Manufacturing method of pressure-bearing equipment thick-wall seal head structure

A technology of pressure-bearing equipment and manufacturing methods, which is applied in the design and manufacture of thick-walled heads, can solve the problems of discontinuity, stress concentration, and irregularity of the outer surface of the head, and achieve the elimination of discontinuity of the outer surface and the reduction of ellipse degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

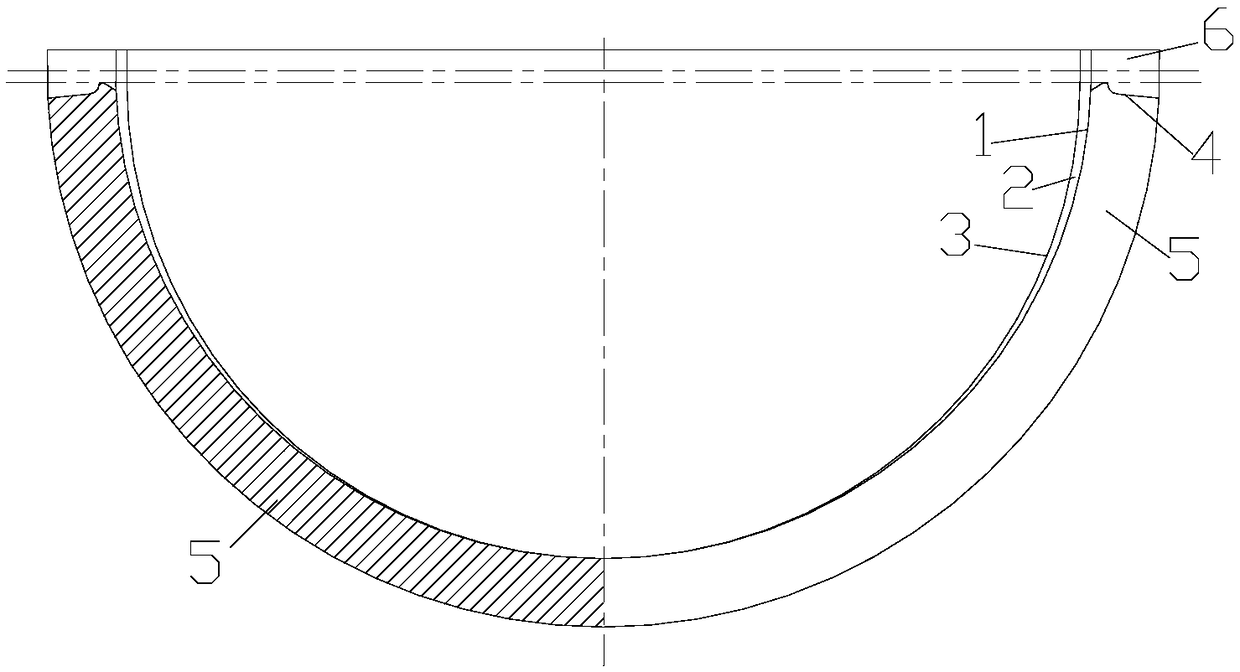

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

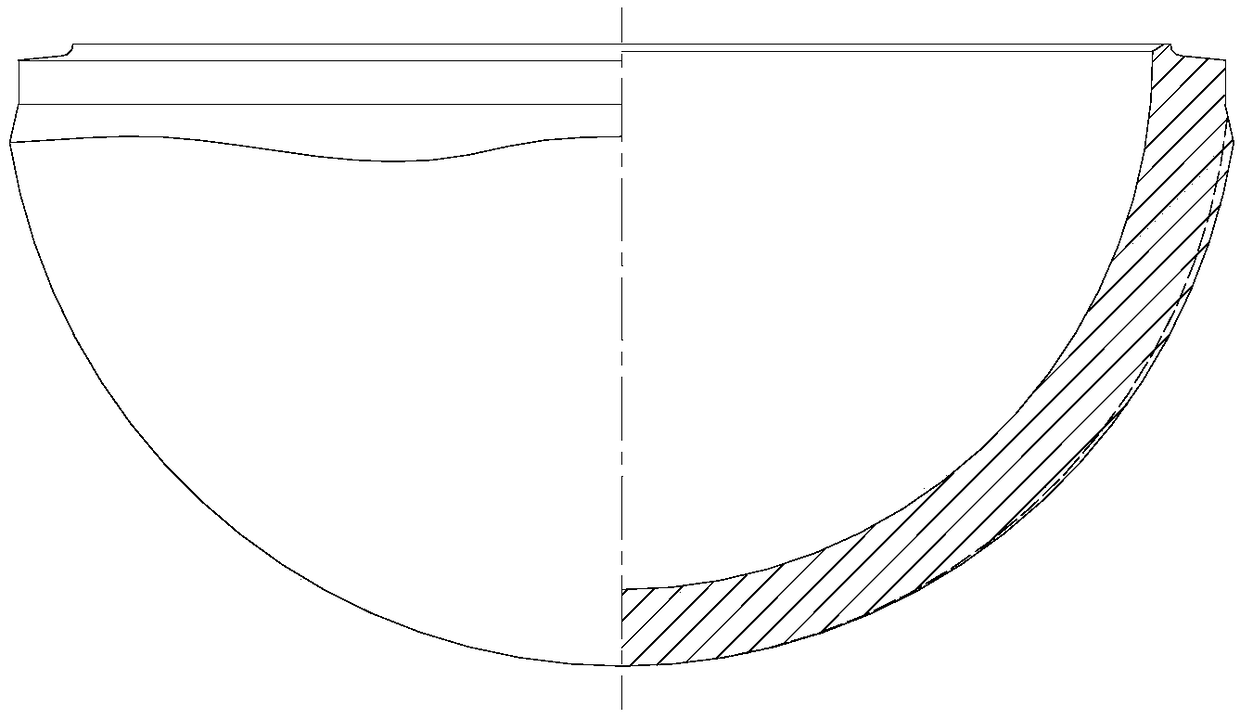

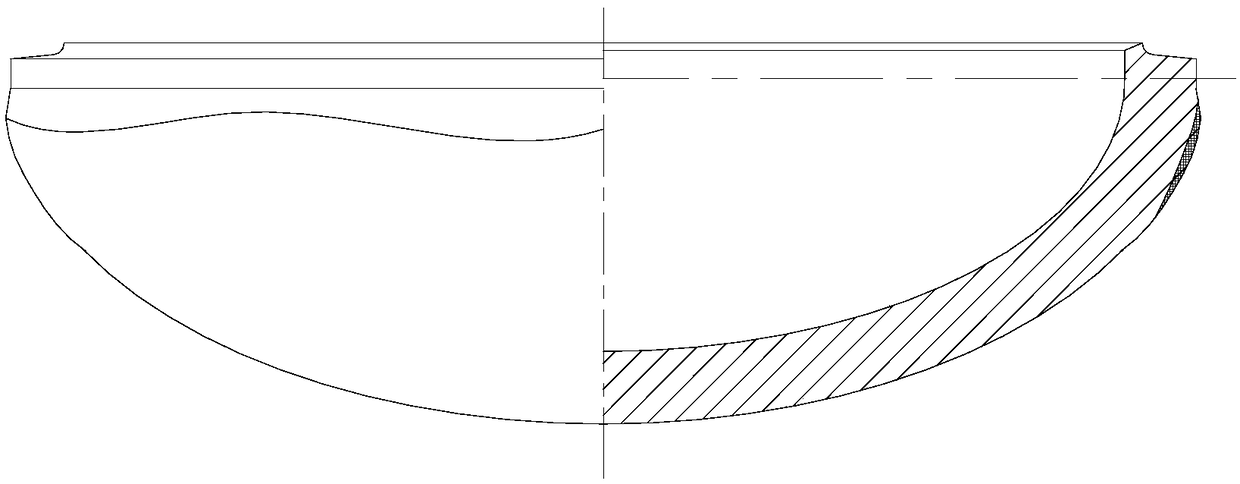

[0022] image 3 The design specification of a spherical head is SR1225×125, which is a non-standard head, and 125 mm is the minimum thickness. The design requires a thickness of 135 mm for the annular groove and an outer diameter of 2720 mm for the annular groove; the thickness of the steel plate blank is 145 mm. The minimum wall thickness of the head product is 130 mm; the maximum wall thickness of the head due to pressing and thickening is 160 mm, which is 25 mm greater than the required thickness of the circular joint groove.

[0023] In the past, a certain head was hot-pressed on the whole plate, pressed and thickened ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com