Transfer-printing method and printed article

A technology of transfer printing and transfer paper, applied in the field of printing and dyeing, can solve the problems of weak light resistance, color transfer, damage to the hand feeling, etc., and achieve the effects of excellent firmness, low environmental burden, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

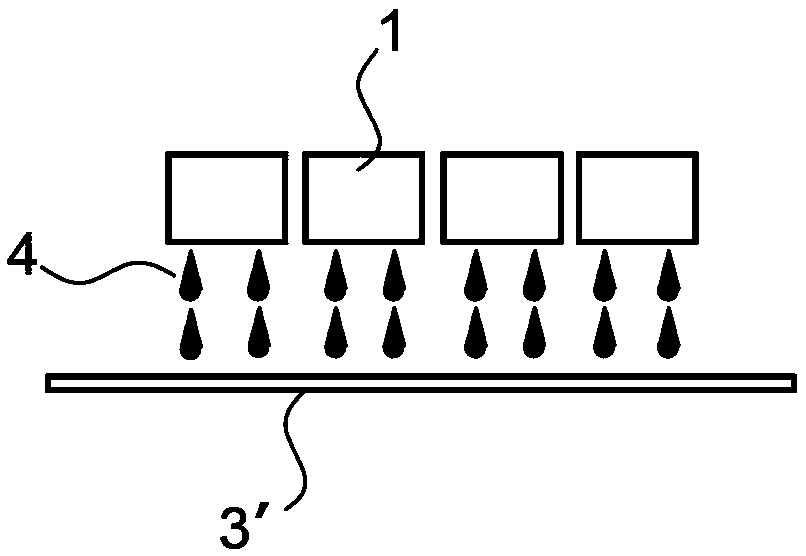

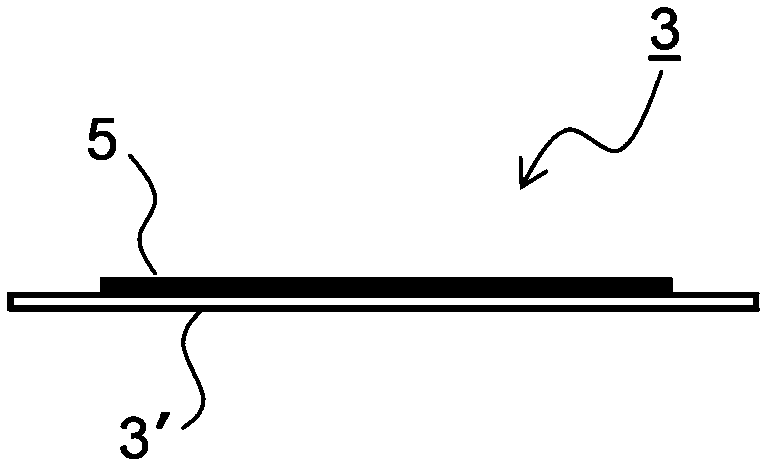

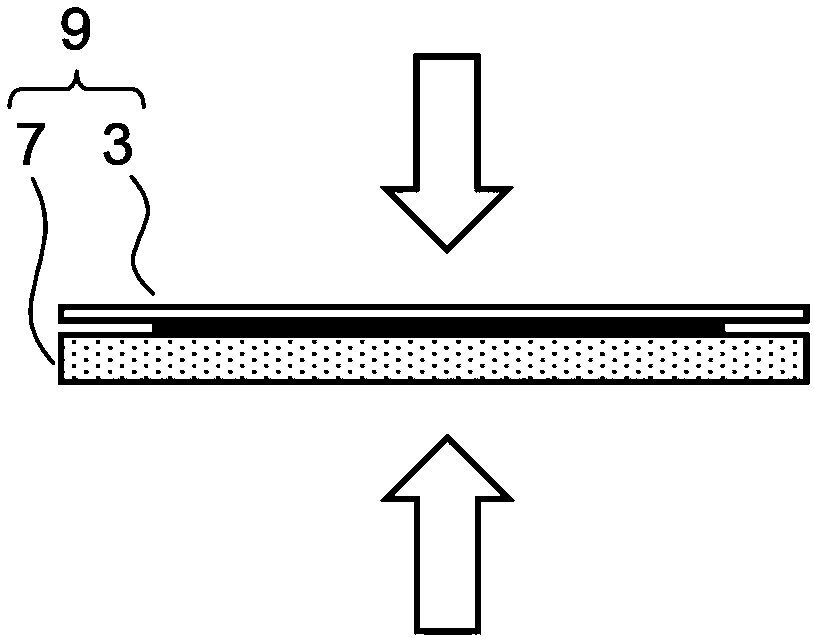

Method used

Image

Examples

Embodiment 1

[0072] (Preparation of Pigment Dispersion)

[0073] Mix 20% by mass of phthalocyanine pigment (pigment blue 15:3), 5% by mass of styrene acrylic resin (molecular weight: 5000) as a dispersion stabilizer, and 75% by mass of ion-exchanged water, and use a film rotary high-speed stirrer (FILMIX ( Filmix), manufactured by Plaimix Co., Ltd. (Plaimix Co., Ltd.), was dispersed at a high speed, and then dispersed with a bead mill (Dynomyl Mill, manufactured by Sinmaru Enterprise Plaises Co., Ltd.) until the particle size became 80 nm, thereby preparing a pigment Dispersions. The viscosity of the pigment dispersion is 8 mPas.

[0074] (Preparation of ink for transfer printing and dyeing)

[0075] As shown in Table 1, the previously prepared pigment dispersion was mixed so that the pigment component became 5% by mass, propylene glycol and glycerin were mixed as a water-soluble solvent, and Surfinol 104 (SURFYNOL 104, acetylene glycol-based surface active agent) was mixed as a surfacta...

Embodiment 2

[0097] (Preparation of water-insoluble polymer solution)

[0098] Nitrogen replacement in the reaction vessel was carried out, and the monomers, solvents, and polymerization initiators shown in Table 2 were added and mixed to obtain the initial monomer solution and the dropwise monomer solution.

[0099] [Table 2]

[0100]

[0101] Under a nitrogen atmosphere, the initially charged monomer solution in the reaction vessel was maintained at 75°C while stirring, and the dropwise monomer solution shown in Table 2 was gradually added dropwise into the reaction vessel over 3 hours. After completion of the dropwise addition, the mixed solution in the reaction vessel was stirred at 75° C. for 2 hours. Next, a polymerization initiator solution obtained by dissolving 2 parts by mass of a polymerization initiator in 130 parts by mass of methyl ethyl ketone was added to the mixed solution, and the mixture was stirred at 75° C. for 1 hour to perform aging. Next, the reaction solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com