Bearing rotary device

A rotary device and rotary disc technology, applied in rotary conveyors, transportation and packaging, conveyors, etc., can solve the problems of easy falling off of materials, low precision of rotary mechanism, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

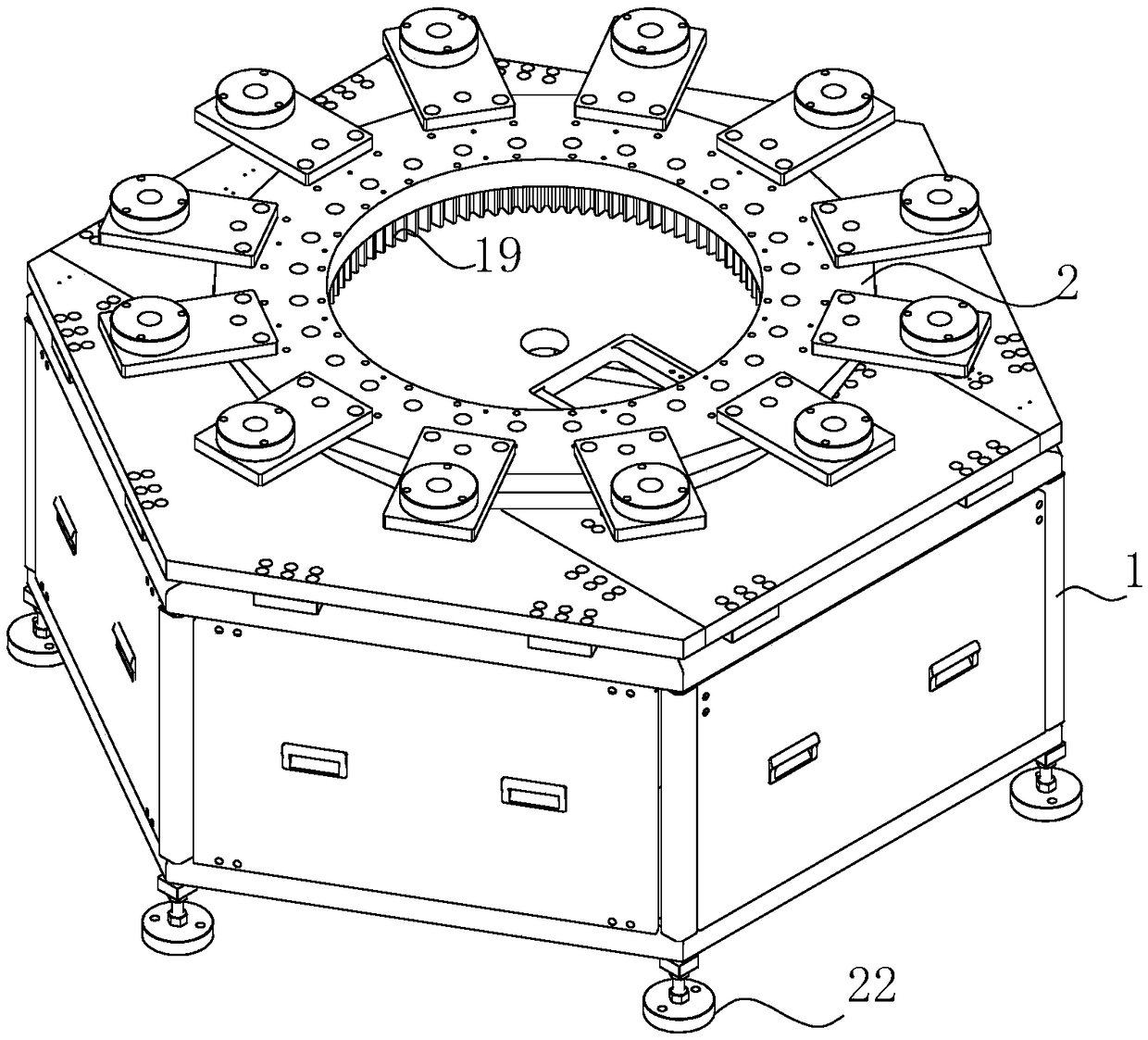

[0039] Such as figure 1 , carrying a rotary device, including a frame 1 and a rotary disc 2, the rotary disc 2 is rotatably connected to the frame 1, and a driver 3 for driving the rotary disc 2 to rotate is arranged on the frame 1, and A clamp 4 for grabbing the material to be grabbed is fixed on the rotary disk 2 .

[0040] The carrying and turning device transfers the material at a certain angle to facilitate the subsequent processing of the material. For example, the initial position of the material is at point A, and the material at point A is placed on the clamp 4 on the rotary table 2 by manual or other automatic structure and is clamped by the clamp 4. The rotary table 2 rotates at a certain angle. At this time, the material at point A The materials at point B will be moved to a new location, point B. For the subsequent processing of materials at point B, corresponding operations will be performed according to actual needs, and no specific introduction will be made he...

Embodiment 2

[0047] This embodiment is an optimization scheme for embodiment 1 in combination with embodiment 1.

