Preparation method of cracking carbon nanotube strengthened copper-based composite material

A copper-based composite material, carbon nanotube technology, applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of carbon nanotubes that are difficult to disperse uniformly, difficult to bond at the interface of the matrix, and low in reinforcement effect. Good comprehensive mechanical properties, improved load transfer efficiency, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of cracked carbon nanotube reinforced copper-based composite material, the specific steps are as follows:

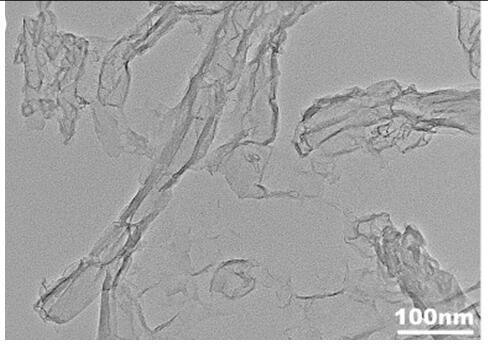

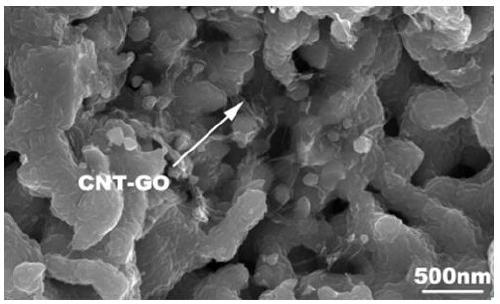

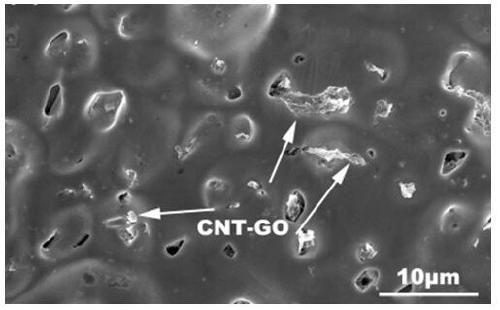

[0036] (1) Cracking of carbon nanotubes:

[0037] Add carbon nanotube CNTs into concentrated sulfuric acid according to the mass volume ratio of CNTs to concentrated sulfuric acid g:mL of 1:5 and stir for 1 hour. At the same time, add concentrated phosphoric acid and potassium permanganate and stir to obtain a suspension. Sulfuric acid: add concentrated phosphoric acid at a volume ratio of 1:8, add potassium permanganate at a ratio of 1:5 between CNTs and potassium permanganate, then put the suspension in a water bath and heat it to 70°C for a holding time After cooling to room temperature for 5 hours, under ice bath conditions, according to the volume ratio of the suspension to the deionized water containing hydrogen peroxide as 1:5, pour the deionized water containing hydrogen peroxide into the deionized water containing hydrogen peroxide T...

Embodiment 2

[0048] A preparation method of cracked carbon nanotube reinforced copper-based composite material, the specific steps are as follows:

[0049] (1) Cracking of carbon nanotubes:

[0050] Add carbon nanotube CNTs into concentrated sulfuric acid according to the mass volume ratio of CNTs to concentrated sulfuric acid g:mL of 1:6 and stir for 1.5 hours. At the same time, add concentrated phosphoric acid and potassium permanganate and stir to obtain a suspension. Sulfuric acid: add concentrated phosphoric acid at a volume ratio of 1:8.5, add potassium permanganate at a ratio of 1:7 between CNTs and potassium permanganate, then put the suspension in a water bath and heat it to 75°C for a holding time After cooling to room temperature for 3 hours, under ice bath conditions, according to the volume ratio of the suspension to the deionized water containing hydrogen peroxide as 1:5, pour the deionized water containing hydrogen peroxide into the deionized water containing hydrogen peroxi...

Embodiment 3

[0060] A preparation method of cracked carbon nanotube reinforced copper-based composite material, the specific steps are as follows:

[0061] (1) Cracking of carbon nanotubes:

[0062] Add carbon nanotube CNTs into concentrated sulfuric acid according to the mass volume ratio of CNTs to concentrated sulfuric acid g:mL of 1:8 and stir for 2 hours. At the same time, add concentrated phosphoric acid and potassium permanganate and stir to obtain a suspension. Sulfuric acid: add concentrated phosphoric acid at a volume ratio of 1:9, add potassium permanganate at a mass ratio of CNTs to potassium permanganate at a ratio of 1:8, then put the suspension in a water bath and heat it to 80°C for a holding time After cooling to room temperature for 2 hours, under ice bath conditions, according to the volume ratio of the suspension to the deionized water containing hydrogen peroxide as 1:5, pour the deionized water containing hydrogen peroxide into the deionized water containing hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com