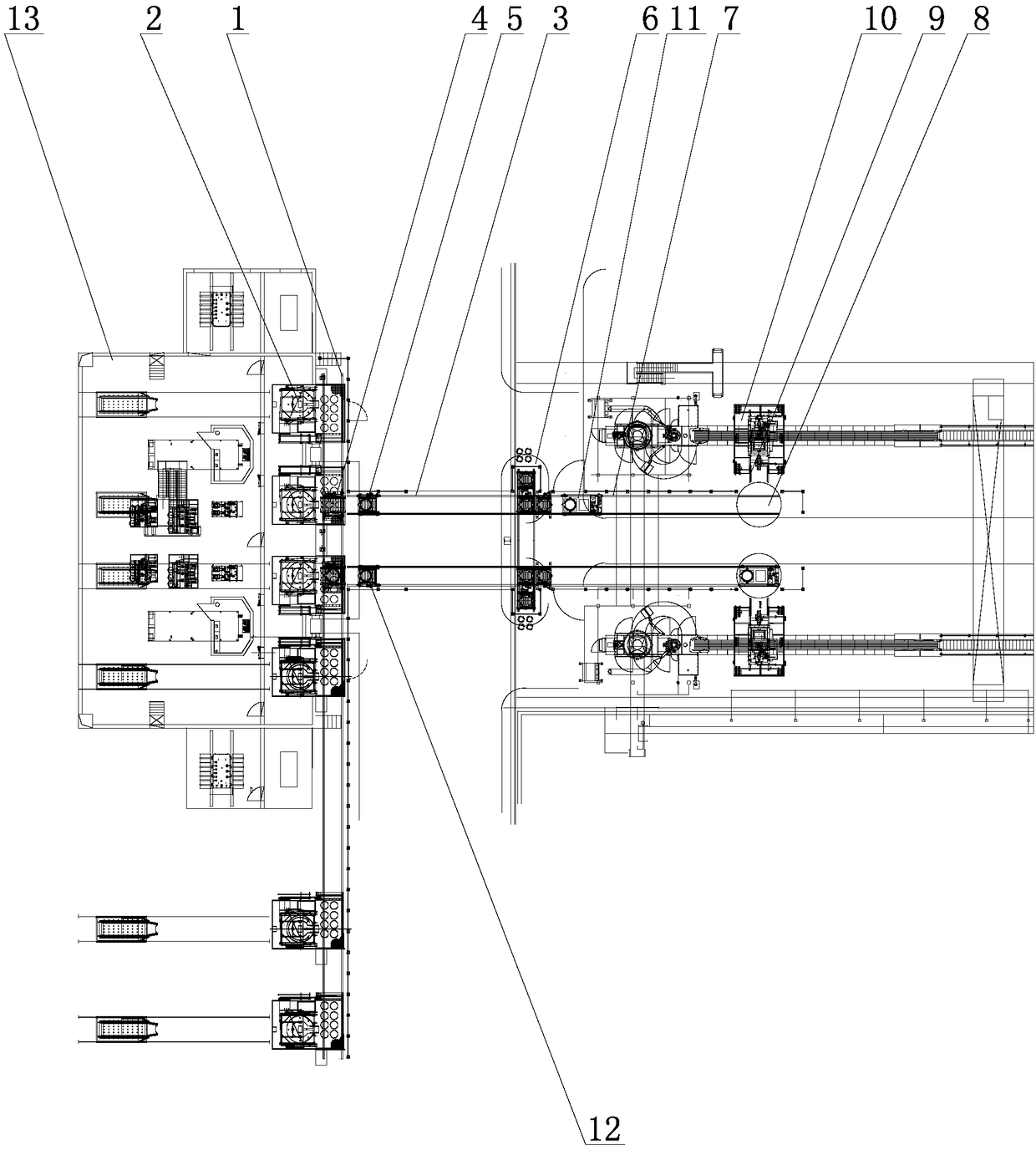

Transfer system of molten iron

A technology for molten iron and transfer vehicles, which is used in casting molten material containers, manufacturing tools, foundry workshops, etc., can solve the problems that need to be further improved, long waiting time, long power supply lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

