A method for allowing a musical instrument metal piece to have a surface light effect

A technology for metal bodies and musical instruments, which is applied in the field of photochemical surface of metal bodies of musical instruments, which can solve problems such as thickness thinning, musical instrument sound quality and resonance, uneven wall thickness, etc., and achieve the effect of enriching appearance and visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the description of the central idea expressed in the column of the above-mentioned content of the invention, it is expressed in specific embodiments. The embodiments are drawn in proportions and sizes suitable for illustration, rather than in the proportions of actual components. The colors, graphics, and blocks used are all to express the technical ideas of the present invention, and are not intended to limit the present invention.

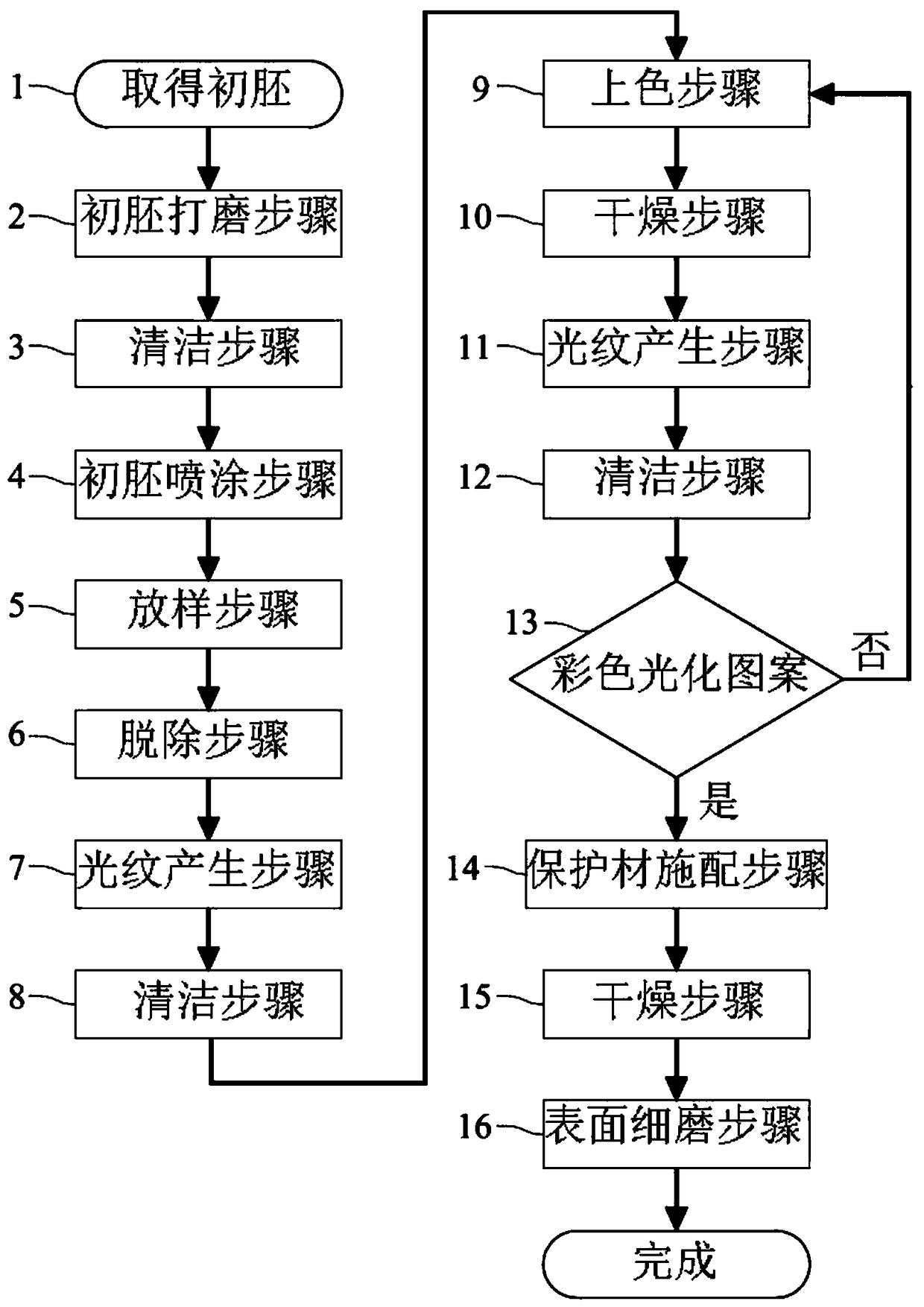

[0034] Such as figure 1 Shown, the method for the actinization of the metal body surface of a kind of musical instrument of the present invention comprises:

