Method for preparing high-purity N-acetylneuraminic acid hydrate by supersaturation crystallization process

An acetylneuraminic acid and high-purity technology, which is applied in the field of preparing high-purity N-acetylneuraminic acid hydrate, can solve the problems of high price, difficulty in purity, unfavorable application of N-acetylneuraminic acid, etc., and achieves good quality, Simple process and stable crystal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the method for preparing high-purity N-acetylneuraminic acid dihydrate by supersaturated crystallization method is as follows:

[0024] 1. Preheat the pure water to 50°C, then add 70% N-acetylneuraminic acid to prepare a supersaturated aqueous solution of N-acetylneuraminic acid with a concentration of 250g / L;

[0025] 2. Filtrate the supersaturated aqueous solution of N-acetylneuraminic acid obtained in step 1 while it is hot, and the filter membrane is 0.22um to remove a small amount of impurities;

[0026] 3. The supersaturated aqueous solution of N-acetylneuraminic acid after filtration is naturally cooled, then left to crystallize at 4°C, and matured for 24 hours after the crystals are precipitated, and then the crystal mother liquor is separated, and the separated crystals are washed with absolute ethanol for two Once dried at 100°C, N-acetylneuraminic acid dihydrate can be obtained.

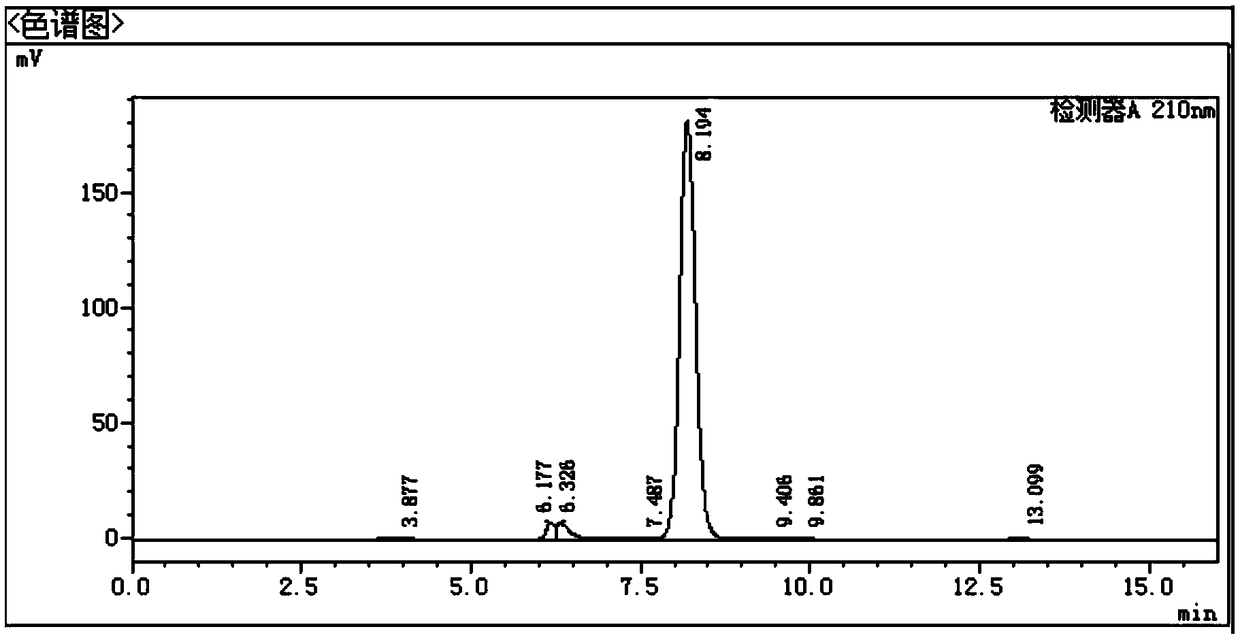

[0027] Detected by high performance liquid chromatography,...

Embodiment 2

[0029] In this example, the method for preparing high-purity N-acetylneuraminic acid hydrate by supersaturated crystallization method is as follows:

[0030] 1. Preheat pure water to 60°C, then add N-acetylneuraminic acid with a content of 85% to prepare a supersaturated aqueous solution of N-acetylneuraminic acid with a concentration of 300g / L;

[0031] 2. Filtrate the supersaturated aqueous solution of N-acetylneuraminic acid obtained in step 1 while it is hot, and the filter membrane is 0.45um to remove a small amount of impurities;

[0032] 3. The supersaturated aqueous solution of N-acetylneuraminic acid after filtration is cooled naturally, then left to crystallize at 10°C, and matured for 36 hours after the crystals are precipitated, and then the crystal mother liquor is separated, and the separated crystals are quickly washed with pure water for two Once dried at 80°C, N-acetylneuraminic acid dihydrate can be obtained.

[0033] Detected by high performance liquid chro...

Embodiment 3

[0035] This implementation follows the steps of Example 2, except that the aqueous solution concentration of N-acetylneuraminic acid in step 1 is 40g / l, other conditions are the same as the steps of Example 4, and finally there is no crystallization of N-acetylneuraminic acid dihydrate .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com