Hollow manganese-doped cobalt nickel oxide coated nitrogen-doped carbon nanocomposites and preparation method thereof

A nanocomposite material, nitrogen-doped carbon technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of low durability, high cost, unfavorable large-scale commercial application, etc., Achieve the effect of uniform structure and morphology, avoid agglomeration, simple and efficient modification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A nitrogen-doped carbon nano-composite material coated with hollow manganese-doped cobalt-nickel oxide, comprising a hollow nitrogen-doped carbon material, the hollow nitrogen-doped carbon material being coated with manganese-doped cobalt-nickel oxide. The hollow nitrogen-doped carbon material has a hollow polyhedral structure.

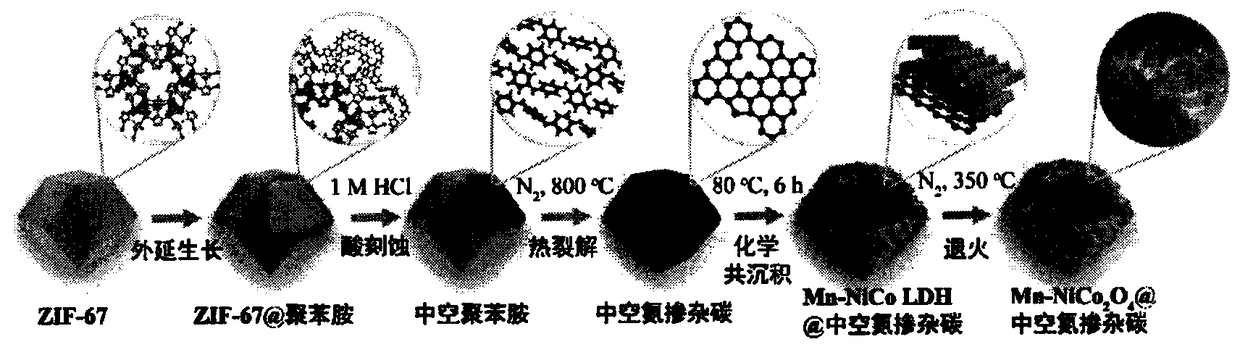

[0048] Such as figure 1 As shown, the preparation method of the nitrogen-doped carbon nanocomposite coated with hollow manganese-doped cobalt-nickel oxide is as follows:

[0049] Step 1: Synthesis of hollow nitrogen-doped carbon:

[0050] A) A layer of polyaniline is coated on the surface of ZIF-67 by solution polymerization to obtain ZIF-67@polyaniline composite material: ultrasonically disperse ZIF-67 powder in 100mL of water, and ultrasonically treat it for 20min to obtain a dispersion, ZIF The concentration of -67 was 1 mg / mL. Then 20 μL of aniline (Sigma-Aldrich) monomer was added into the above dispersion liquid to make it uniformly di...

Embodiment 2

[0061] Similar to the nitrogen-doped carbon nanocomposite material coated with hollow manganese-doped cobalt-nickel oxide in Example 1, the difference is that the amount of manganese nitrate added in Example 1 is reduced to 6×10 -5 mol, the obtained product is labeled as hollow manganese-doped cobalt-nickel oxide-coated nitrogen-doped carbon nanocomposite-1.

Embodiment 3

[0063] Similar to the nitrogen-doped carbon nanocomposite material coated with hollow manganese-doped cobalt-nickel oxide in Example 1, the difference is that the amount of manganese nitrate added in Example 1 is increased to 1×10 -4 mol, the obtained product is labeled as hollow manganese-doped cobalt-nickel oxide-coated nitrogen-doped carbon nanocomposite-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com