Four-section dental implant

A dental implant, a four-stage technology, applied in the field of stomatology, can solve the problems of difficult thread fit, poor thread mechanical properties, poor mechanical properties, etc., to reduce replacement costs, ensure connection strength, and improve processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

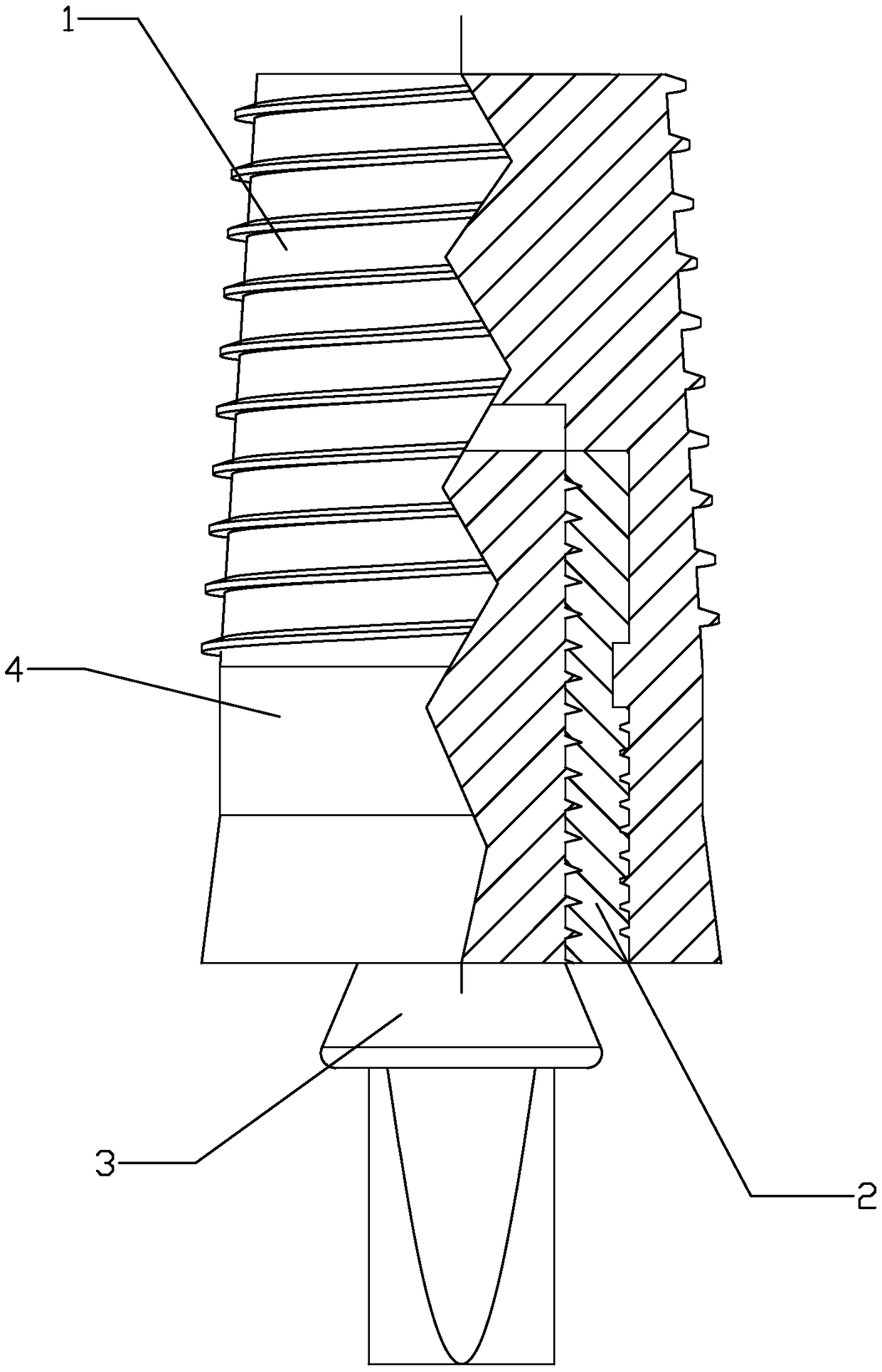

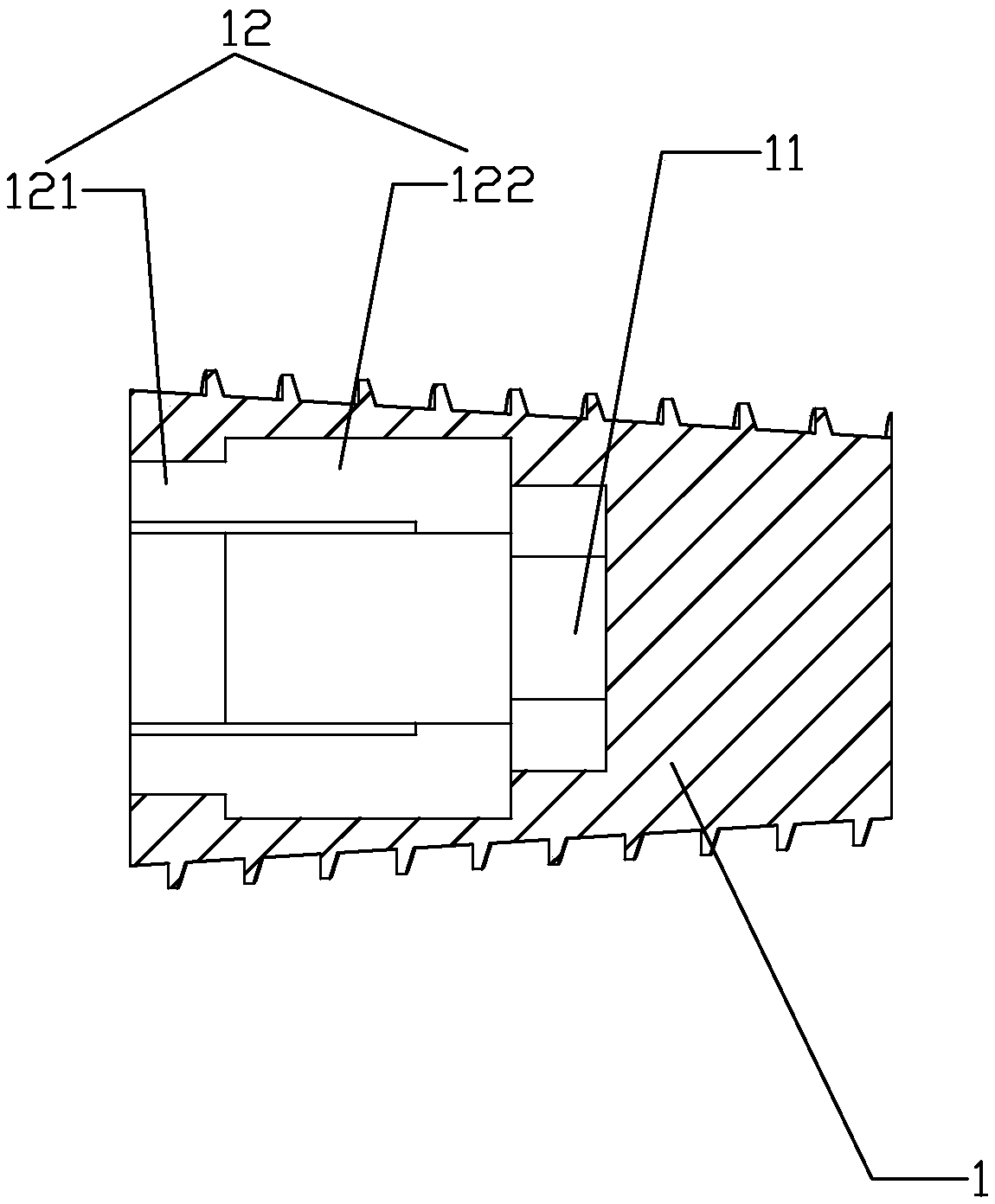

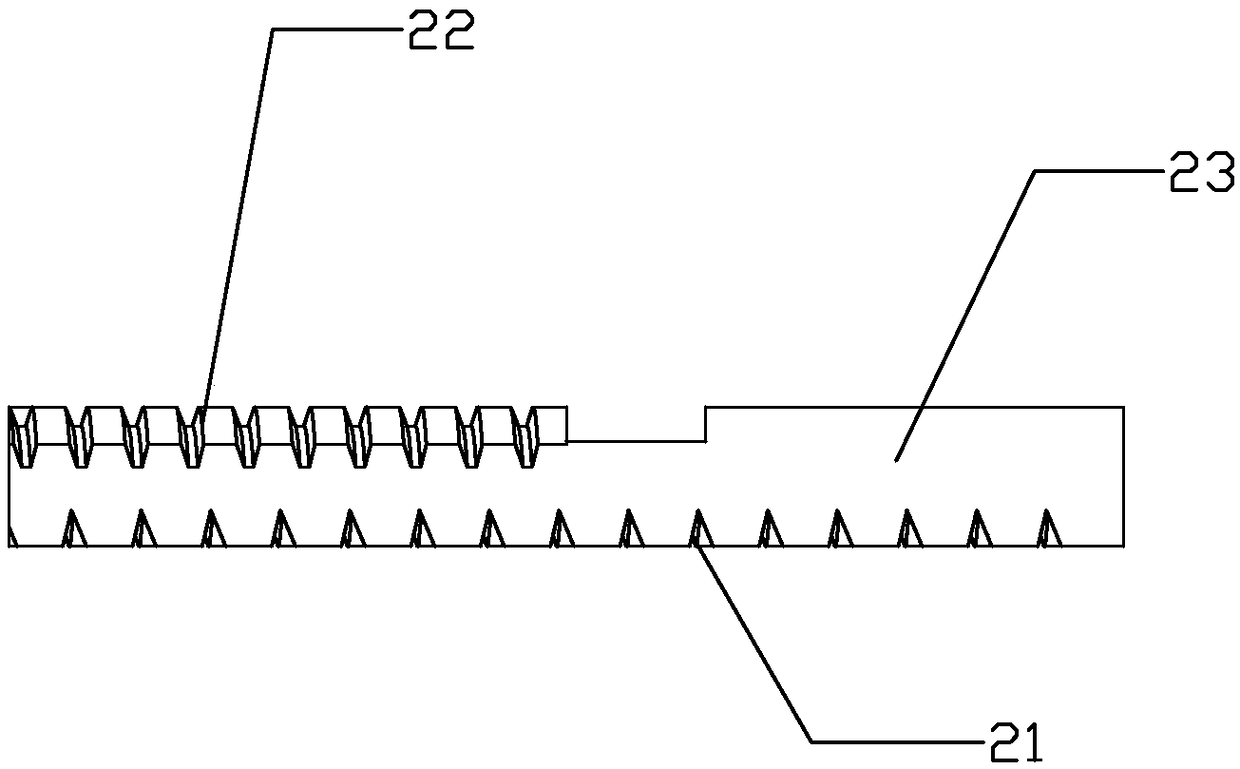

[0025] refer to Figure 1 to Figure 6 , a four-stage dental implant, the dental implant includes a bone graft part 1, a connecting part, an abutment part 3 and a gingival part; the bone graft part 1 is a rotary structure, and the bone graft part 1 There is a connection cavity inside, a groove 11 is provided at the bottom of the connection cavity, and at least two limiting grooves 12 are provided on the inner wall of the connection cavity; the connection part is composed of several connection blocks 2, The number of connecting blocks 2 is the same as the number of limiting grooves 12, the inner side of the connecting block 2 is provided with the abutment connecting threaded section 21, and the outer side of the connecting block 2 is provided with a transgingival connecting threaded section 22 and a limiting protrusion 23, the limiting protrusion 23 is arranged under the gingival connection thread section 22, the limiting protrusion 23 is matched with the limiting groove 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com