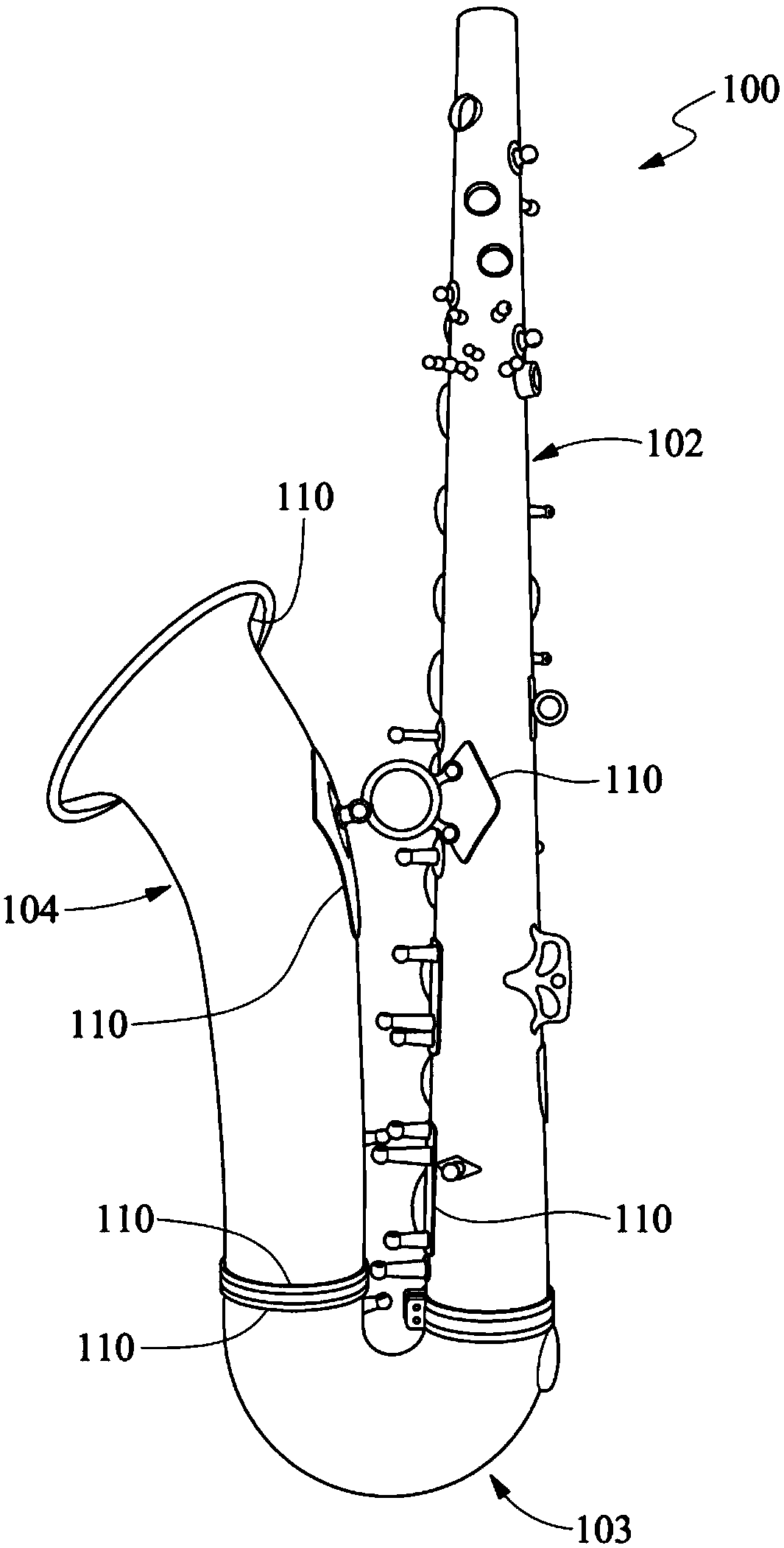

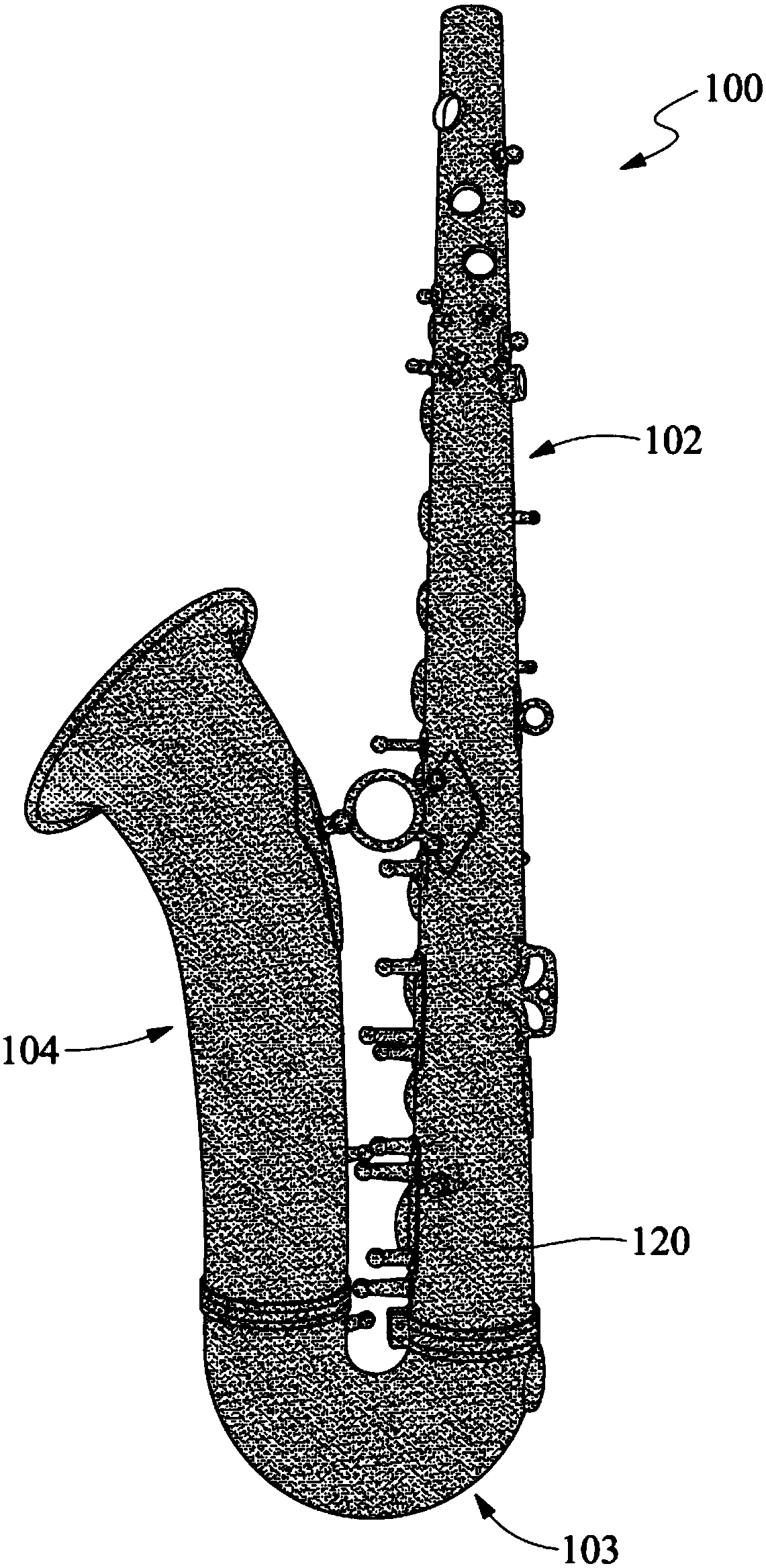

[0035] Step 1, obtain an unpolished and electroplated metal body embryo 100 of a musical instrument; the metal body of the musical instrument includes the pipe body of a wind instrument, the drum shell of a drum instrument, the resonance box panel of a stringed instrument (such as the panel of an electric guitar), Self-sounding instruments (such as cymbals), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com