A brewing method of Chinese wolfberry fruit wine

A technology of wolfberry fruit wine and dried wolfberry fruit, which is applied in the field of food processing, can solve the problems that the taste is difficult to achieve an ideal effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

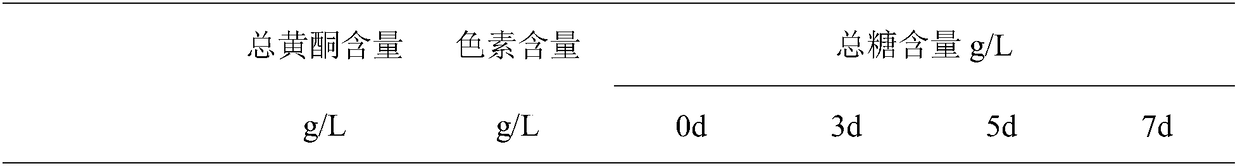

[0053] Pick 5 kg of complete dried wolfberry fruit, remove impurities, and crush. Add the crushed Lycium barbarum to 15kg of water and stir evenly, add 0.9g of potassium metabisulfite, and then put it into a high-pressure equipment and treat it at 80°C and 0.18MPa for 10min. After high-pressure treatment and cooling, add 0.6g of pectinase (Shanghai Jietu Industry and Trade Co., Ltd.) and 750g of white sugar to the treatment solution, mix and stir evenly, and add lactic acid at the same time and mix evenly, so that the total acid content in the mixed solution is 4.5g / L (with H 2 SO 4count). Add 0.45g of Saccharomyces cerevisiae (Shanghai Jietu Industry and Trade Co., Ltd.) to the blended slurry, stir evenly, and ferment at 20°C. When the sugar content is less than 4g / L, filter to stop the fermentation to obtain 13.8L of liquor. Potassium metabisulfite and 0.276gVc were added to the filtered wine to make the content of free sulfur dioxide in the wine 20mg / L, while the pH of t...

Embodiment 2

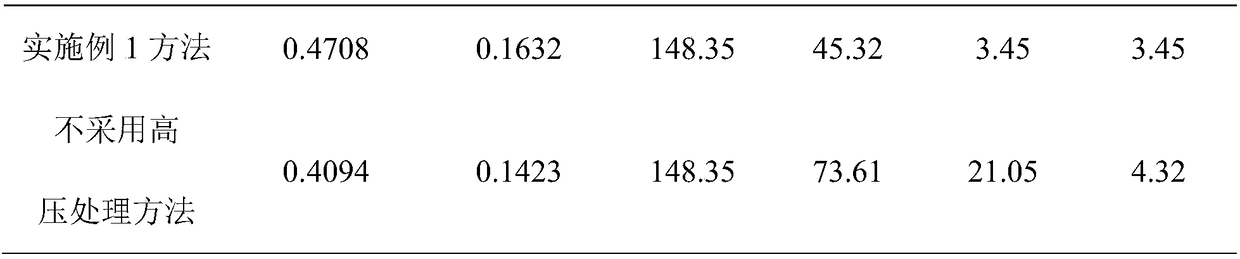

[0063] Select 10kg of complete dried wolfberry fruit, remove impurities and crush. Add the crushed Lycium barbarum to 40kg of water and stir evenly, add 3.2g of potassium metabisulfite, and then put it into high-pressure equipment and treat it at 100°C and 0.15MPa for 15min. After high-pressure treatment and cooling, add 2.0g of pectinase (Shanghai Jietu Industry and Trade Co., Ltd.) and 3200g of white sugar to the treatment solution, mix and stir evenly, and add lactic acid at the same time and mix evenly, so that the total acid content in the mixed solution is 4.8g / L (with H 2 SO 4 count). Add 1.6 g of Saccharomyces cerevisiae (Shanghai Jietu Industry and Trade Co., Ltd.) to the prepared slurry, stir evenly, and ferment at 25°C. When the sugar content is less than 4g / L, filter to stop the fermentation to obtain 37.5L of liquor. Potassium metabisulfite and 1.125gVc were added in the filtered wine, so that the free sulfur dioxide content in the wine was 25mg / L, while the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com