Fault diagnosis method for automobile generator bearing

An automobile generator and generator bearing technology, which is applied in the testing of mechanical components, electrical digital data processing, and testing of machine/structural components, etc., can solve the problems of non-stationary vibration signals, noise pollution, weak impact of bearing faults, etc. Achieve the effect of improving the signal-to-noise ratio, suppressing noise, and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

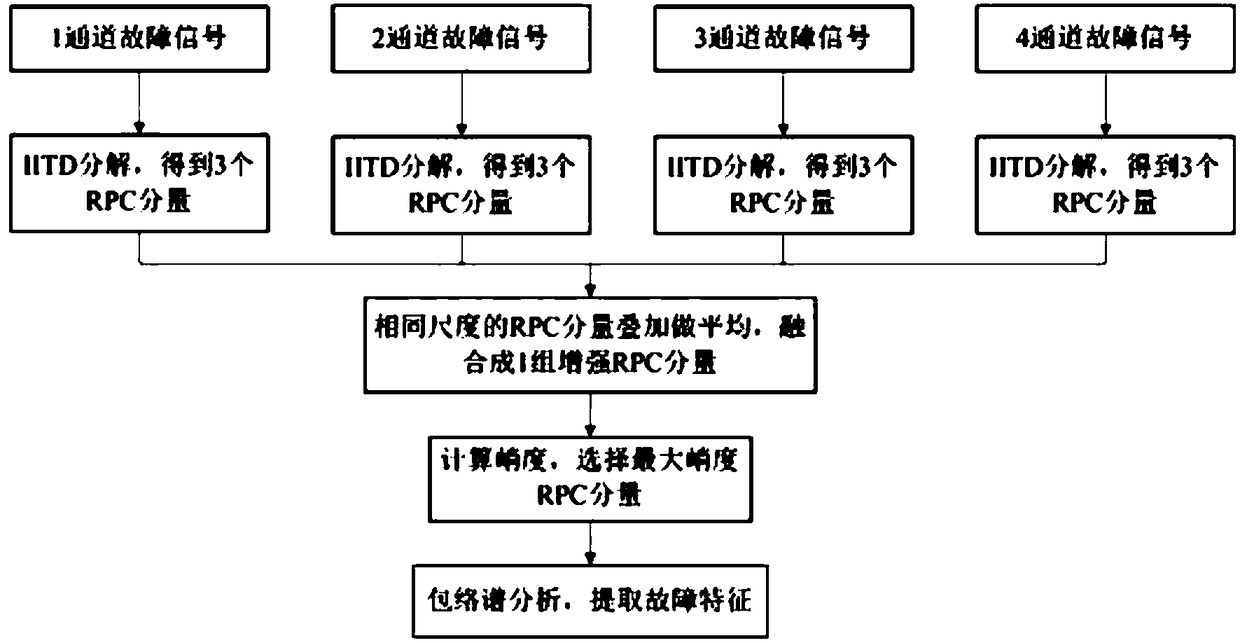

[0077] Implementation Case 1: Fault Diagnosis of Outer Race of Automobile Generator Bearing

[0078] The model of the faulty bearing is 6205, and the basic information is as follows: the number of rolling elements is n=9, the diameter of the rolling elements is d=7.94mm, and the pitch diameter of the bearing is D=39.0398mm. The test parameters are as follows: bearing no-load running speed Rev = 1800r / min, sampling frequency f s = 12kHz. According to the calculation formula of the fault characteristic frequency of the outer ring of the bearing:

[0079]

[0080] In formula (10), α represents the bearing contact angle, and the calculated characteristic frequency of the outer ring fault is 107.5 Hz.

