Preparation method of high-tolerance nanophase graphene composite ceramic

A graphene composite and nanophase technology, applied in the field of two-dimensional material composite, can solve the problems of limited functional materials, device performance degradation, easy to be physically damaged, etc., and achieve strong chemical bonding force, large structural strain, and high tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

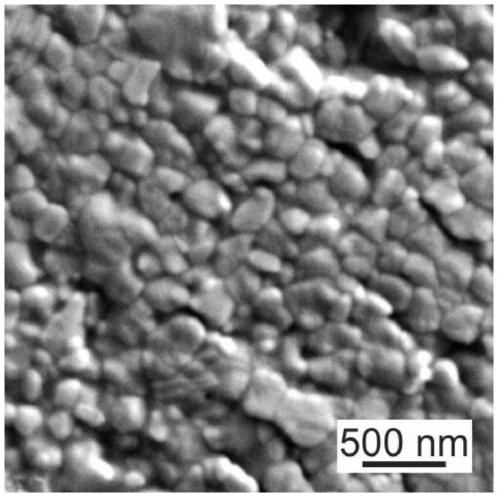

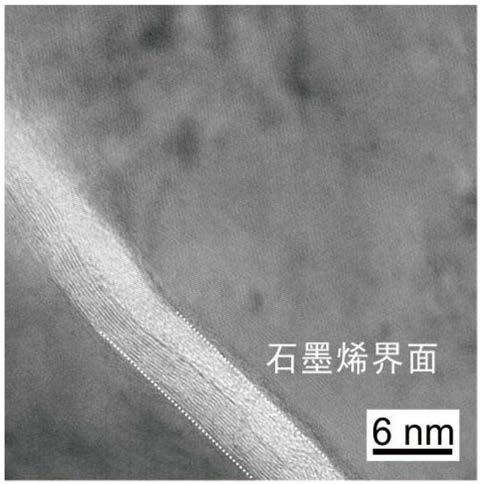

[0039] Embodiment 1, preparation nano-phase graphene composite Al2O3 ceramics

[0040] Wash aluminum oxide nanocrystals with a purity of 99.99% and a crystal particle size of 30-50 nm three times with deionized water and then dry them. Take 0.8 g of the dried aluminum oxide and place it in pure water for ultrasonication for 20 minutes. , after cooling, ultrasonication was repeated 15 times to prepare a suspension of aluminum oxide.

[0041] Put the metal nickel powder with a purity of 99%, a crystal particle size of 50nm, and a mass of 0.2g into ethanol for ultrasonication and stirring for 20 minutes, then ultrasonication after cooling, and repeat 6 times to prepare a metallic nickel dispersion; Mixed with aluminum oxide suspension.

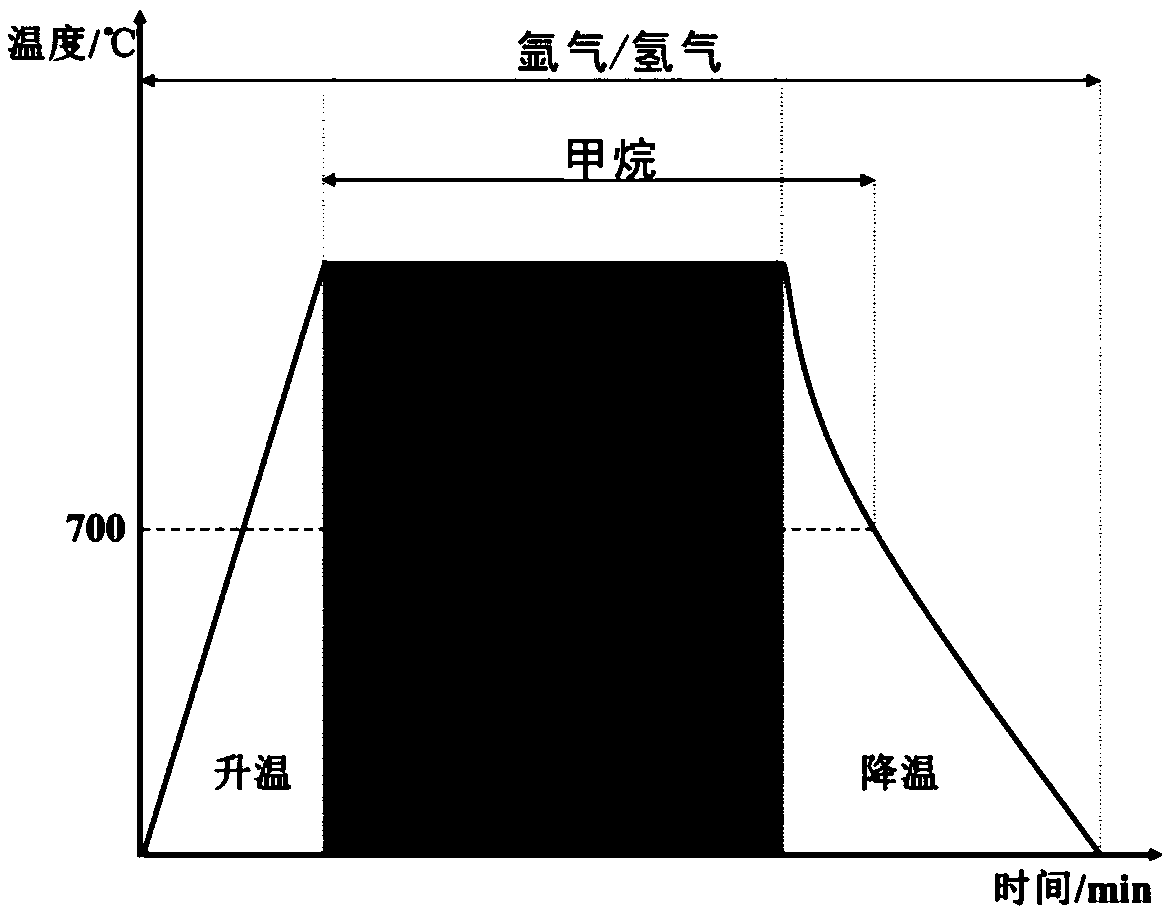

[0042] Drying is carried out by heating while stirring. The mixed liquid was placed on the hot stage, the temperature of the hot stage was 130° C., and the two kinds of nanocrystals were fully mixed by heating while stirring. A mixed nanocryst...

Embodiment 2

[0051] Embodiment 2, preparation nano-phase graphene composite silicon nitride ceramics

[0052] Wash silicon nitride nanocrystals with a purity of 99.99% and a crystal particle size of 30-50 nm three times with deionized water and then dry them. Take 0.8 g of the dried silicon nitride and place it in pure water for ultrasonication. The ultrasonication time is 20 minutes and cooled. Then ultrasonication was repeated 15 times to prepare a silicon nitride suspension.

[0053] Put the metal nickel powder with a purity of 99%, a crystal particle size of 50nm, and a mass of 0.2g into ethanol for ultrasonication and stirring for 20 minutes, then ultrasonication after cooling, and repeat 6 times to prepare a metallic nickel dispersion; Mixing with silicon nitride suspension.

[0054] Drying is carried out by heating while stirring. The mixed liquid was placed on the hot stage, the temperature of the hot stage was 130° C., and the two kinds of nanocrystals were fully mixed by heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com