Visible-light response MoS2/GO/g-C3N4 ternary composite photocatalytic material and preparation method thereof

A photocatalytic material and ternary composite technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low photogenerated electron-hole separation efficiency and binary system catalytic efficiency No high-level problems, to achieve the effect of improving photocatalytic performance, improving electron conduction ability, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

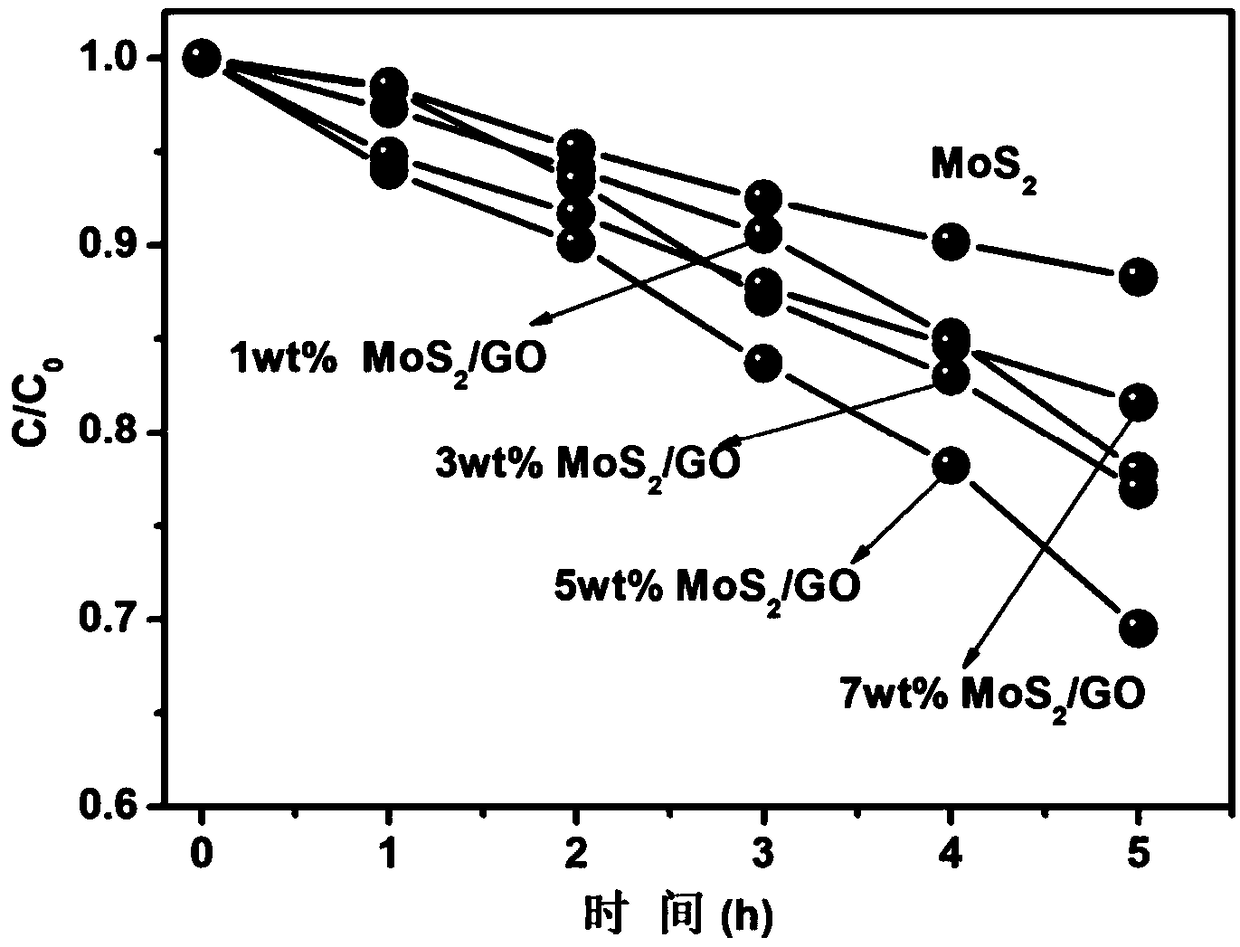

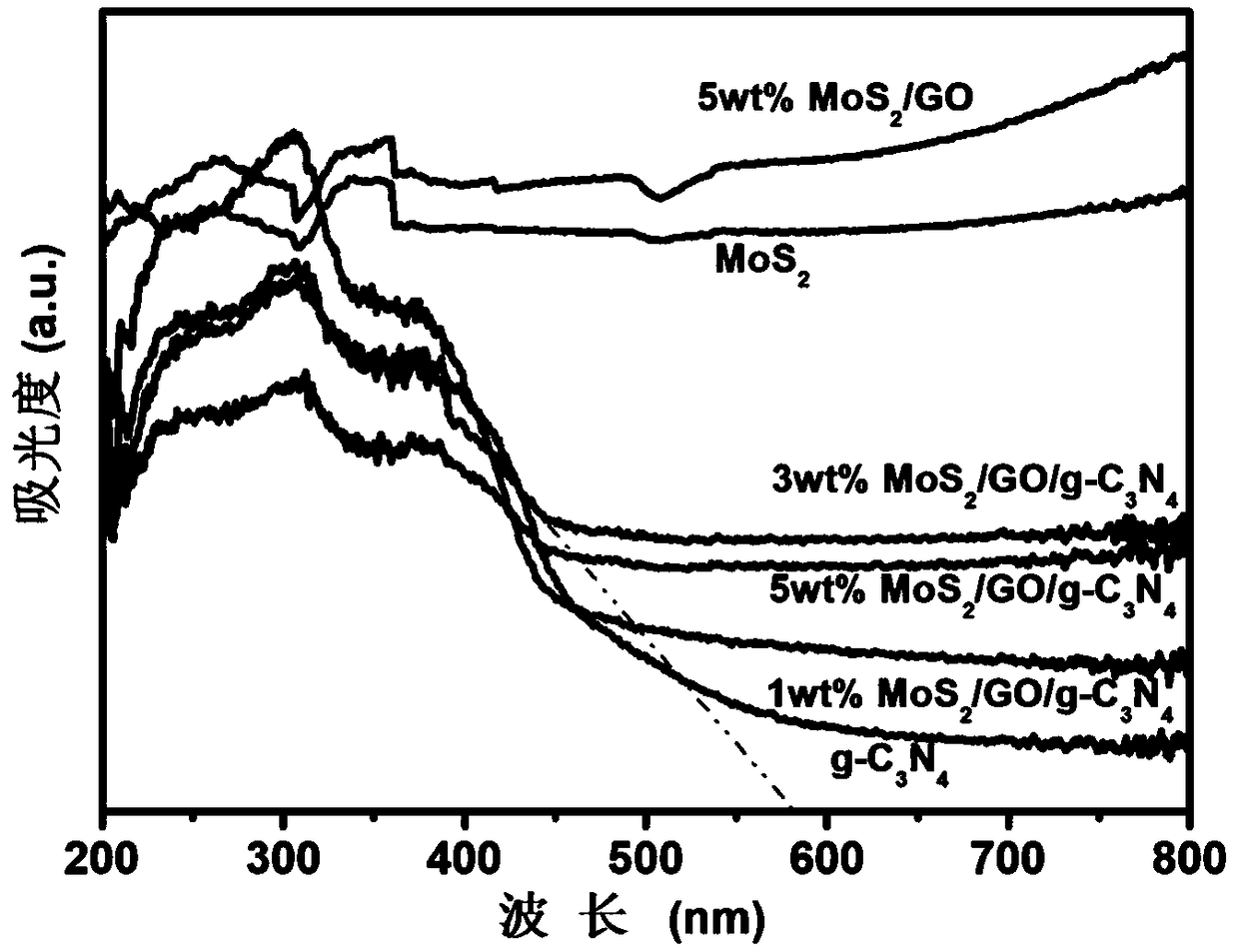

[0030] The present invention confirms that MoS 2 Optimum Catalyst Ratio of / GO Binary Composite Photocatalytic Materials to Synthesize MoS 2 / GO / g -C 3 N 4 Ternary composite photocatalytic materials. With 5wt%MoS 2 / GO binary ternary composite photocatalytic material preparation as an example:

