Novel discharge gate structure

A technology of unloading gate and unloading door, which is applied in the direction of unloading device, etc., can solve the problems such as easy splashing of materials, and achieve the effect of solving easy splashing, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

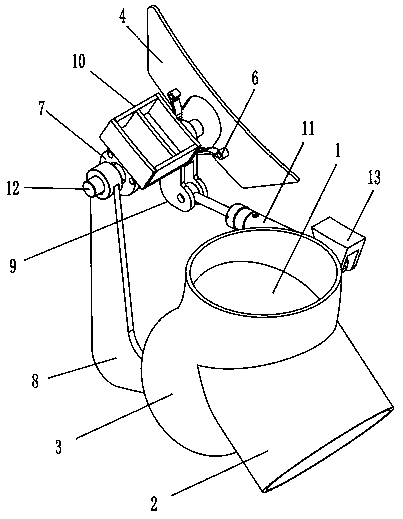

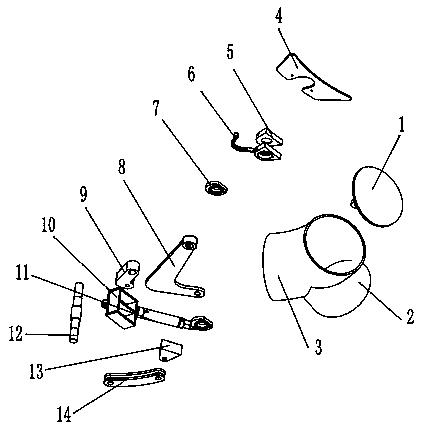

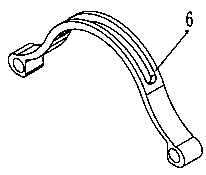

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0020] like Figure 1 to Figure 4 A novel unloading gate structure shown includes a drive part and a transmission structure, the drive part includes an oil cylinder 11, and the transmission structure includes a discharge gate 1, a discharge gate straight pipe 2, a discharge gate Door elbow 3, travel switch fixing plate 4, discharge door bearing seat 5, discharge door semicircle body 6, bearing gland 7, discharge door connecting rod 8, second discharge door connecting rod 9, discharge door bearing Seat base 10, discharge door transmission shaft 12, discharge door oil cylinder base 13 and third discharge door connecting rod 14.

[0021] The middle part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com