Safety production process of diethylhexyl peroxydicarbonate initiator

A technology of diethylhexyl peroxydicarbonate and initiators, which is applied in the safe production process field of diethylhexyl peroxydicarbonate initiators, can solve the unreasonable construction of cold storage for peroxide initiators and cause Avoid problems such as unstable agent emulsion and poor ventilation of material barrels, so as to avoid personal accidental injury and property loss, improve air cooling effect, and facilitate procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

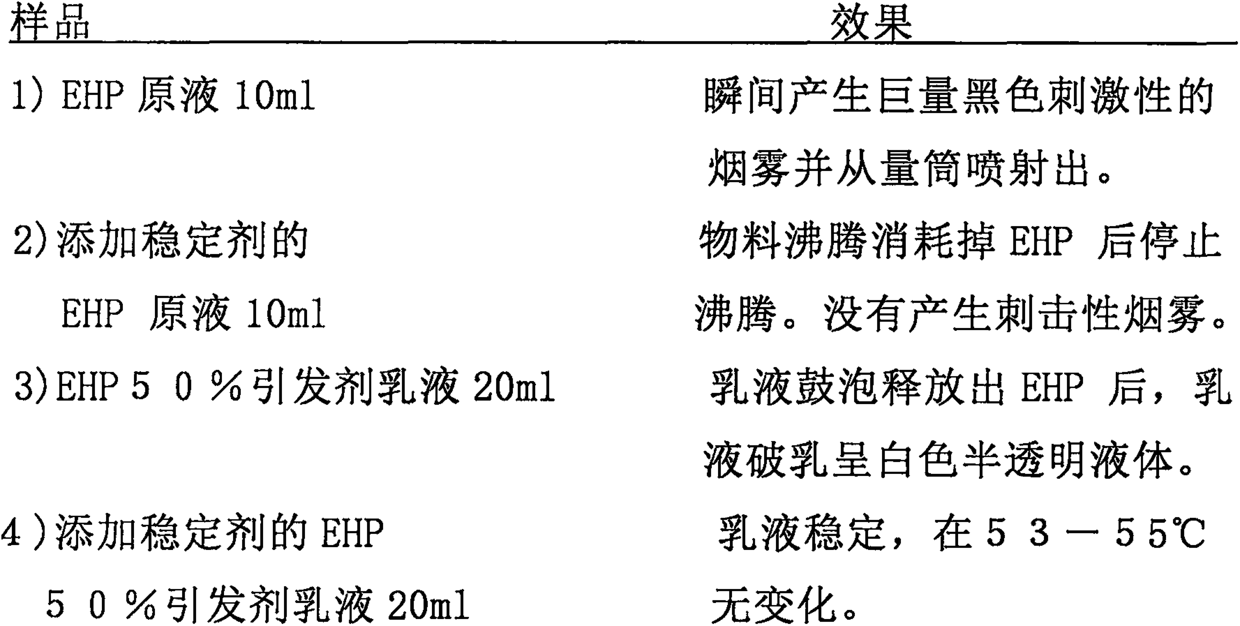

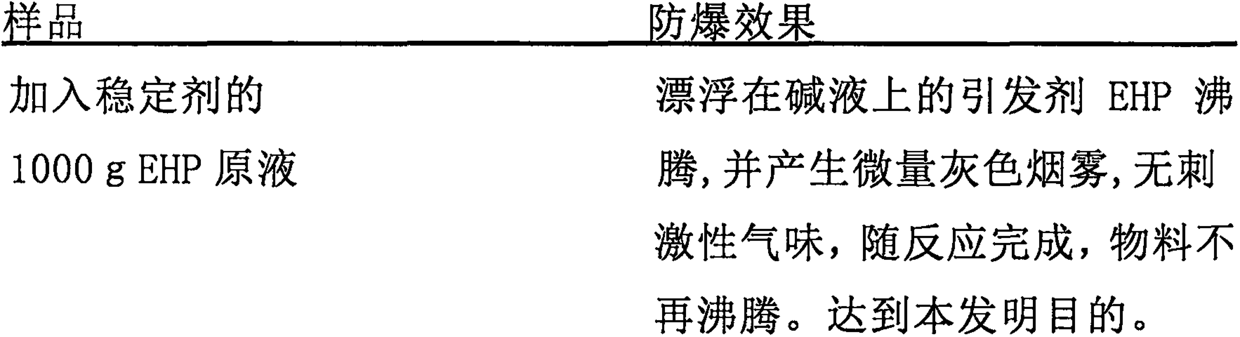

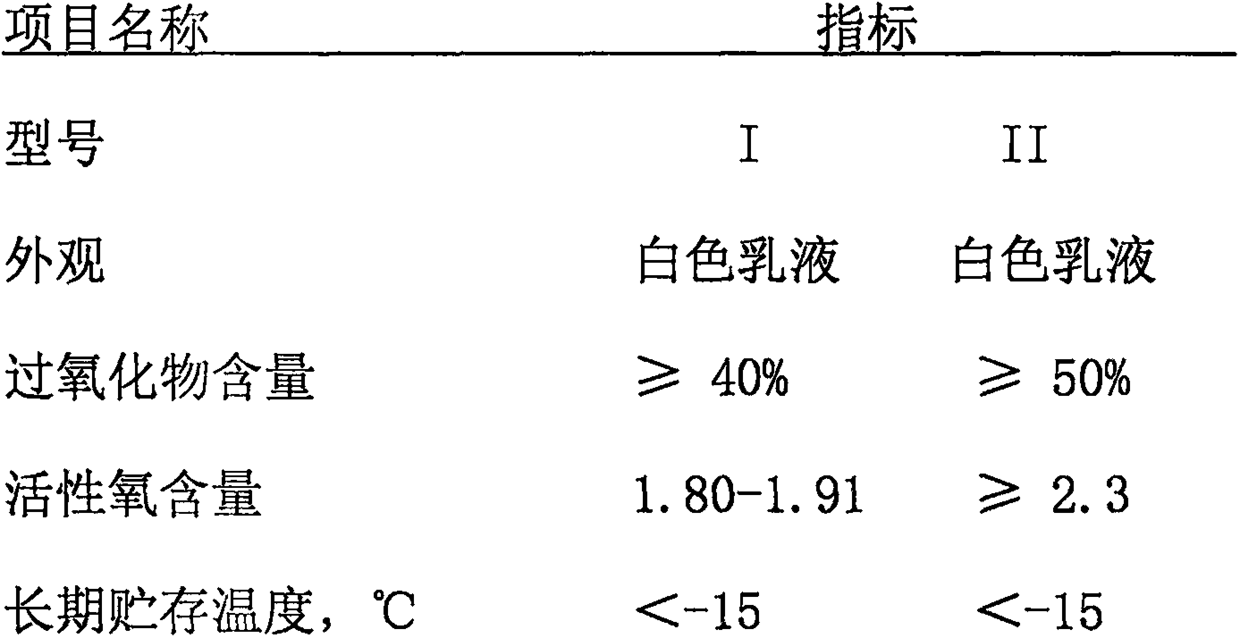

Examples

Embodiment 1

[0029] A diethylhexyl peroxydicarbonate initiator is prepared from the following raw materials in parts by weight: 35 parts of chlorinated esters, 15 parts of hydrogen peroxide, and 5 parts of sodium hydroxide.

[0030] After checking that the equipment is in good condition, check that the initiator stabilizer has been put into the safety tank for standby.

[0031] First, put deionized water into the reaction kettle according to the process formula, and start the agitator. Add 5 parts of caustic soda weighed into the reaction kettle from the feeding port, open the refrigerant valve, start stirring, and start to add 15 parts of hydrogen peroxide into the reaction kettle to produce sodium peroxide.

[0032] Then, the flow meter was opened again, and 35 parts of chlorinated esters were slowly added to the reactor. In this step, the reaction is exothermic very quickly. Once the temperature rises rapidly, it is difficult to control, indicating that the feeding speed is too fast, a...

Embodiment 2

[0035] A diethylhexyl peroxydicarbonate initiator is prepared from the following raw materials in parts by weight: 45 parts of chlorinated esters, 17.5 parts of hydrogen peroxide, and 7.5 parts of sodium hydroxide.

