Method for preparing smokeless fireworks bright beads

A technology of bright beads and fireworks, applied in the direction of offensive equipment, explosives processing equipment, explosives, etc., can solve the problems that smokeless pollen cannot be effectively matched and the use effect is not ideal, and achieve obvious industrial promotion and application value, good viewing effect, and smoke Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

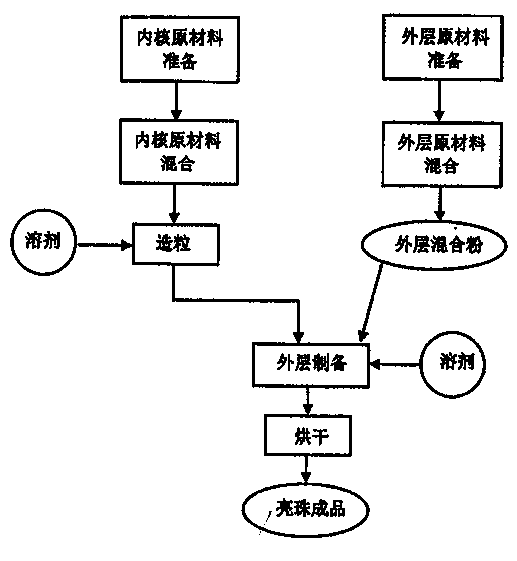

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in more detail below with reference to the drawings and examples, but the present invention is not limited to these examples.

[0037] A method for preparing bright beads of smokeless pyrotechnic agent, including four kinds of red, green, purple and yellow, all composed of inner core and outer layer, in the shape of beads, wherein the mass ratio of inner core composition is respectively:

[0038] Red: KMnO 4 55%, SrCO 3 24%, epoxy chips 17%, dextrin 4%;

[0039] Green: Ba(NO 3 )2 50%; magnesium powder 10%, aluminum powder 10%, resin 7%, rare earth 7%, KCIO4 15%, epoxy chips 1%;

[0040] Purple: CuO 20%, KCIO 4 40%, PVC 10%, phenolic resin 10%, magnesium industry cluster 8%, aluminum powder 8%;

[0041] Yellow: with substances containing sodium salts Materials:

[0042] The outer layer is a flame delay layer, designed according to zero oxygen balance, the dosage accounts for 15-45% of the weight of the bright beads, and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com