Novel rolling wheel for pipe bending machine

A technology of pipe bending machine and roller, which is applied in the field of pipe bending of high-pressure oil pipes. It can solve problems such as products not meeting the requirements of drawings, tooling and fixtures cannot be guaranteed, product interference and after-sales, etc., so as to improve competitiveness, reduce claims, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

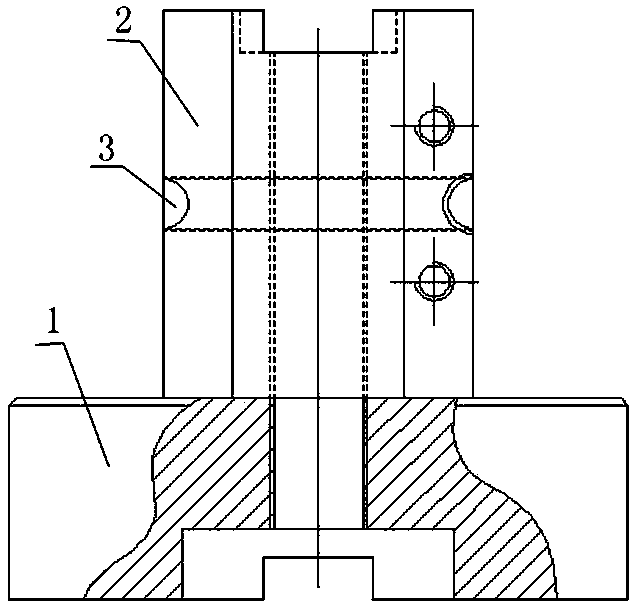

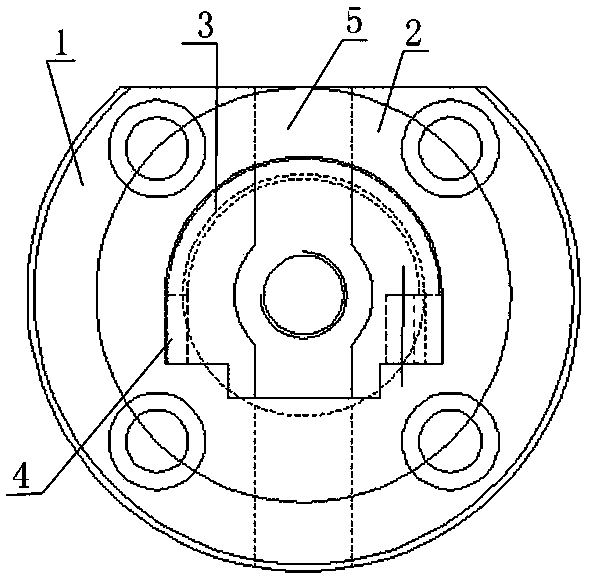

[0014] The present invention as figure 1 , 2 , 3 shown.

[0015] A new type of roller for a pipe bending machine, comprising a roller seat 1, a roller 2 is arranged on the roller seat 1, a guide groove 3 is arranged on the journal of the roller 2 in the circumferential direction, and a linear guide groove 4 is arranged outside the guide groove 3, wherein the linear guide The groove 4 starts from the semicircular line of the journal of the roller 2, and there is a sunken step 5 outside the linear guide groove 4. At this time, the roller 2 forms a stepped roller with an arc surface on one side and a sunken step on the other. .

[0016] The arc surface of the roller 2 is vertically provided with a process groove 6 perpendicular to the semicircle line, and the process groove 6 divides the roller into a structure with guide grooves 3 on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com