A peeling device for cable processing

A cable and bottom plate technology, which is applied in the field of stripping devices for cable processing, can solve the problems of cable stripping without setting springs, and does not take into account the easy wear and break of the blade, so as to increase practicability and solve the effects of easy wear and break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

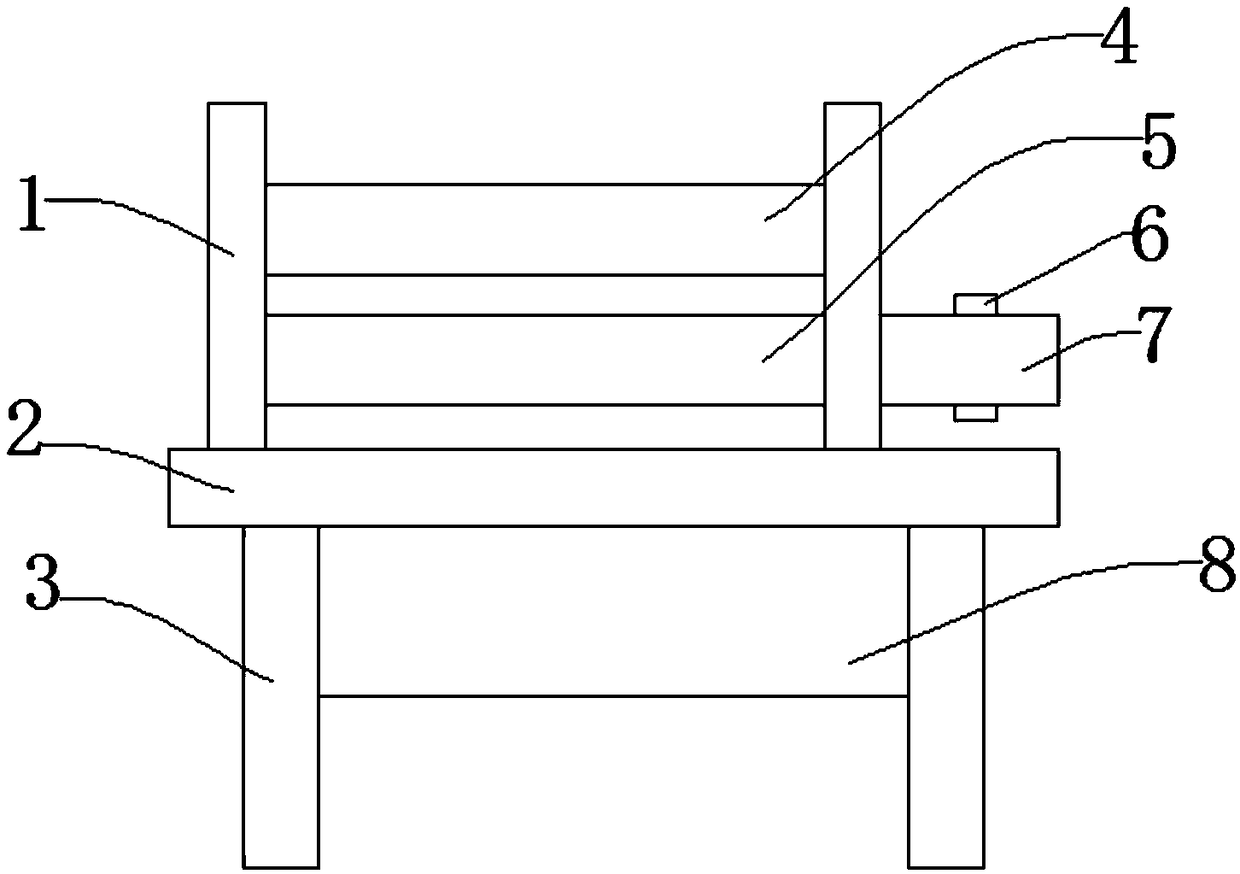

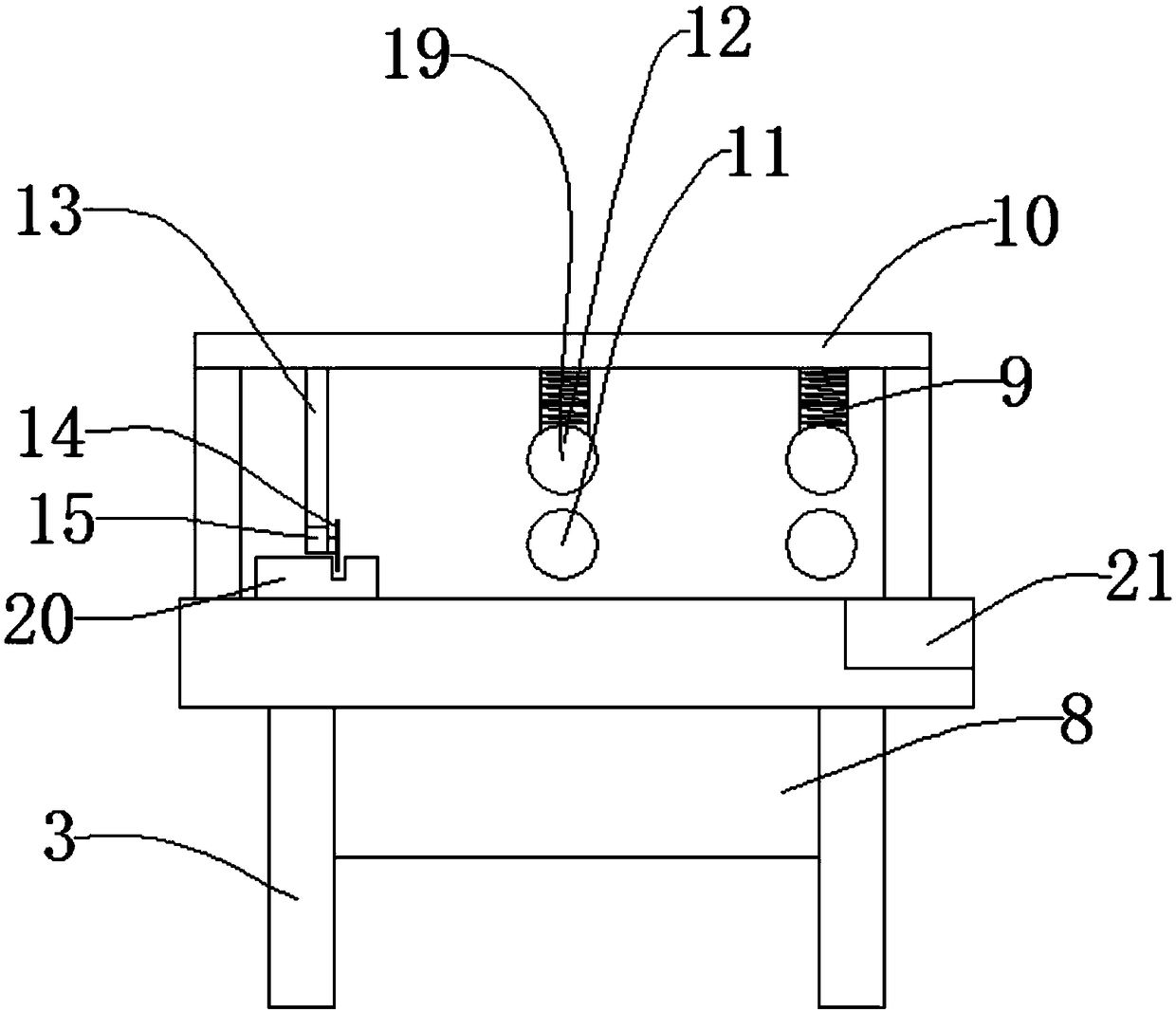

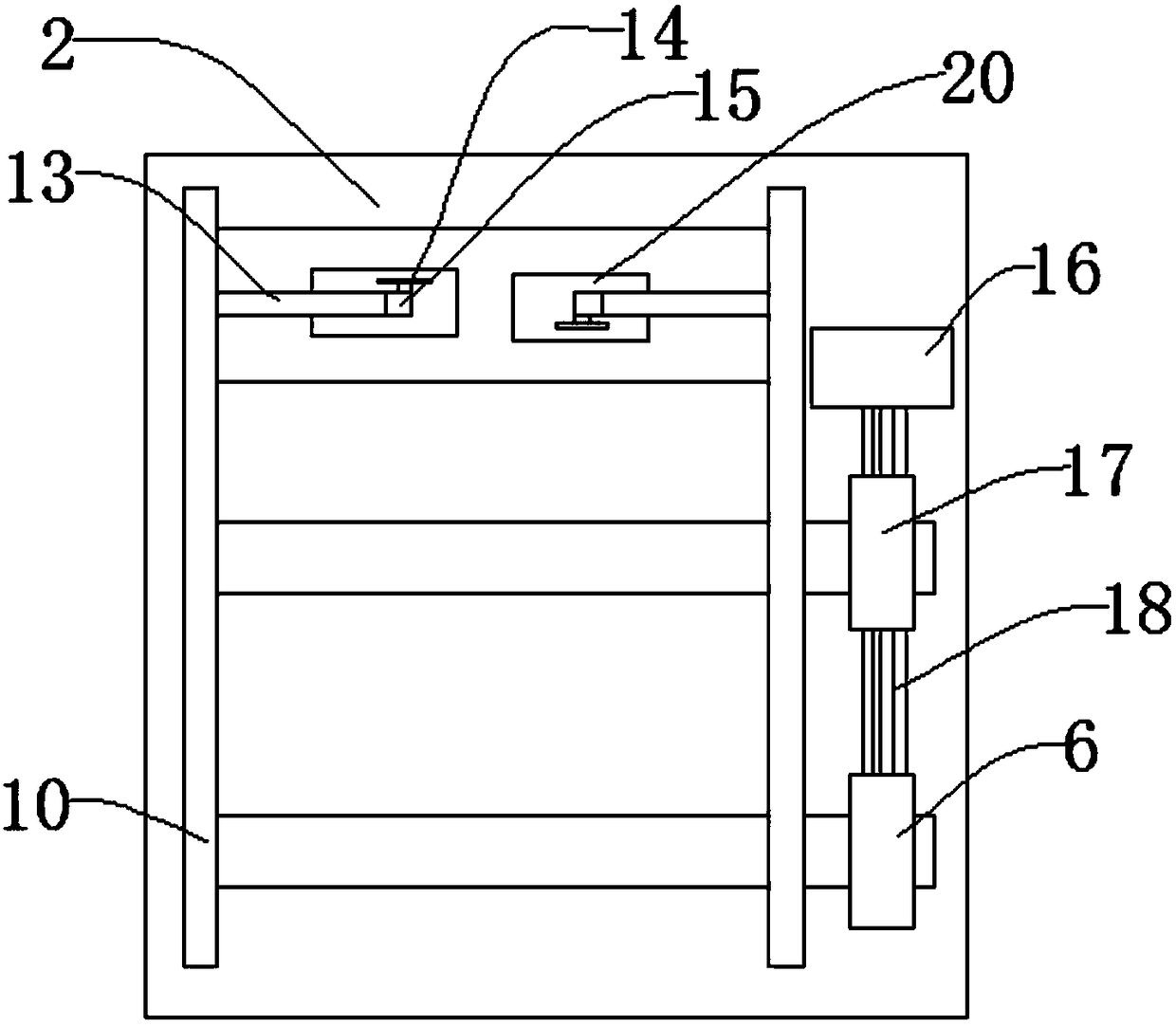

[0028] Such as Figure 1-Figure 4 As shown, a stripping device for cable processing includes a base plate 2, a first spring 9, and a control panel 21, the front portion of the base plate 2 is provided with a control panel 21, the lower part of the base plate 2 is provided with a control box 8, and the control box 