[0031] 0.1439g of MoO 3 Add 0.2429g of KSCN to 10mL of deionized water, stir and ultrasonically disperse for 30min to obtain a mixed solution; disperse 0.005g of GO in 10mL of ethylene glycol, disperse evenly, add to the above mixed solution, and continue ultrasonically dispersing for 30min , into a 25mL reactor, 180 o C oven constant temperature 24h. After cooling to room temperature, wash with ethanol and deionized water three times respectively, and centrifugally dry to obtain MoS with 5 wt% GO. 2 / GO binary composite photocatalytic materials.

[0032] Wherein, the present invention does not specifically limit the specific source of the GO, which can be commercially availab...

Embodiment 2

[0035] 1wt%MoS 2 / GO / g -C 3 N 4 Preparation of Ternary Composite Photocatalytic Materials

[0036] The 5wt%MoS prepared in 0.001g embodiment 1 2 / GO and 0.099g of g-C 3 N 4 Add 20mL of ethylene glycol, stir and ultrasonically disperse for 30min each, then put it into a kettle and put it in an oven at 180°C for 24h at a constant temperature. Get MoS 2 MoS with 1wt% / GO ratio 2 / GO / g -C 3 N 4 ternary composite photocatalytic materials.

[0037] Wherein, the present invention is to described g-C 3 N 4 The specific source of is not particularly limited, and it can be commercially available or prepared by solid-state reaction, solvothermal or thermal polymerization. Preferably, the g-C 3 N4 adopts the following preparation method, specifically:

[0038] 6g dicyandiamide is placed in the tube furnace, under nitrogen atmosphere, with 5 o C / min from room temperature to 350°C, keep it for 120min, and then increase the temperature by 5 o C / min raise the temperature to 600...

Embodiment 3

[0040] 3wt%MoS 2 / GO / g -C 3 N 4 Preparation of Ternary Composite Photocatalytic Materials

[0041] The 5wt%MoS prepared in 0.003g embodiment 2 2 / GO and 0.097 g of g-C 3 N 4 Add 20mL of ethylene glycol, stir and ultrasonically disperse for 30min each, then put it into a kettle and put it in an oven at 180°C for 24h at a constant temperature. Get MoS 2 MoS with 3wt% / GO 2 / GO / g -C 3 N 4 ternary composite photocatalytic materials.

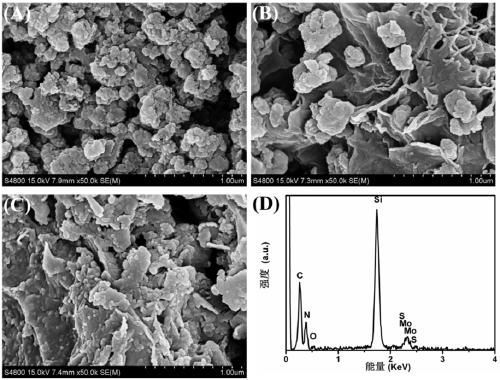

[0042] attached figure 2 for MoS 2 , 5wt%MoS 2 / GO, 3wt%MoS 2 / GO / g -C 3 N 4 SEM images of and 3wt%MoS 2 / GO / g -C 3 N 4 Electron dispersion energy spectrum of ; in the figure (A) is MoS 2 SEM image of , (B) is 5wt%MoS 2 SEM image of / GO, (C) is 3wt%MoS 2 / GO / g -C 3 N 4 scanning electron microscope image. As shown in the figure, 3wt%MoS 2 / GO / g -C 3 N 4 Medium MoS 2 It has a smaller nanoscale and is uniformly dispersed on GO, while GO is combined with the carrier material g-C 3 N 4 Under the action of π-π conjugation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com