Kinetic scroll plate driving component of scroll compressor, scroll compressor and air conditioner

A scroll compressor and moving scroll technology, applied in the field of compressors, can solve the problems of reduced compressor reliability, large eccentric load of the main shaft, and large deflection stress, etc., to reduce eccentric load and deflection deformation, and reduce bearing Good wear and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The air conditioner provided by the present invention includes a scroll compressor. Since the point of the invention lies in the scroll compressor, the structure of the scroll compressor will be described in detail below.

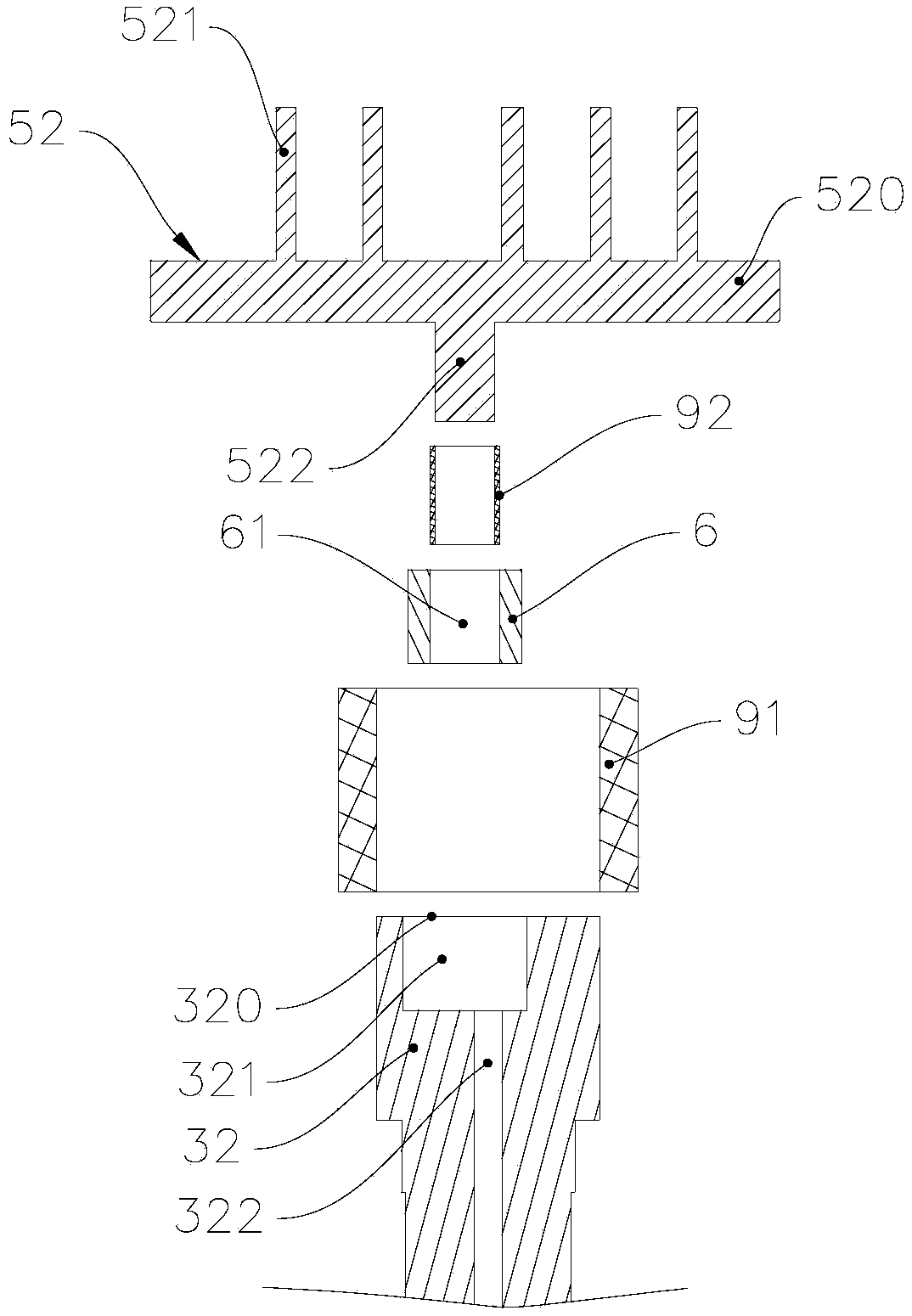

[0039] see figure 1 and figure 2 , figure 1 It is a sectional view of an embodiment of a scroll compressor of the present invention, figure 2 It is a sectional view of the partial structure of the embodiment of the scroll compressor of the present invention.

[0040] The scroll compressor consists of a casing 1, a drive motor 2, a main shaft 3, a bracket 4, a fixed scroll 51, a movable scroll 52, a slider 6, a lower bracket 7, a counterweight 8, a first bearing 91, a second The bearing 92, the third bearing 93, the anti-rotation mechanism 94 and the thrust bearing 95 are composed, and the movable scroll 52, the main shaft 3, the drive motor 2 and the first bearing 91 constitute the movable scroll drive assembly in the present invention. The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com