A continuous tunneling system for coal mine roadway

A coal mine roadway, continuous technology, applied in the direction of mine roof support, mining equipment, cutting machinery, etc., can solve the problems of limited working space, inability to continuously excavate, low excavation efficiency, etc., to ensure the effect of conveying stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

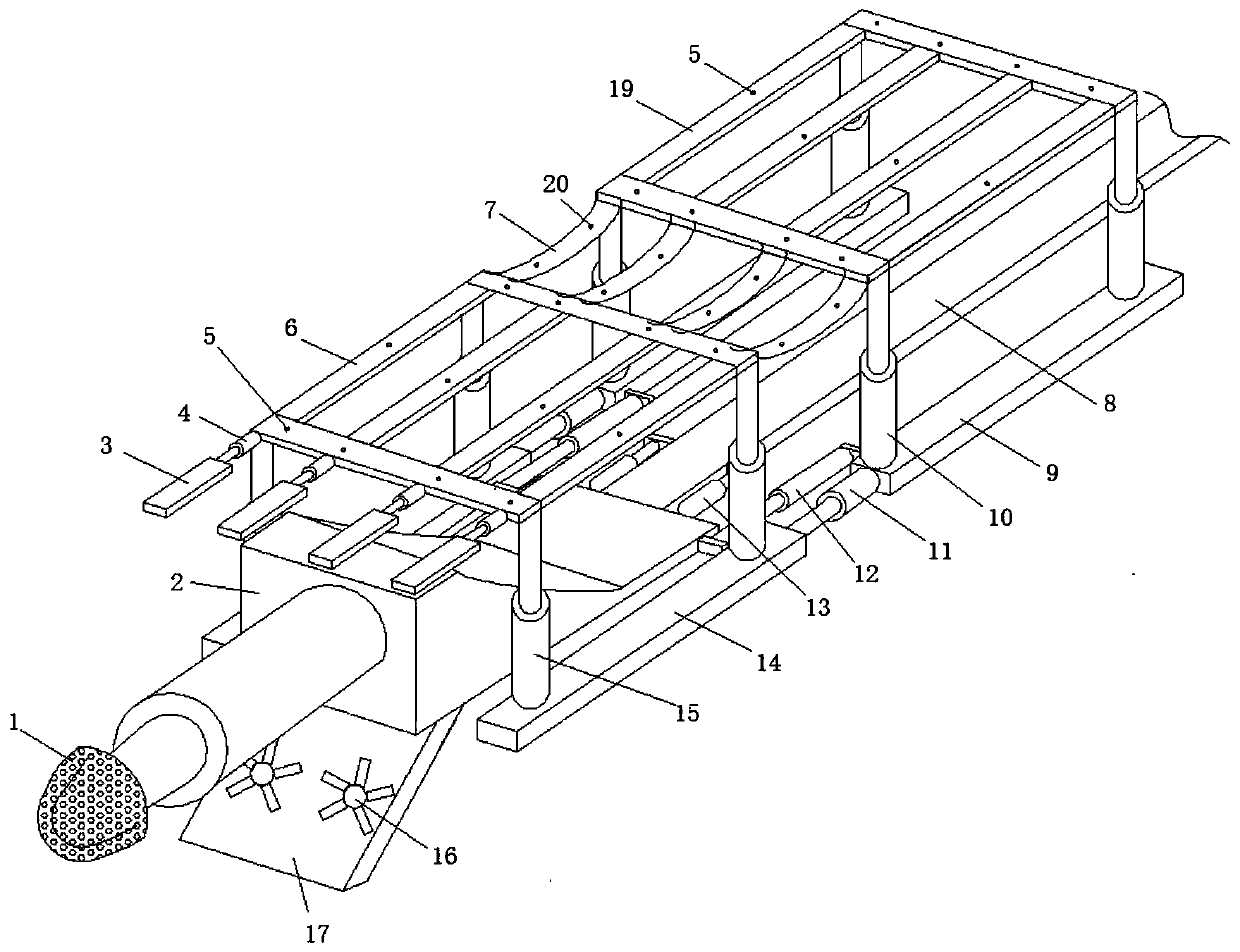

[0024] like figure 1 As shown, a coal mine roadway continuous excavation system, including

[0025] The front frame, the front frame includes a pair of first sliding shoes 14 horizontally arranged side by side and a first support frame 6 above the pair of first sliding shoes 14, and a pair of first sliding shoes 14 passes through two first supporting cylinders 15 respectively. Connected to both sides of the first support frame 6, the front end of the first support frame 6 is horizontally installed with a plurality of telescopic oil cylinders 4, and the telescopic end of each telescopic oil cylinder 4 is horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com