8 is provided around There are support legs 3, and the support legs 3 are used to support the whole device. The upper part of the base plate 2 is provided with a support plate 1, and the top of the support plate 1 is provided with a support rod 10. The lower part of the support rod 10 is provided with a first spring 9, and the first spring 9 is used for Adjust the distance between the upper roller knife 4 and the lower hob 5. The lower part of the first spring 9 is provided with an upper hob 4. The upper hob 4 is used to cut off the outer skin of the cable. The lower part of the upper hob 4 is provided with a lower hob 5. The lower hob 5 is used to cut off the outer s...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that in this embodiment, the upper hob 4 is connected to the support plate 1 through a bearing, and the lower hob 5 is connected to the support plate 1 through a bearing.

[0031] Specifically, such setting can solve the problem that the blade is easy to wear and break.

[0032] The specific working principle of the present invention is: open the control panel 21, the drive motor 16, the motor 15, and the control box 8 start to work. It is cut open, but the metal wire inside is not separated from the outer skin, and the hob is used to replace the traditional blade for peeling, which solves the problem that the blade is easy to wear and break. The upper hob 4 and the lower hob can be adjusted through the first spring 9. The distance between the hobs 5 realizes the peeling of cables of different thicknesses, which increases the practicability of the device, and then the cables that are cut off will enter between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com