Quadruped robot and leg joint structure

A quadruped robot and joint structure technology, applied in the field of robotics, can solve the problems of limited hydraulic cylinder stroke, difficulty in passing tasks for high-load quadruped robots, and insufficient joint flexibility, achieving reasonable stress, shortened dynamic response time, smooth motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

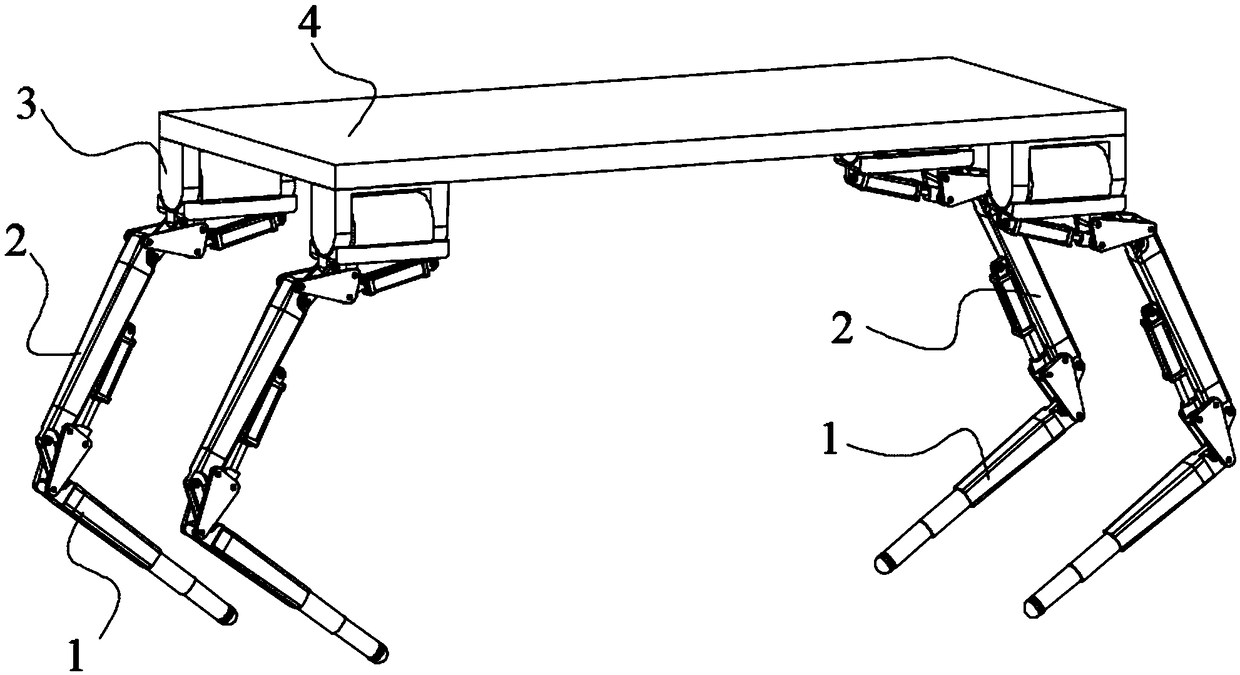

[0024] The whole quadruped robot is composed of calf 1, thigh 2, side swing 3 and robot platform 4. The side swing 3 is fixedly installed on the bottom of the four corners of the robot platform 4. The thigh 2 is installed on the side swing 3 through bending joints. The top of the calf 1 The leg joint structure is installed on the bottom of the thigh 2, and the bottom of the lower leg 1 walks on the ground. The gaits of walk, trot, pace, bound, and rotary gallop can be performed, and obstacles of a certain height or width can be crossed or stepped over.

