Fabricated door window and mounting method thereof

A prefabricated, door and window technology, applied in the field of architectural decoration, can solve the problems of short construction period of prefabricated buildings, easily affected installation quality waterproof and sealing, and no external scaffolding, etc., to improve the construction environment, shorten the construction period, and improve the integrity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

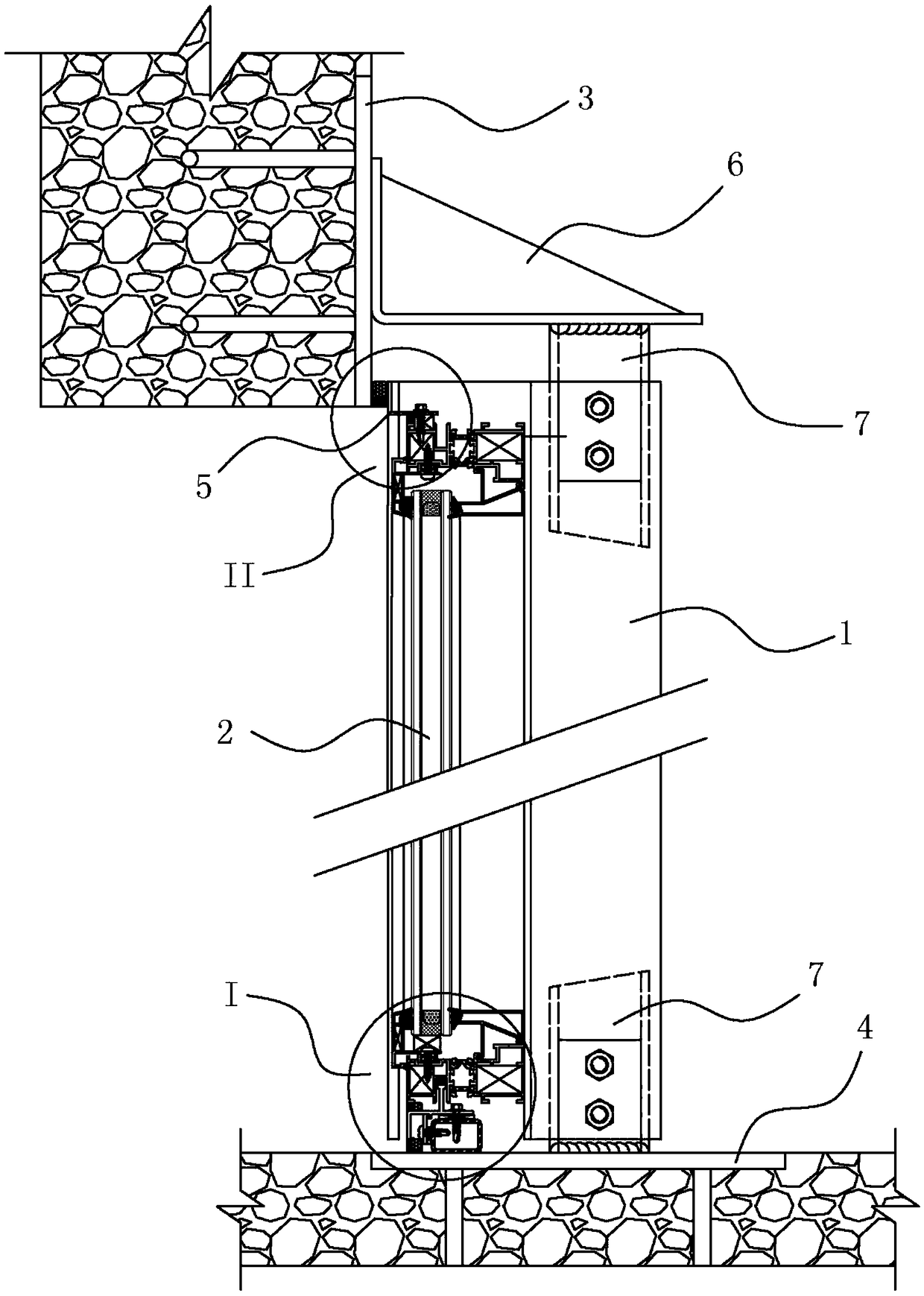

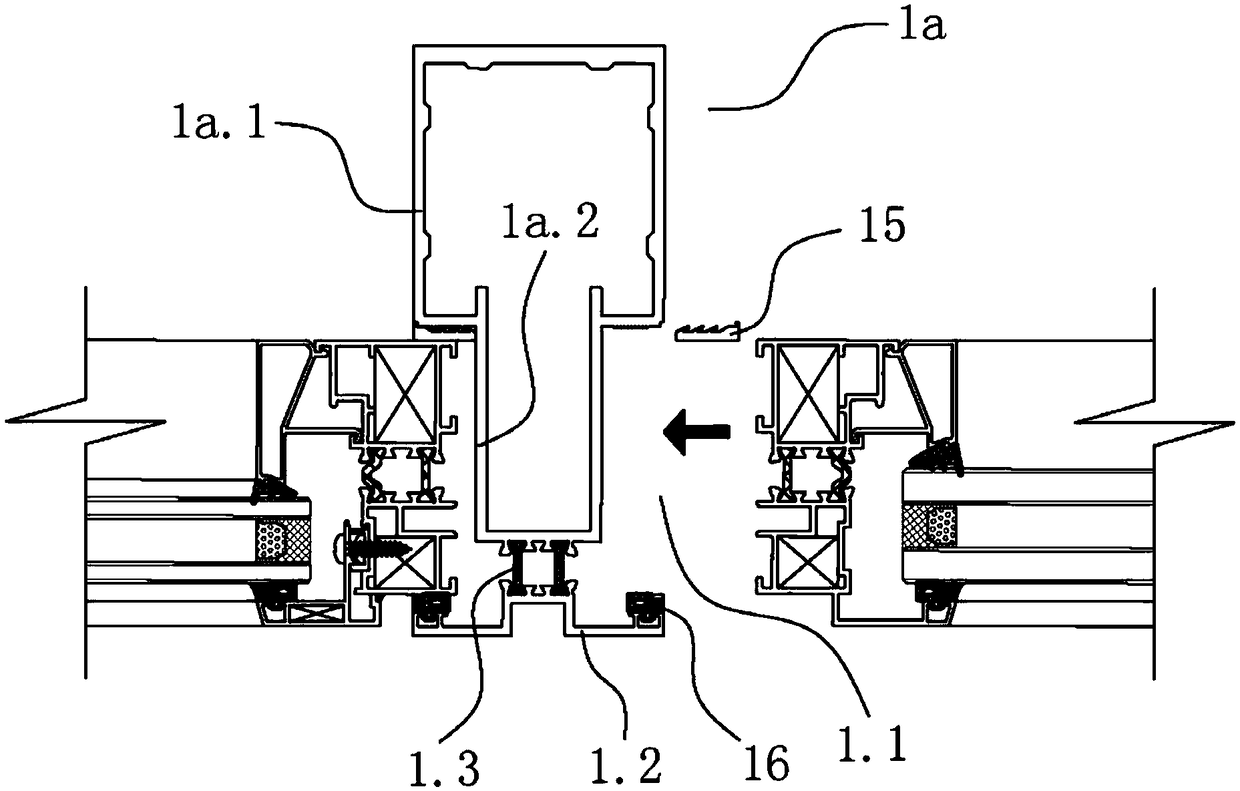

