Visual experiment device and method for simulated cross fracture seepage

A test device, cross-fissure technology, applied in fluid dynamics test, measuring device, testing of machine/structural components, etc., can solve problems such as unfavorable scientific research and engineering activities, single crack, unobservable, etc., to achieve unattended Automatic collection of simple and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

[0037] The technical problem to be solved by the present invention is to provide a cross-fissure seepage visualization test device with simple structure, low cost, strong practicability and scalability, which not only realizes the visualization and quantitative observation of the fissure seepage process, but also has three-dimensional and multi-angle Real-time observation function and test function under different gravity gradients.

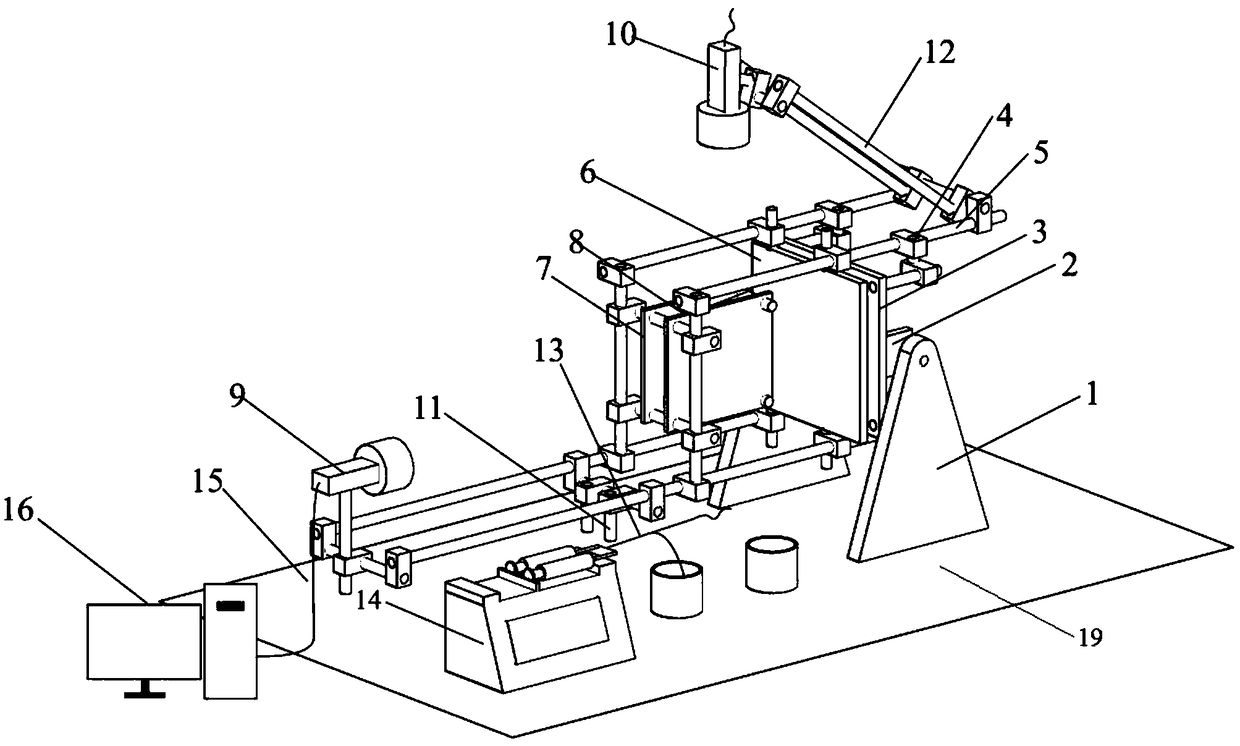

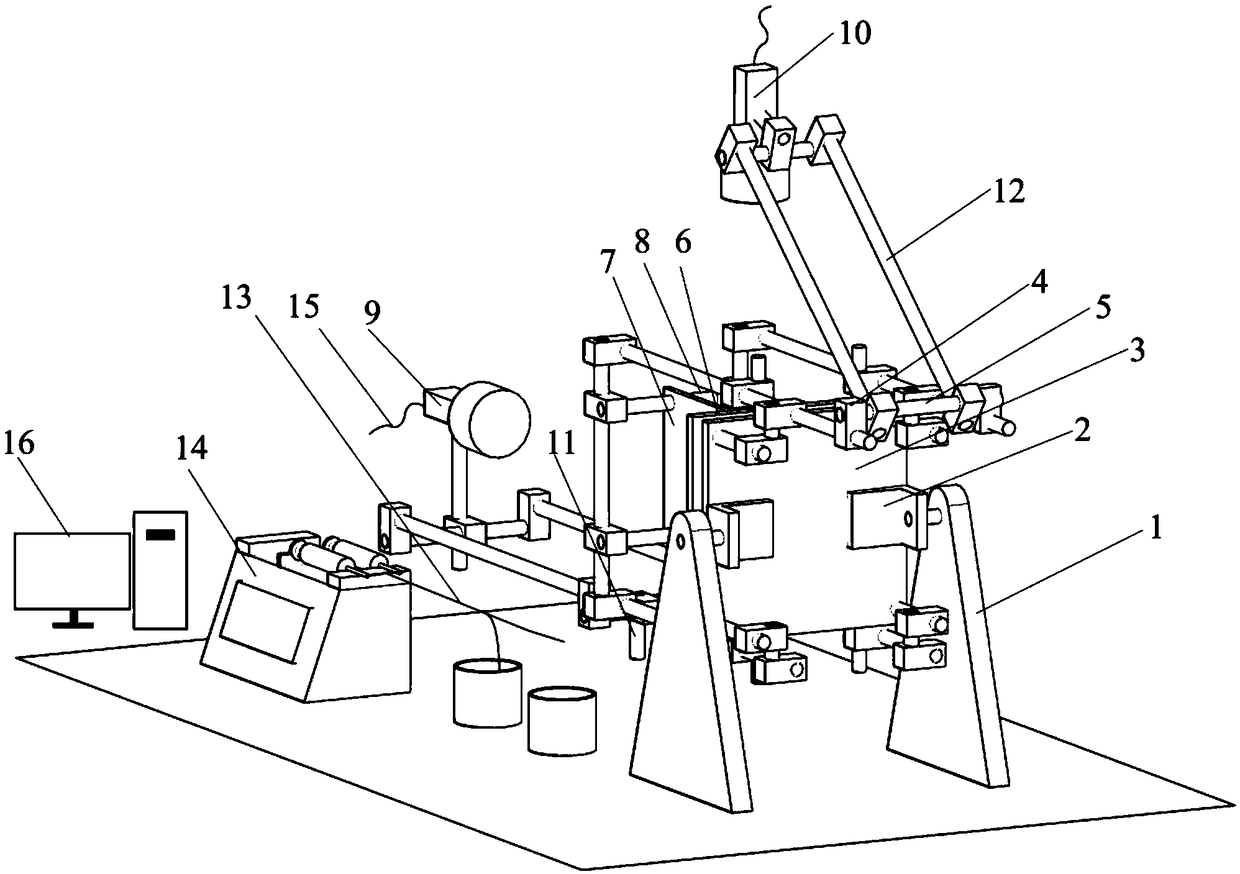

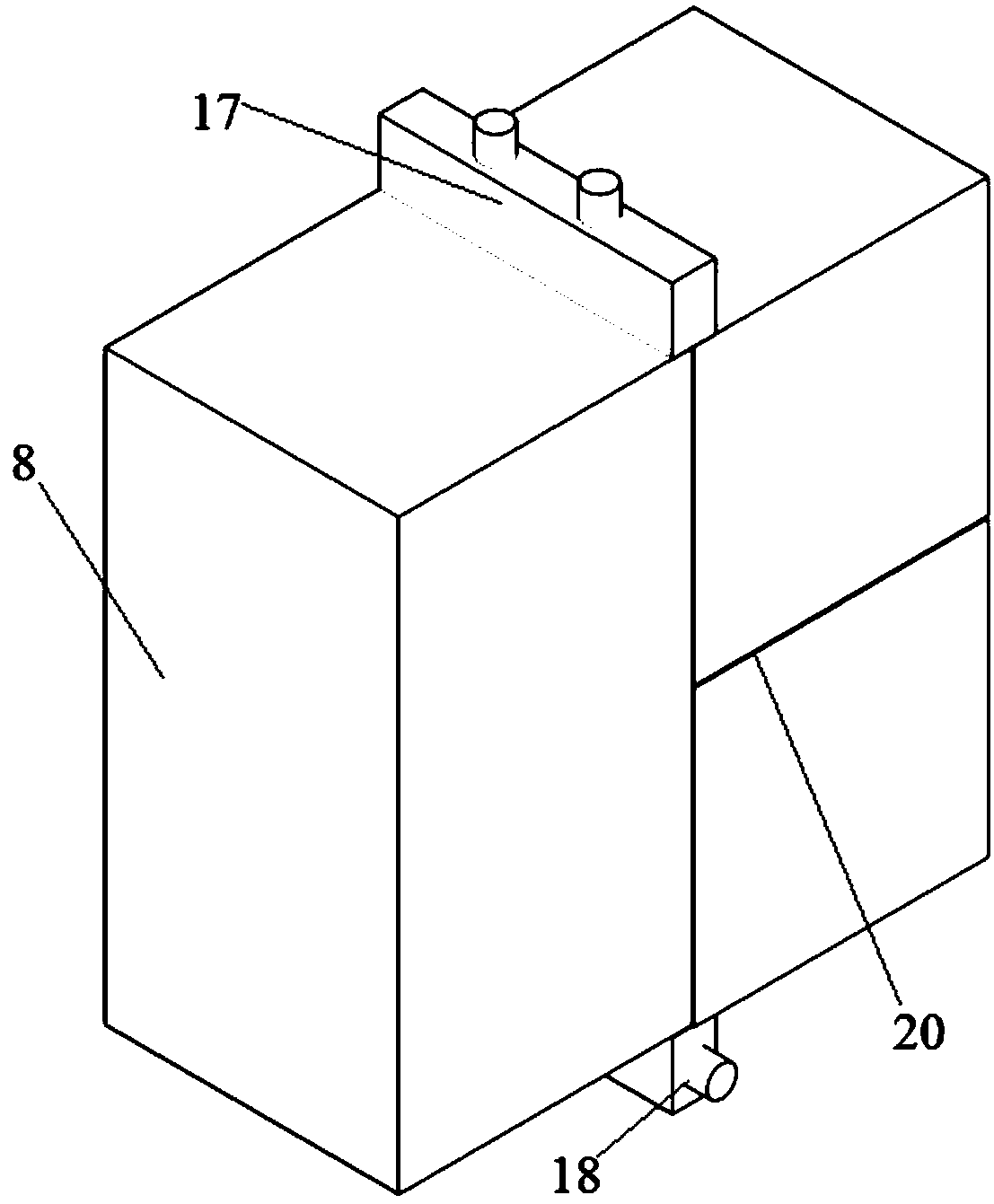

[0038]The visual test device for simulating cross-fissure seepage of the present invention includes a reference plate 3, a support plate 1, a base 19, a transparent fissure mold 8, a horizontal camera 10, a vertical camera 9, a fixed frame, a liquid supply system and a control host 16. The reference plate 3 is installed on the top of the two support plates 1 through the rotating shaft, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com