Gear grinding device with vibration feeding mechanism

A gear and grinding technology, which is applied in the direction of grinding feed movement, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of automatic loading and unloading, manual waste, and low efficiency of feeding and processing. High-level problems, to achieve the effect of convenient and fast automatic feeding, saving labor costs, good practical use and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

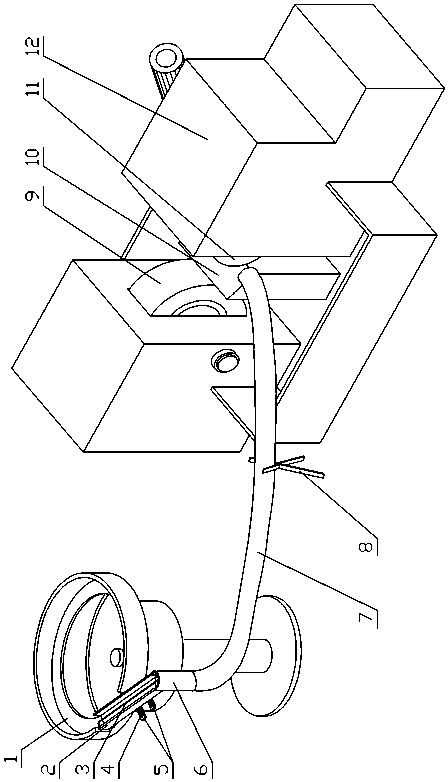

[0010] see figure 1 , figure 2 , the present invention is a gear grinding device with a vibrating feeding mechanism, which has a centerless grinder bed body 12, on which a guide wheel 11, a grinding wheel 9 and a guide plate 10 are arranged, wherein the guide plate is located on the guide Between the grinding wheel and the grinding wheel, an electromagnetic vibration feeding mechanism 1 is provided on one side of the centerless grinding machine bed, and two adjustment plates 5 are arranged side by side under the outlet of the electromagnetic vibration feeding mechanism, and an adjustment groove is arranged on the adjustment plate 4. There are gear workpiece guide grooves 2 above the two adjustment plates, and two screw rods 13 are fixed at the bottom of the gear workpiece guide grooves, and the lower parts of the two screw rods are fixed in the corresponding adjustment grooves by nuts 14; the gear workpiece guide grooves There is a workpiece limit rod 3 on the top of the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com