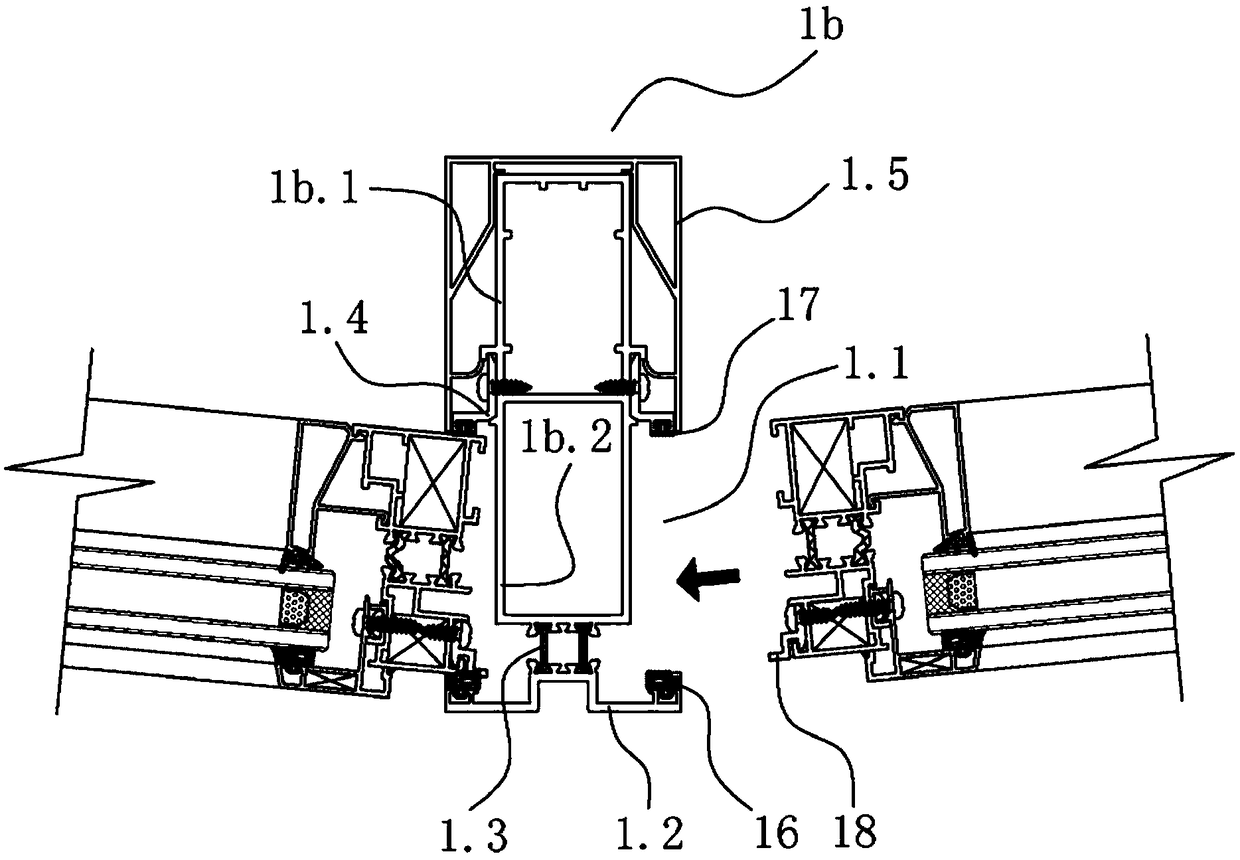

[0044] Such as Figure 1 to Figure 3As shown, the embodiment of the present invention provides an assembled door and window, including embedded parts, column 1 and unit window 2; the embedded parts are preferably steel or aluminum, which are divided into top embedded parts 3 and The bottom embedded part 4, the top embedded part 3 are used to embed the wall at the top of the window, and the bottom embedded part 4 is used to embed on the window sill surface; the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com