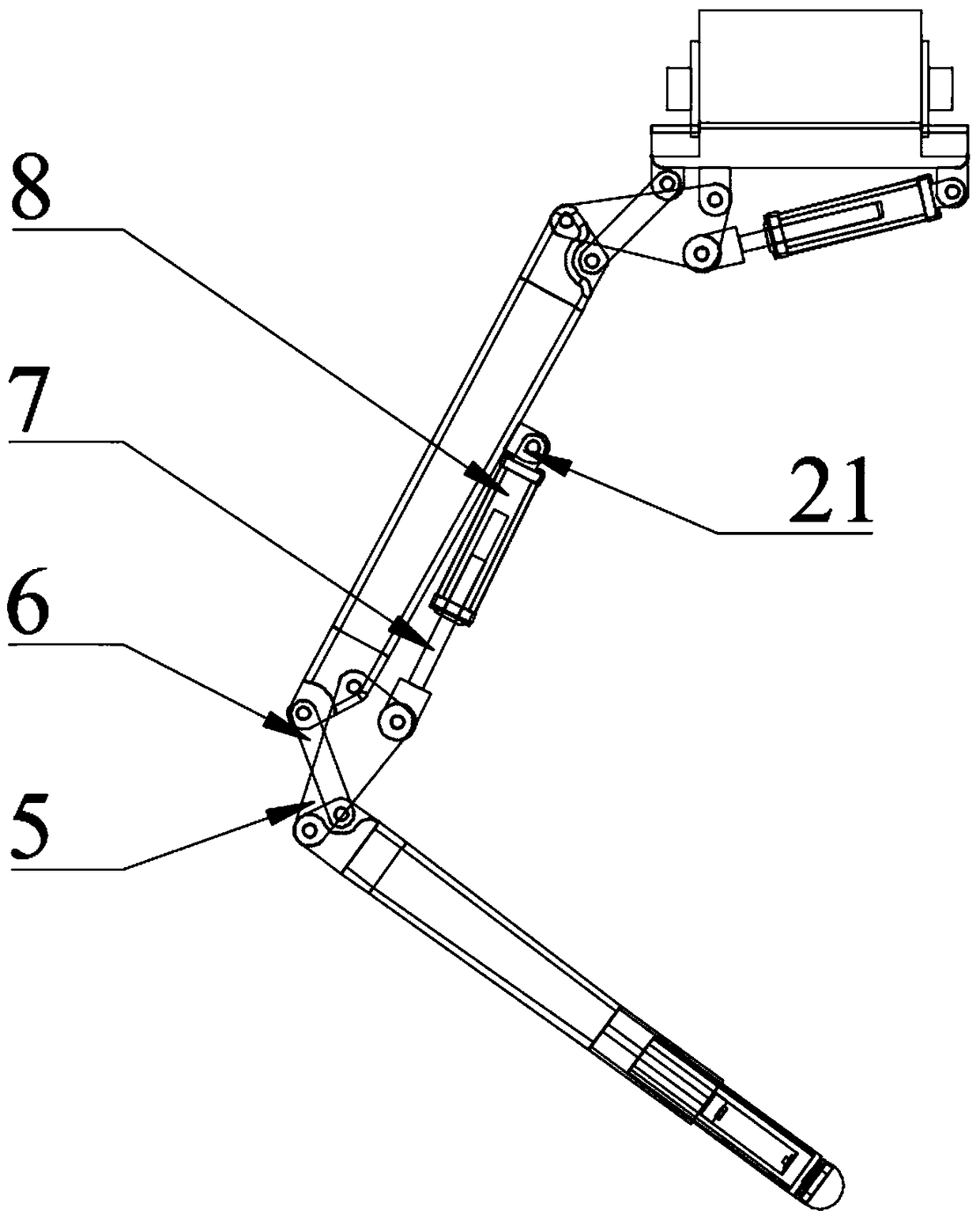

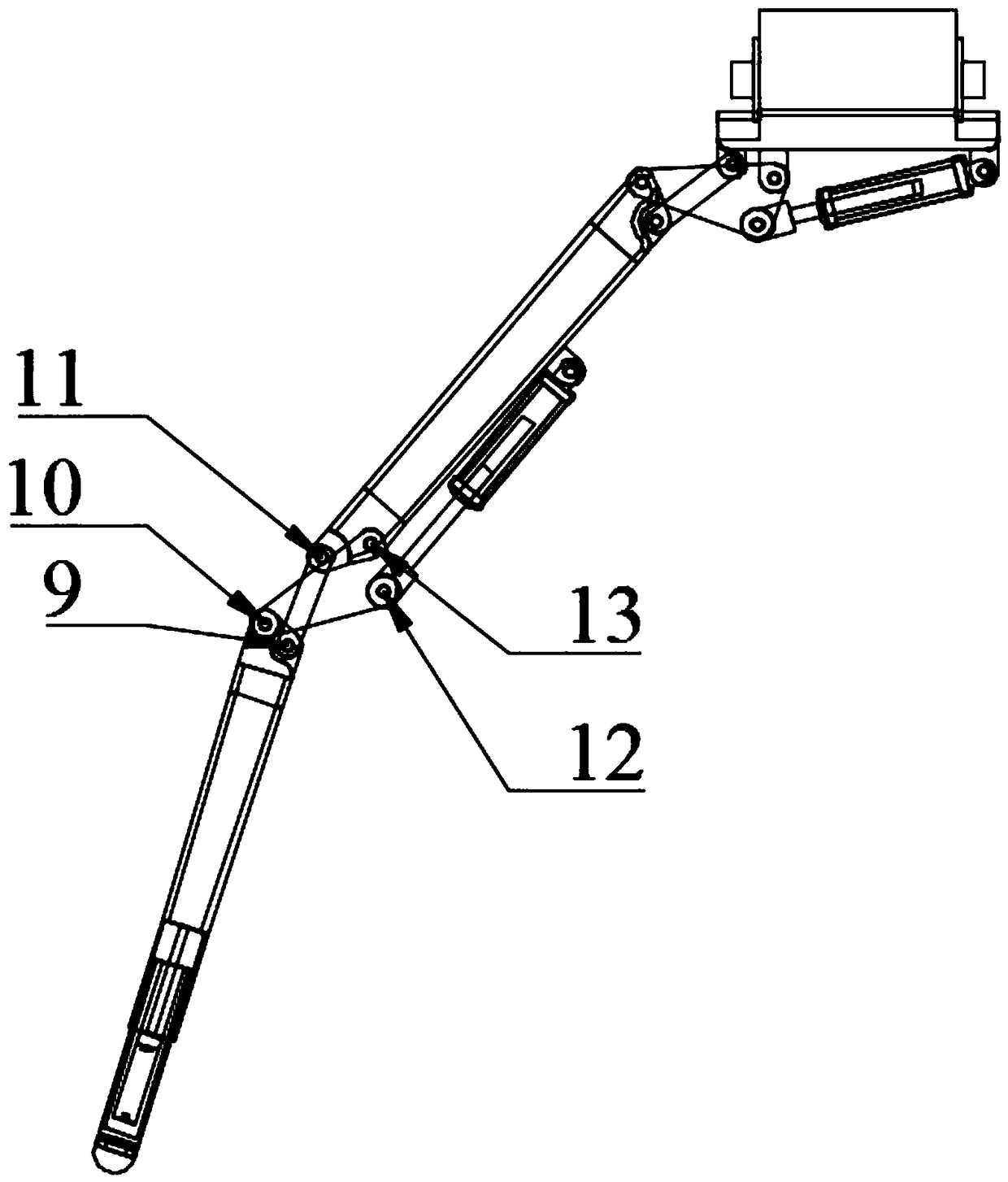

[0025] The leg joint structure includes a thigh 2 and a calf 1, and the thigh 2 and the calf 1 are connected through a large connecting rod 5, a small connecting rod 6 and a hydraulic cylinder 8, and one end of the large connecting rod 5 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com