Resistance spot welding method and system suitable for steel and aluminum vehicle body mixed-line production

A technology of resistance spot welding and car body, applied in resistance welding equipment, resistance electrode holder, electrode maintenance, etc., can solve the problem of inability to achieve collinear production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

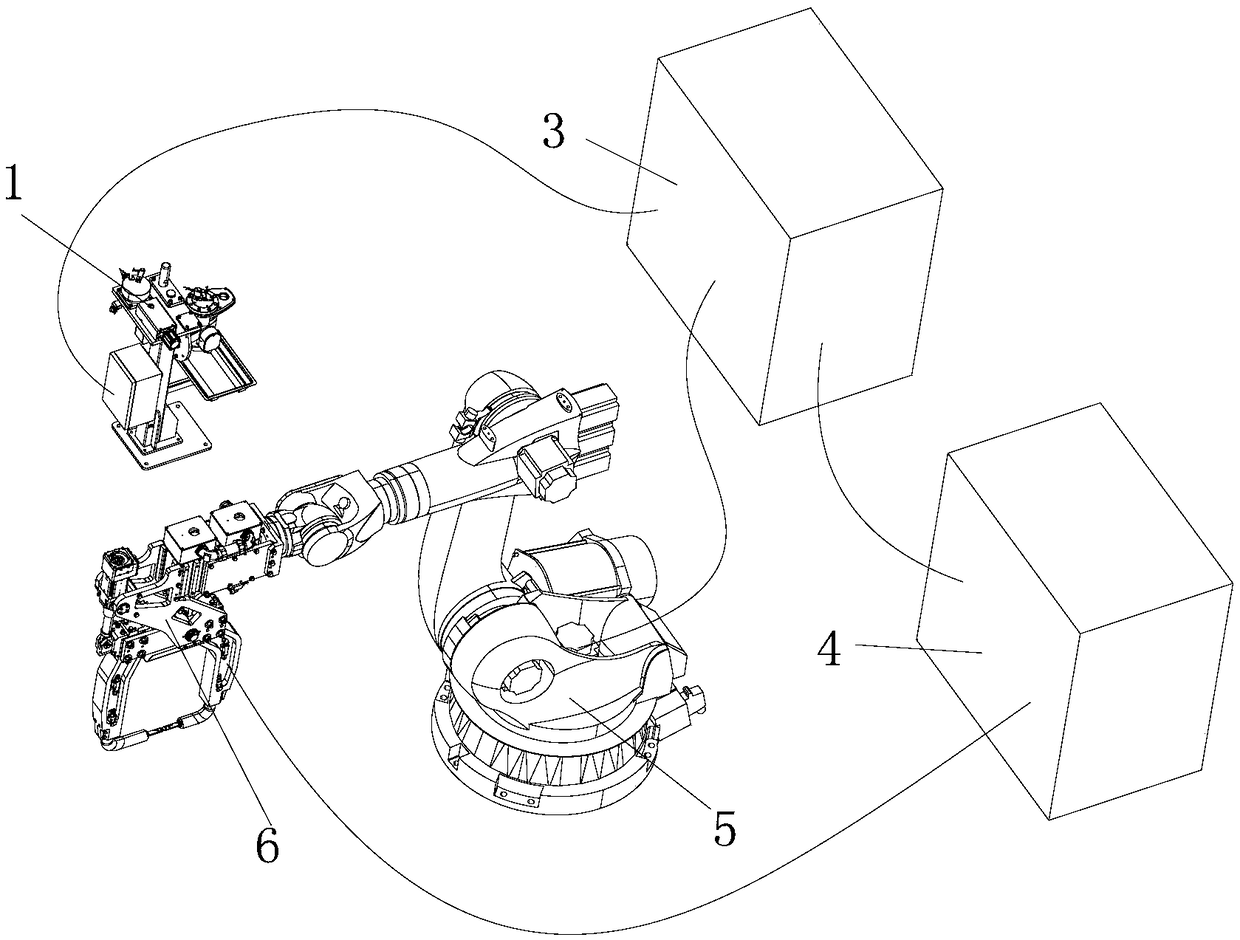

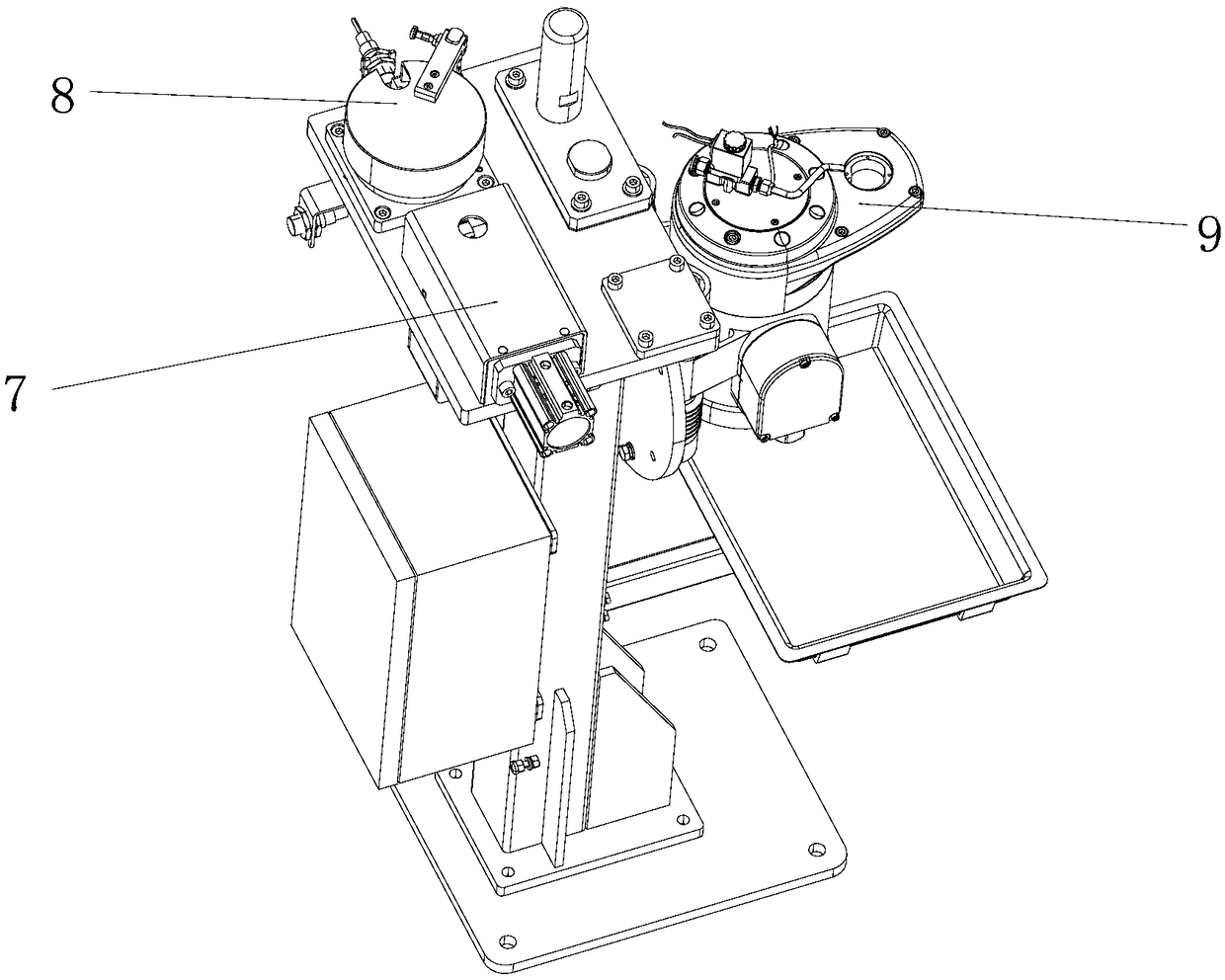

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

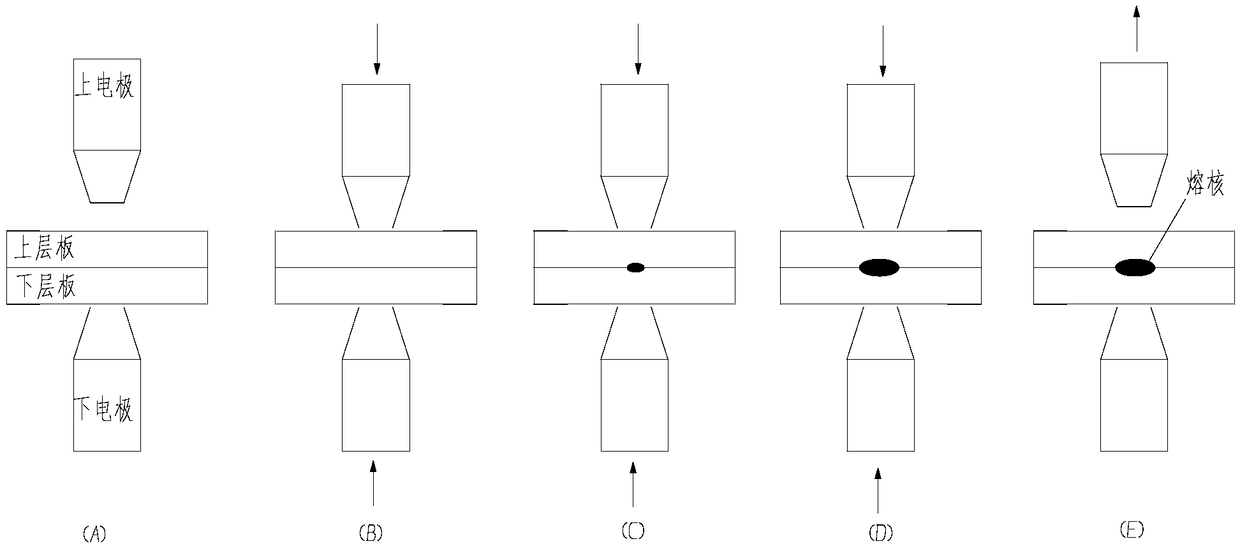

[0033] According to the robot resistance spot welding system of the present invention, the steel body and the aluminum body are welded at the same station to realize collinear production.

[0034] Considering the differences in physical and metallurgical properties of steel plates and aluminum alloys, the requirements for welding parameters are quite different, and different welding parameters are set for this purpose. Compared with steel, aluminum alloy spot welding requires higher welding current, shorter welding time (the welding current of aluminum alloy is about 3 times that of steel, and the welding time is about 1 / 3 of steel) and higher electrode pressure .

[0035] Considering the dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com