[0036] After checking that the equipment is in good condition, check that the initiator stabilizer has been put into the safety tank for standby.

[0037] First, put deionized water into the polymerization kettle according to the process formula, and start the agitator. Add 7.5 parts of caustic soda weighed into the reaction kettle from the feeding port, and open the refrigerant valve. The flow meter was turned on and 17.5 parts of hydrogen peroxide was started to be added to the kettle to produce sodium peroxide.

[0038]Then, the flowmeter was opened again, and 45 parts of chlorinated esters were slowly added to the reactor. In this step, the reaction is exothermic very quickly. Once the temperature rises rapidly, it is difficult to control, indicating that th...

Embodiment 3

[0040] A diethylhexyl peroxydicarbonate initiator is prepared from the following raw materials in parts by weight: 55 parts of chlorinated esters, 20 parts of hydrogen peroxide, and 8 parts of sodium hydroxide.

[0041] After checking that the equipment is in good condition, check that the initiator stabilizer has been put into the safety tank for standby.

[0042] First, put deionized water into the reaction kettle according to the process formula, and start the agitator. Add 8 parts of caustic soda weighed into the reaction kettle from the feeding port, open the refrigerant valve, and start stirring. Turn on the flow meter and start adding 20 parts of hydrogen peroxide to the reactor to produce sodium peroxide.

[0043] Then, the flow meter was opened again, and 55 parts of chlorinated esters were slowly added to the reactor. In this step, the reaction is exothermic very quickly. Once the temperature rises rapidly, it is difficult to control, indicating that the feeding sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com