Float indicator and manufacturing method thereof

An indicator and floating technology, which is applied in the direction of the level indicator of level members, can solve the problems of diffusion, poisoning of inspectors, etc., and achieve the effects of eye-catching signs, simple installation, and avoiding gas diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

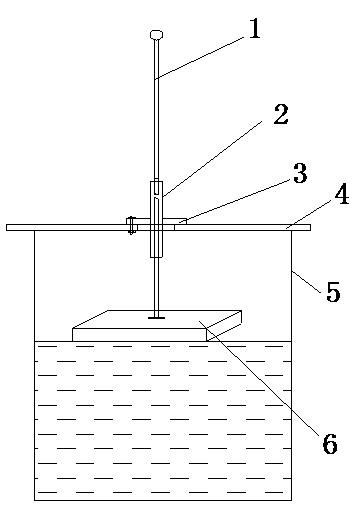

[0017] The 3# gas tank sump part under the jurisdiction of the gas tank operating area of the energy and power plant of the present invention has been implemented.

[0018] The specific implementation method is as follows:

[0019] 1. Make a butt-type sign pole, which is made of DN15mm stainless steel pipe. The length of the stainless steel pipe is 1000mm. One end of the stainless steel pipe is provided with an external thread, and the other end is provided with an internal thread;

[0020] 2. To make the float, use stainless steel with a thickness of 0.5mm~1mm to make a sealed box (size: 300 mm×600 mm×100 mm), and fill the inside of the sealed box with foam. The upper plane of the sealed box body is provided with a sign post installation hole.

[0021] (In order to facilitate the sealing of the box, the two sides of the box are provided with butt holes, and multi-piece connection and assembly can be carried out according to the requirements of on-site use).

[0022] 3. Ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com