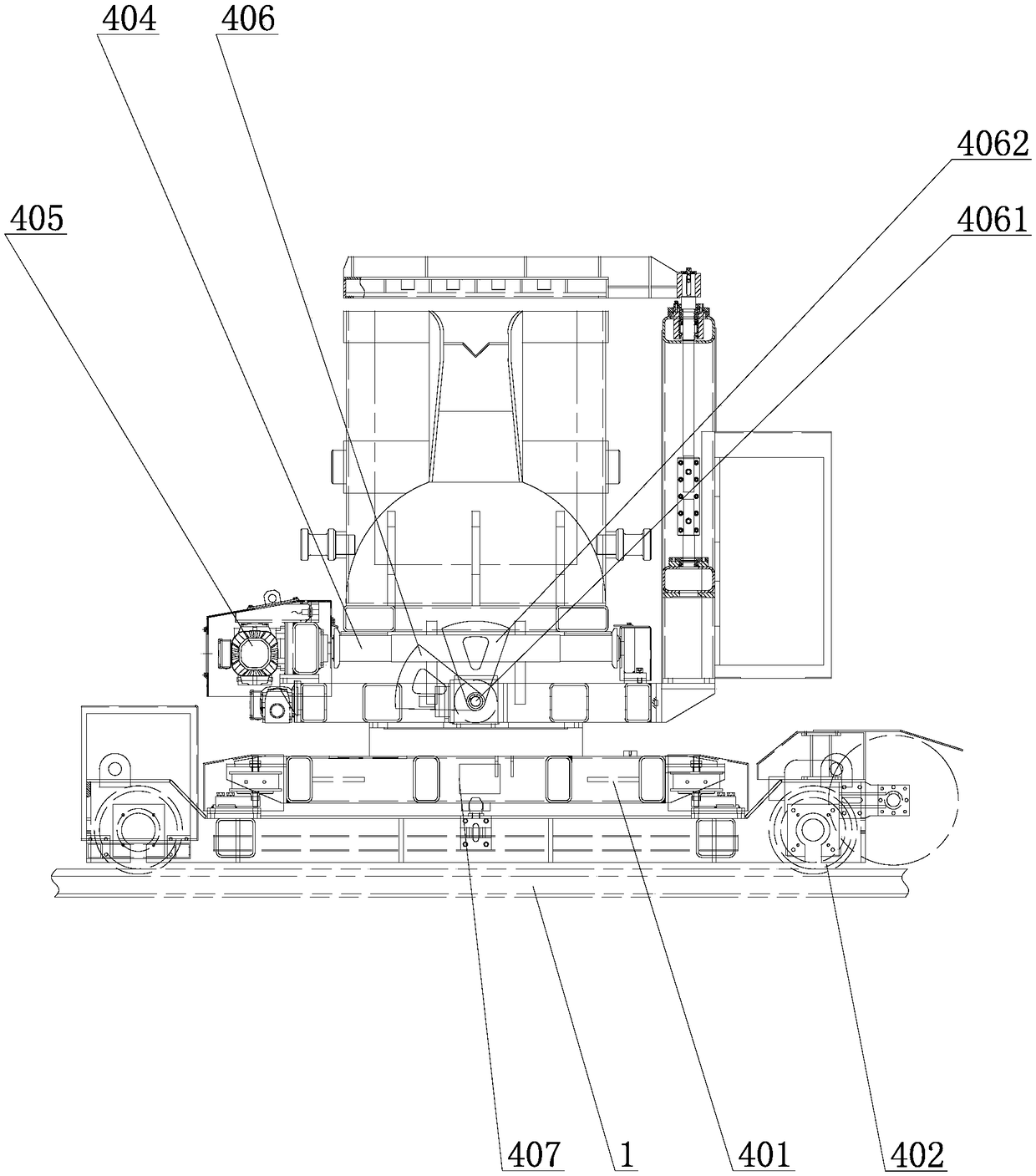

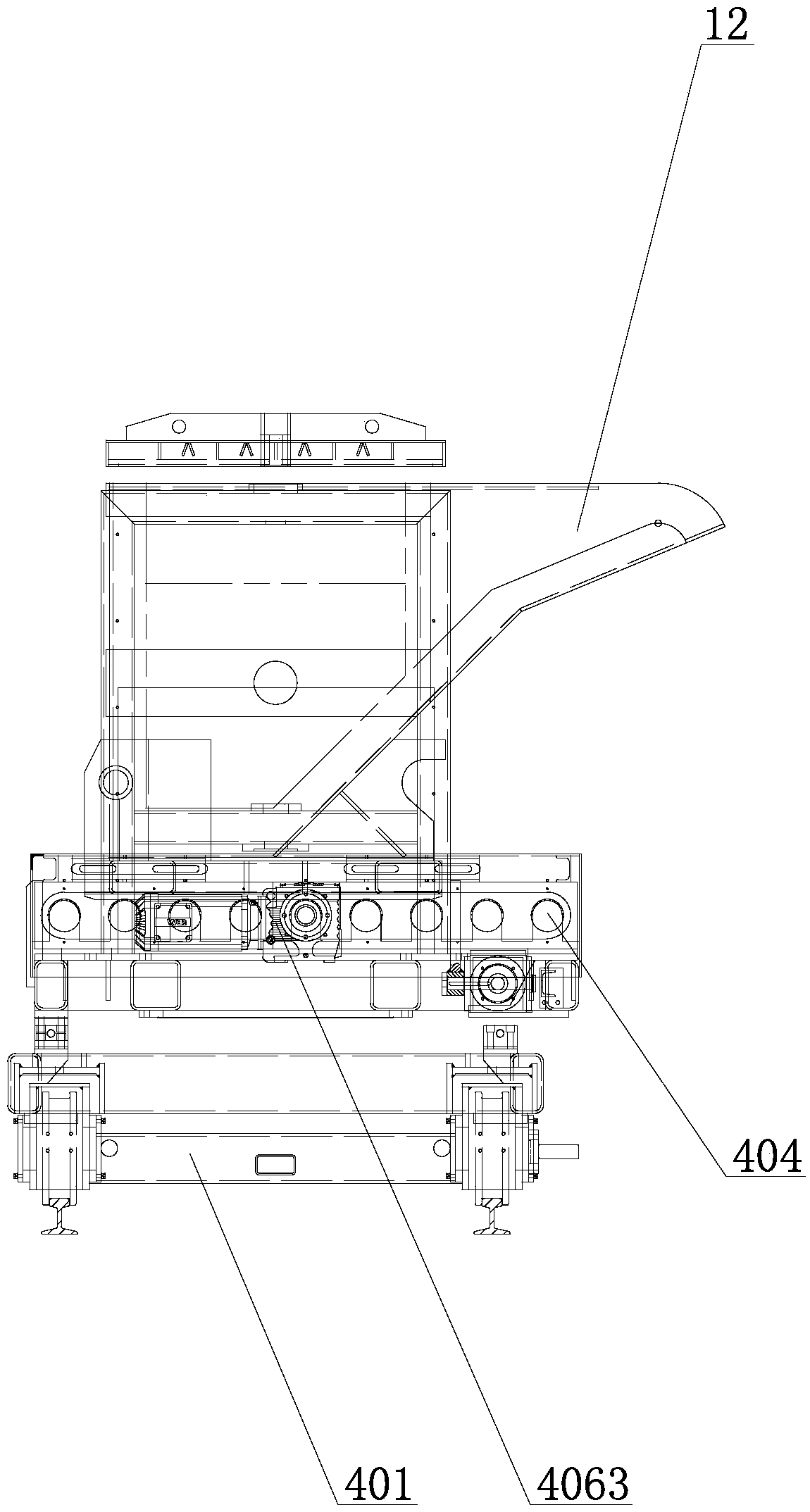

[0037] In order to explain the overall concept of the present invention more clearly, a detailed description will be given below by way of example with reference to the accompanying drawings of the specification.

[0038] In the following description, many specific details are set forth in order to fully understand the present invention. However, the present invention can also be implemented in other ways different from those described here. Therefore, the protection scope of the present invention is not limited to the specific details disclosed below. Limitations of the embodiment.

[0039] In the present invention, it should be understood that the terms "A", "B", "C", and "D" are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance or implicitly indicating the indicated technology The number of features. Therefore, the features defined with "A", "B", "C", and "D" may explicitly or implicitly include one or more of the feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com