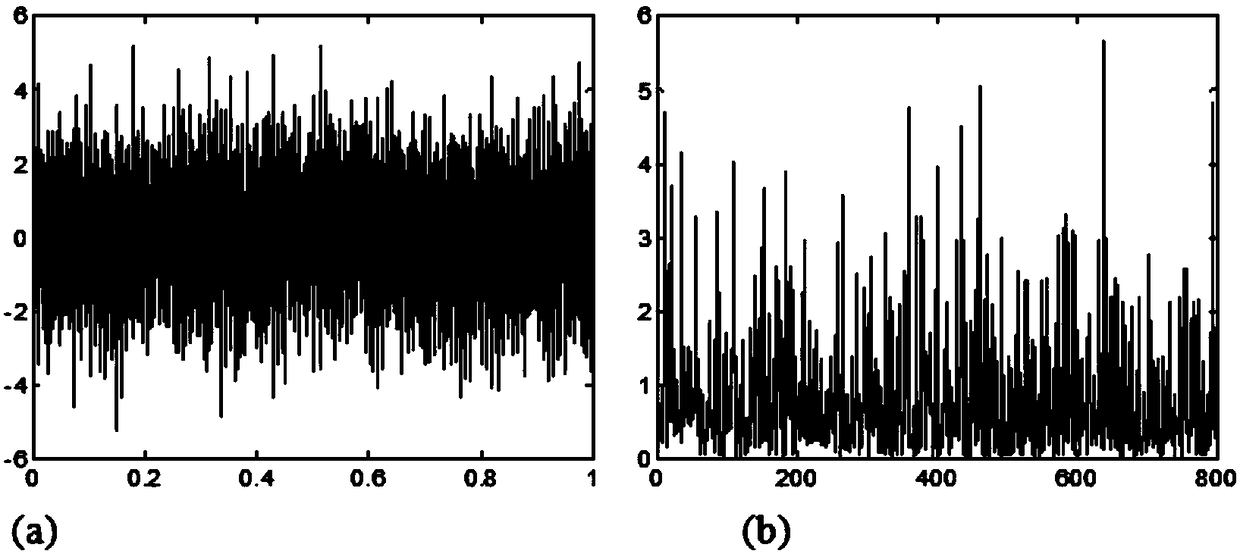

[0081] The time-domain waveform and the Hilbert envelope spectrogram of the original signal in the outer circle are as follows: figure 2 As shown, it can be seen that the spectrum lines of the envelope spectrum are messy, and the fault type cannot be determined. The IITD dec...

Embodiment example 2

[0082] Implementation Case 2: Bearing Inner Ring Fault Diagnosis

[0083] Take the above bearing inner ring fault signal, bearing no-load running speed Rev=1800r / min, sampling frequency f s =12kHz, the formula for calculating the fault characteristic frequency of the inner ring of the bearing is:

[0084]

[0085]By calculation, the characteristic frequency of the inner ring fault is 162.5Hz.

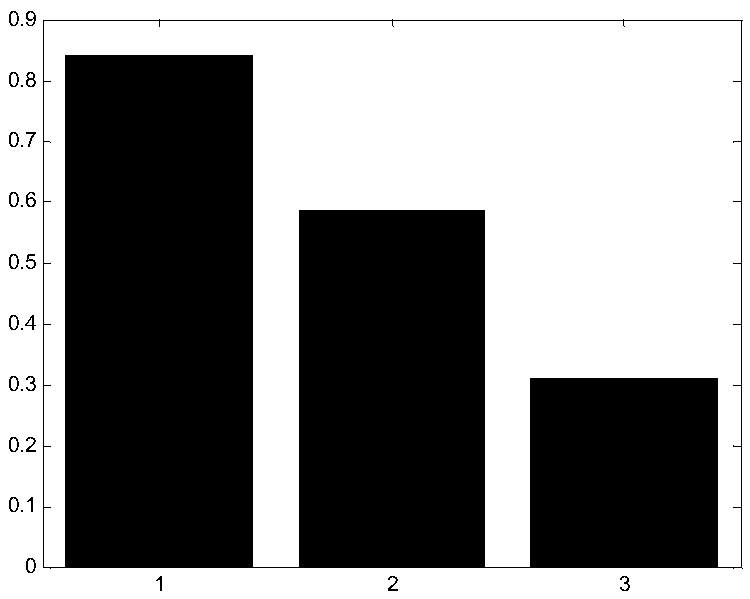

[0086] The time-domain waveform and Hilbert envelope spectrogram of the original signal in the inner circle are as follows: Figure 5 As shown, due to noise interference, no matter in time domain or frequency domain, the fault type cannot be judged. The IITD decomposition is performed on the 4-channel original signal, the number of decomposition layers is 4, and the residual items are removed to obtain 12 intrinsic rotation components in 4 groups. The components of the same scale are superimposed and averaged to obtain the enhanced PRC component. Calculate the autocorrelation coe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com