A wire pulling device for power line construction

A wire pulling device and power line technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of insufficient cooperation between the transmission device and the cable, insufficient transmission efficiency, single transmission mechanism, etc., to ensure transmission stability and improve transmission efficiency , Increase the effect of conveying speed and transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

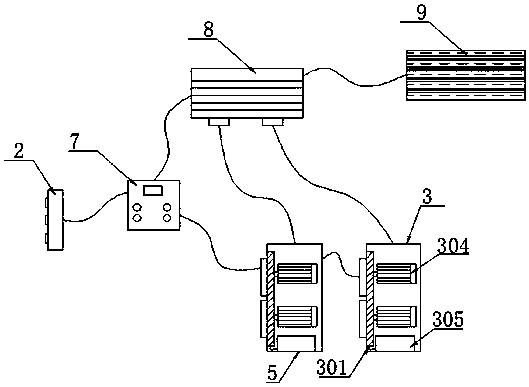

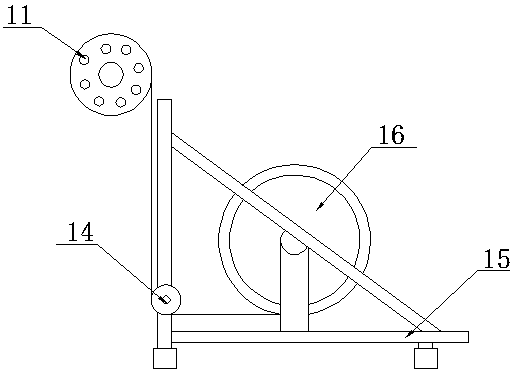

[0028] When the present invention is in use, the trolley 1 is pushed to a designated pulling area and an external power supply is connected, and then the cable on the cable drum 16 passes through the roller 14, the third roller 11, the second roller 10, and the fourth roller 13 Pull out from the first roller 6 at last, then pass auxiliary transmission case 5, main transmission case 3 and just can finish the installation of cable and fix, now main transmission case 3 works, auxiliary transmission case 5 does not work, makes upper transmission wheel 302 and lower The transmission wheel 303 and the cable can be closely matched, and the matching gap remains unchanged, and then the transmission motor 304 is started, so that the upper transmission wheel 302 and the lower transmission wheel 303 rotate and then the cable is pushed forward.

[0029] It is suitable for the case where the pulling power is large and the cable diameter remains unchanged. The auxiliary transmission box can b...

Embodiment 2

[0031] When the present invention is in use, push the trolley 1 to the designated pulling area, then pass the cable on the cable drum 16 through the roller 14, the third roller 11, the second roller 10, and the fourth roller 13 from the first Once the roller 6 is pulled out, the installation and fixation of the cable can be completed through the main transmission box 3, and the pneumatic box 305 and the pneumatic guide rail 301 are controlled by the controller 7, so that the upper transmission wheel 302, the lower transmission wheel 303 and the cable can be closely matched , and then start the transmission motor 304, so that the upper transmission wheel 302 and the lower transmission wheel 303 rotate and then push the cable forward.

[0032] It is suitable for the case where the pulling power is small and the diameter of the cable changes, which greatly improves the flexibility of the device and avoids the waste of energy; it makes the inside of the pulling device closely match...

Embodiment 3

[0033] Embodiment 3: When working outdoors, the solar panel 9 can be turned out to store light energy in the battery 8, and the battery 8 is electrically connected to the hand-held control box 2, the main transmission box 3, the transmission box 5, the controller 7, and the battery 8 Each component provides power for the overall operation of the device.

[0034] It is suitable for places with high light intensity, and some remote mountainous areas do not have an external power supply to provide power when pulling the wire, so the solar panel with it greatly improves the use range of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com