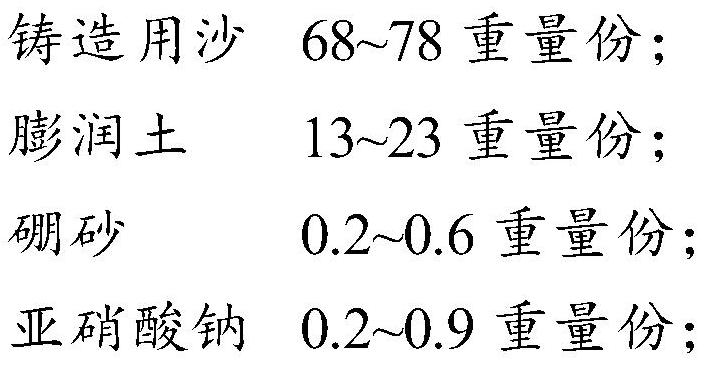

A kind of casting glass sand and preparation method thereof

A technology for casting glass and borax, which is used in casting and molding equipment, molds, manufacturing tools, etc., can solve problems such as large consumption, unsuitable for the scientific development of the foundry industry, and affecting workers' health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074]The present invention provides a method of casting a glass sand, including:

[0075]A) mix the casting with sand, bentonite to obtain the first mixture;

[0076]B) Mix the boron sand, water and the first mixture to obtain a cast glass sand.

[0077]The preparation method of cast glass sand provided by the present invention first mixed castings, bentonite, and bentonite to obtain a first mixture.

[0078]Specifically, casting is sand, and bentonite is mixed in the sand machine to mix 1 to 3 min, so that the sand and bentonite are mixed.

[0079]The present invention has a clear description of the above-described specific proportion of bentonite, and will not be described again herein. The mixing temperature can be at room temperature.

[0080]After mixing, the boron sand, water and the first mixture were mixed to obtain a cast glass sand.

[0081]The present invention is not limited to the specific manner of the mixing, and the mixing time is 2 to 8 min.

[0082]This step is:

[0083]The boron sand, nite...

Embodiment 1

[0092]Casting was 80 mesh for 60kg sand and 200 destination 10kg bentonite to mix the sand mold mixture for 2 minutes, so that the sand and bentonite were mixed, and then 3 kg of water and 300 mesh 0.1 kg boron sand, 0.1 kg nitrogen thoroughly mixed The glass sand of the present invention has a mixed time of 3 minutes.

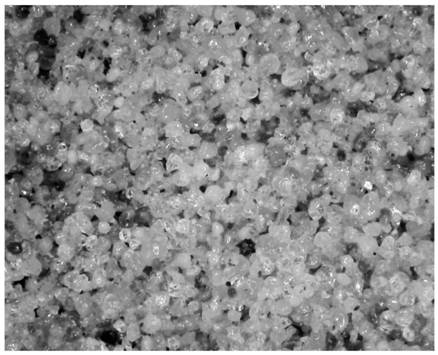

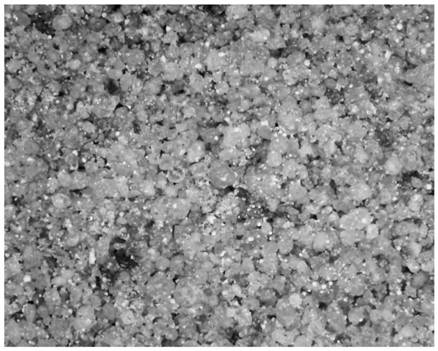

[0093]figure 1 A glass sand map prepared by the present invention is added to the present invention;figure 2For the same example but not added to the glass sand map prepared by the boron;figure 1 The flash of flash is the effect of re-solidifying the surface of the sand and the gap in the surface of the sand and the gap.figure 2There is no effect of solidification of liquid glass, and there are more sand clearances.

Embodiment 2

[0095]The casting of 70kg sand and 200 mesh of 80 mesh were added to the sand mixing machine for 3 minutes, and the sand and bentonite were thoroughly mixed, and then 4 kg of water and 300 mesh 0.2kg boron sand, 0.2kg nitrogen thoroughly mixed The glass sand of the present invention is obtained, and the mixing time is 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com