside the end of the conveyor frame 4, the upper end of the base 6 is connected to a pick-up seat 8 via a pneumatic slide 7, and a vertical ball screw 9 is arranged on the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com