Soil improvement agent, and preparation method thereof

A soil improver and modification technology, which is applied in the direction of soil conditioning materials, chemical instruments and methods, and other chemical processes, can solve the problems of soil nutrient element imbalance and soil compaction, so as to improve acidity, reduce soil compaction, and enrich nutrients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

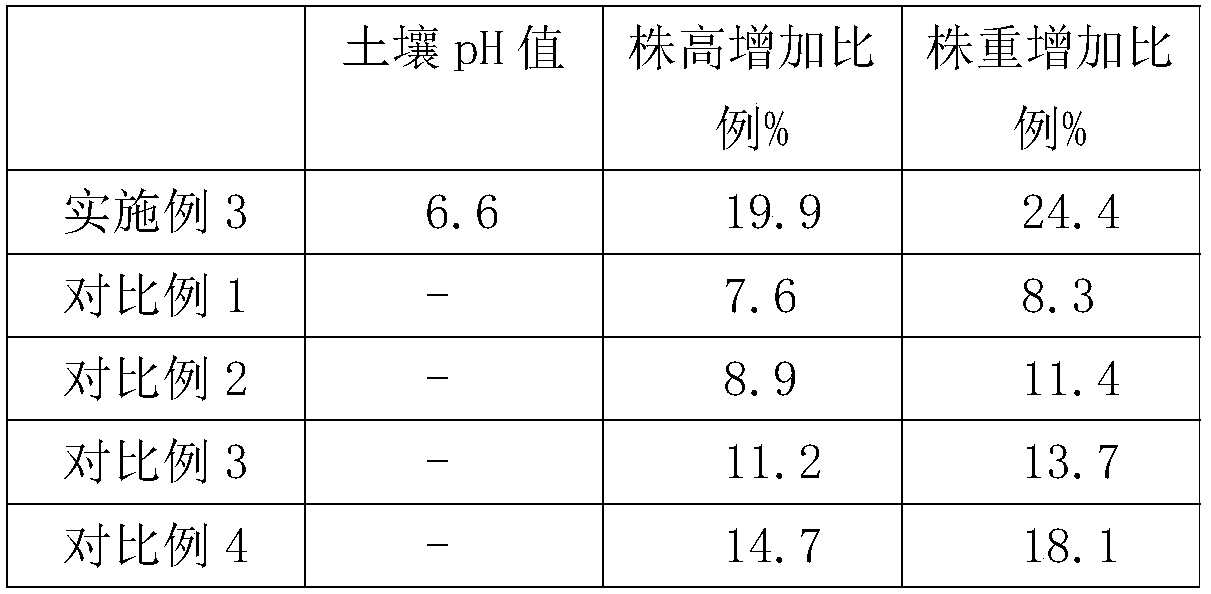

Embodiment 1

[0036] A soil conditioner consisting of the following raw materials:

[0037] 60kg of corn stalk powder, 15kg of walnut shell powder, 20kg of decomposed sawdust, 8kg of modified cyclodextrin, and 2kg of sodium secondary alkyl sulfonate.

[0038] The preparation method of the decomposed sawdust is as follows: sawdust, coconut shell powder and chitosan are mixed uniformly in a mass ratio of 300:30:5, then add 0.6% organic material decomposing agent of the total weight of the mixture, and then adjust the moisture content 30%, stacked and fermented, turned once every 3 days, decomposed after 20 days, dried and set aside.

[0039] The preparation method of described modified cyclodextrin is as follows:

[0040] 1) Mix and swell the bagasse fiber with 0.1mol / L sodium hydroxide solution, the mass ratio of the bagasse fiber to the sodium hydroxide solution is 1:20, swell for 1 hour, and filter to obtain the swollen bagasse fiber;

[0041] 2) Add epichlorohydrin and sodium hydroxide ...

Embodiment 2

[0048] A soil conditioner consisting of the following raw materials:

[0049] 70kg of wheat straw powder, 25kg of walnut shell powder, 15kg of decomposed sawdust, 12kg of modified cyclodextrin, and 5kg of sodium secondary alkyl sulfonate.

[0050] The preparation method of the decomposed sawdust is as follows: sawdust, coconut shell powder and chitosan are mixed evenly in a mass ratio of 400:40:12, then add 0.8% organic material decomposing agent of the total weight of the mixture, and then adjust the moisture content 40%, stacked and fermented, turned over once every 2 days, decomposed after 15 days, dried and set aside.

[0051] The preparation method of described modified cyclodextrin is as follows:

[0052] 1) The kiwifruit fiber is mixed and swollen with 0.1mol / L sodium hydroxide solution, the mass ratio of the kiwifruit fiber to the sodium hydroxide solution is 1:25, swollen for 1h, and filtered to obtain the swollen kiwifruit fiber;

[0053] 2) Add epichlorohydrin and...

Embodiment 3

[0060] A soil conditioner consisting of the following raw materials:

[0061] Wheat straw powder 67kg, walnut shell powder 20kg, decomposed sawdust 18kg, modified cyclodextrin 10kg, sodium secondary alkyl sulfonate 4kg.

[0062] The preparation method of the decomposed sawdust is as follows: sawdust, coconut shell powder and chitosan are mixed evenly in a mass ratio of 330:37:9, then add 0.7% organic material decomposing agent of the total weight of the mixture, and then adjust the moisture content It is 33%, stacked and fermented, turned over once every 2 days, decomposed after 15 days, dried and set aside.

[0063] The preparation method of described modified cyclodextrin is as follows:

[0064] 1) The kiwifruit fiber is mixed and swollen with 0.1mol / L sodium hydroxide solution, the mass ratio of the kiwifruit fiber to the sodium hydroxide solution is 1:25, swollen for 1h, and filtered to obtain the swollen kiwifruit fiber;

[0065] 2) Add epichlorohydrin and sodium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com