Plastic part of automobile wiper and preparation method thereof

A technology of plastic parts and wipers, which is applied in vehicle cleaning, vehicle maintenance, household components, etc., and can solve problems such as affecting the driver's sight line, long connecting rods, easy aging and cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

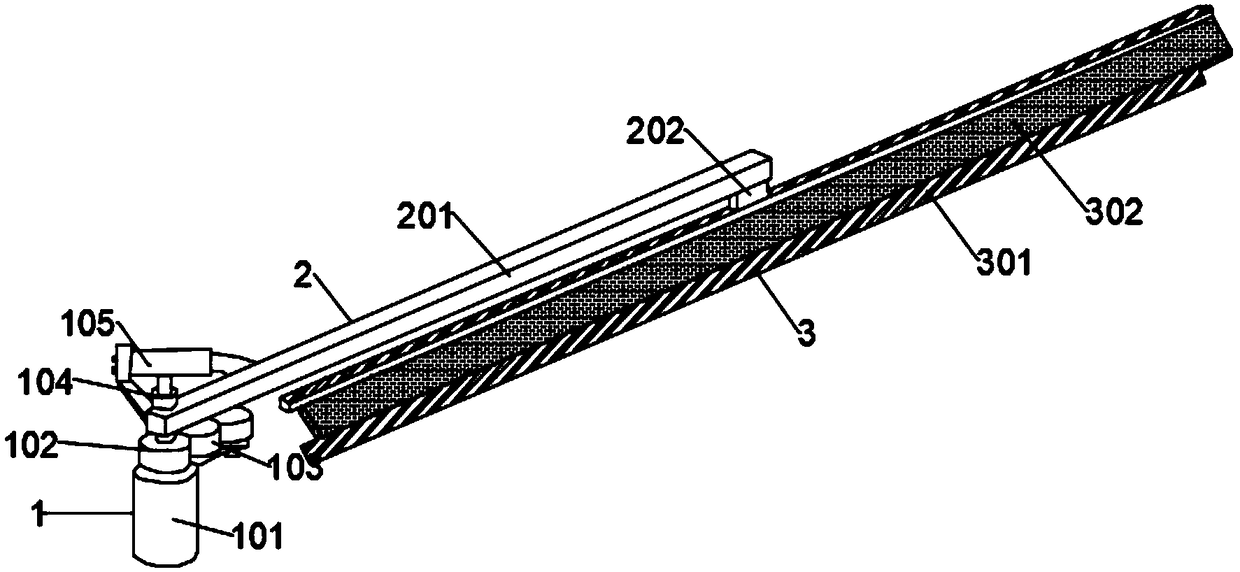

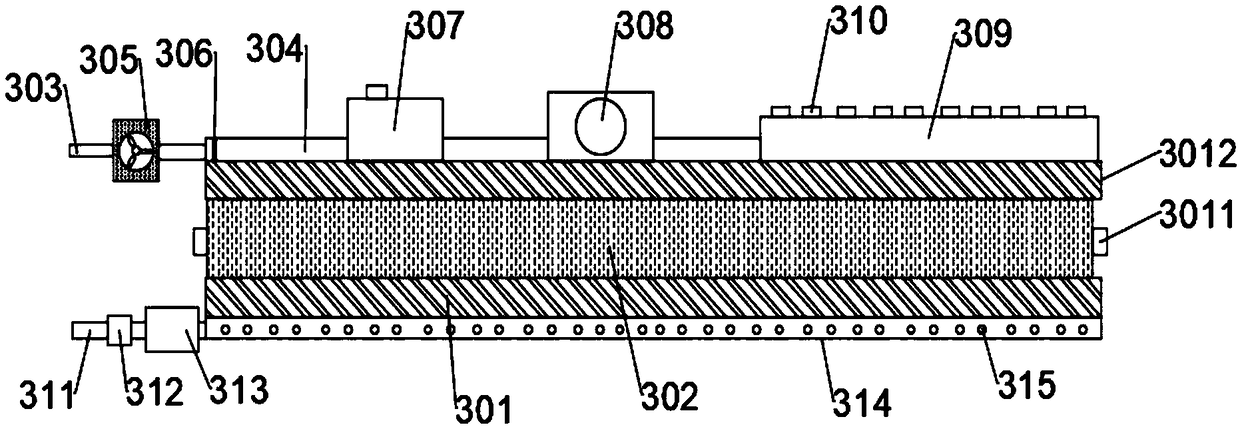

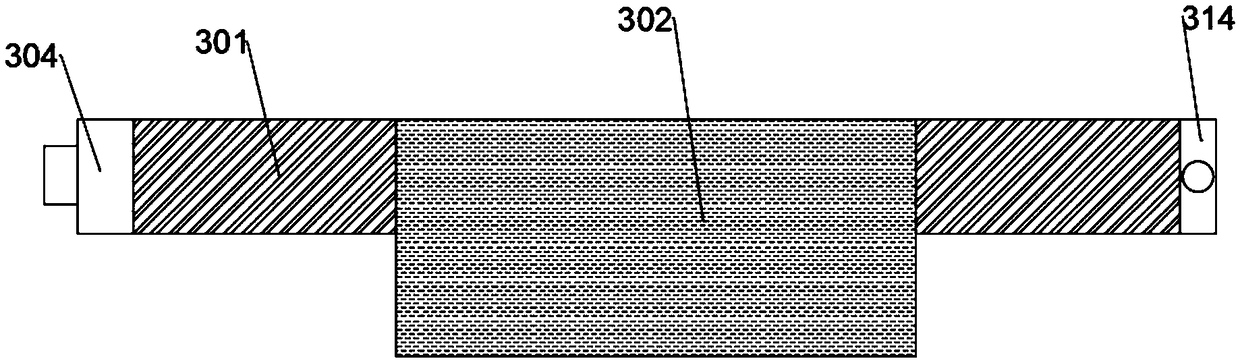

[0037] Such as figure 1 As shown, the present invention provides a plastic part of a car wiper including a power assembly 1, the power assembly 1 includes a driving motor 101, the upper end of the driving motor 101 is connected with a transmission gear 102, and the right side of the transmission gear 102 is provided with the transmission gear 102 Interlocking gears 103, the upper end of the transmission gear 102 is connected with a power rotating core 104, the power rotating core 104 is connected with a power transmission frame 2, and a transmission curved rod 105 is connected between the power rotating core 104 and the power transmission frame 2, The lower end of the power transmission frame 2 is provided with a wiper head 3 parallel to the power transmission frame 2. The wiper head 3 includes a wiper holder 301, a rubber brush body 302 is arranged in the wiper holder 301, and a gas The spray box 309 and the right side of the wiper holder 301 are provided with a liquid sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com