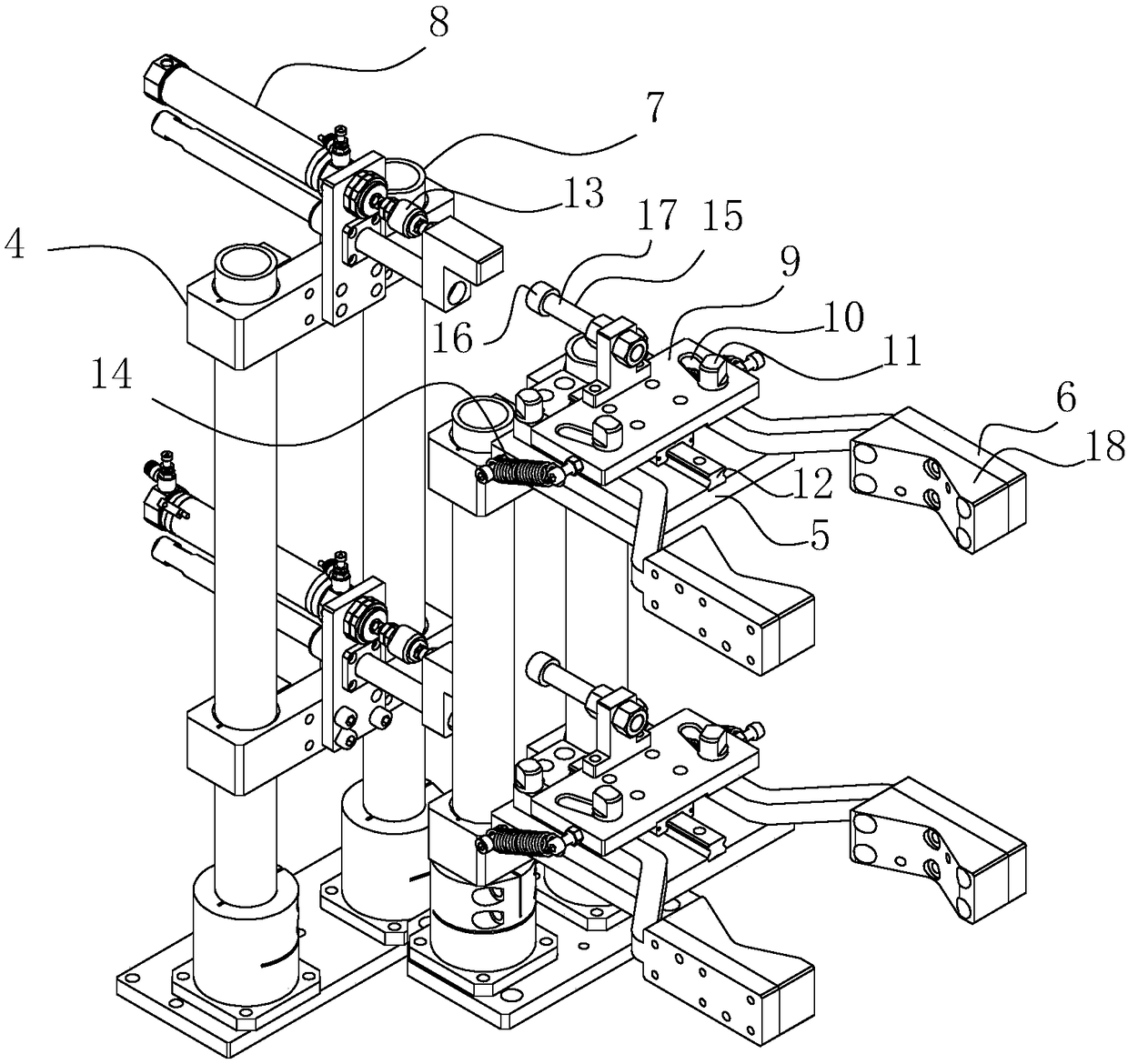

[0048] Such as image 3 A guide rail 12 is provided on the frame body 5 , and a chute matching with the guide rail 12 is provided on the slider 9 , and the guide rail 12 and the frame body 5 are integrally structured. The frame body 5 can be fixed on the frame 1 through a detachable connection.

[0049] The guide rail 12 and the chute are mainly used to improve the movement accuracy of the slider 9. The shape and arrangement of the guide rail 12 and the chute are not specifically limited, and those skilled in the art can freely choose.

Embodiment 3

[0051] This embodiment introduces the connection mode between the output device 8 and the slider 9 .

[0052] Option 1, the output device 8 includes a movable part 13 that outputs a reciprocating linear motion, and the movable part 13 resists the slider 9 and is fixedly connected with the slider 9. In this solution, the movable part 13 of the output device 8 It is fixedly connected with the slider 9, therefore, there should be a one-to-one correspondence relationship between the output device 8 and the slider 9, that is, one fixture 4 should include an independent output device 8. At this time, the output device 8 should rotate together with the rotary table 2, that is, the output device 8 should be fixed on the rotary table 2, or the output device 8 should be fixed on the structure connected with the rotary table 2, so that the output device 8 can be connected with the rotary table. Turntable 2 rotates synchronously.

[0053] Such as image 3 , or, option two, the output de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com