Produced vehicle-mounted concrete tank body steel board and production method thereof

A production method and concrete technology, applied in the field of metallurgy, can solve problems such as poor wear resistance and short service life, and achieve the effects of reduced production costs, low production costs, excellent mechanical properties and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

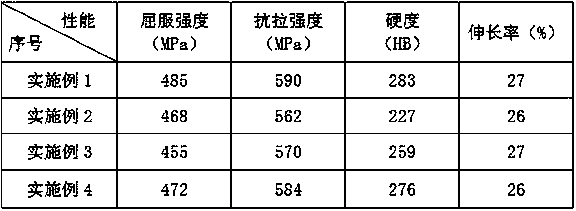

Examples

Embodiment 1

[0029] In this embodiment, the thickness of the steel plate for the vehicle-mounted concrete tank is 2.0 mm, and its chemical composition and mass percentage are: C: 0.15%, Si: 0.10%, Mn: 1.35%, P: 0.011%, S: 0.003%, Cu: 0.20%, Ti: 0.010%, Als: 0.020%, N: 0.0042%, and the balance is Fe and unavoidable impurities.

[0030] The production method for making steel plates for vehicle-mounted concrete tanks in this embodiment includes slab heating, high-pressure water descaling, controlled rolling and curling processes, and the specific process steps are as follows:

[0031] (1) Slab heating process: heating the slab to 1180°C;

[0032] (2) High pressure water descaling process: dephosphorization water pressure is 18.0MPa;

[0033] (3) Controlled rolling process: rough rolling is rolled by 5 rolling mills, and the exit temperature is 1060°C; finish rolling is rolled by 7 rolling mills, the finish rolling entrance temperature is 980°C, and the exit temperature is 840°C;

[0034] (4...

Embodiment 2

[0037] In this embodiment, the thickness of the steel plate for the vehicle-mounted concrete tank is 6.0mm, and its chemical composition and mass percentage are: C: 0.17%, Si: 0.15%, Mn: 1.42%, P: 0.013%, S: 0.005%, Cu: 0.25%, Ti: 0.019%, Als: 0.035%, N: 0.0040%, and the balance is Fe and unavoidable impurities.

[0038] The production method for making steel plates for vehicle-mounted concrete tanks in this embodiment includes slab heating, high-pressure water descaling, controlled rolling and curling processes, and the specific process steps are as follows:

[0039] (1) Slab heating process: heating the slab to 1220°C;

[0040] (2) High-pressure water descaling process: the pressure of phosphorus removal water is 19.0MPa;

[0041] (3) Controlled rolling process: rough rolling is rolled by 5 rolling mills, and the exit temperature is 1020°C; finish rolling is rolled by 7 rolling mills, the entrance temperature of finish rolling is 1000°C, and the exit temperature is 860°C; ...

Embodiment 3

[0045] In this embodiment, the thickness of the steel plate for the vehicle-mounted concrete tank is 10.0 mm, and its chemical composition and mass percentage are: C: 0.18%, Si: 0.20%, Mn: 1.50%, P: 0.015%, S: 0.010%, Cu: 0.21%, Ti: 0.025%, Als: 0.030%, N: 0.0060%, and the balance is Fe and unavoidable impurities.

[0046] The production method for making steel plates for vehicle-mounted concrete tanks in this embodiment includes slab heating, high-pressure water descaling, controlled rolling and curling processes, and the specific process steps are as follows:

[0047] (1) Slab heating process: heating the slab to 1240°C;

[0048] (2) High pressure water descaling process: dephosphorization water pressure is 22.0MPa;

[0049] (3) Controlled rolling process: rough rolling is rolled by 5 rolling mills, and the exit temperature is 1060°C; it is coiled by a hot coil box; the finish rolling is rolled by 7 rolling mills, the finish rolling entrance temperature is 1030°C, and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com