Rice steamed sponge cake production process

A production process, rice cake technology, applied in the field of rice cake production technology, can solve the problems of reducing the proofing time of rice cake raw materials, affecting the surface smoothness of rice cake, and uneven surface wrinkles of rice cake, so that it is not easy to age and crack, and saves fermentation Time, the effect of mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

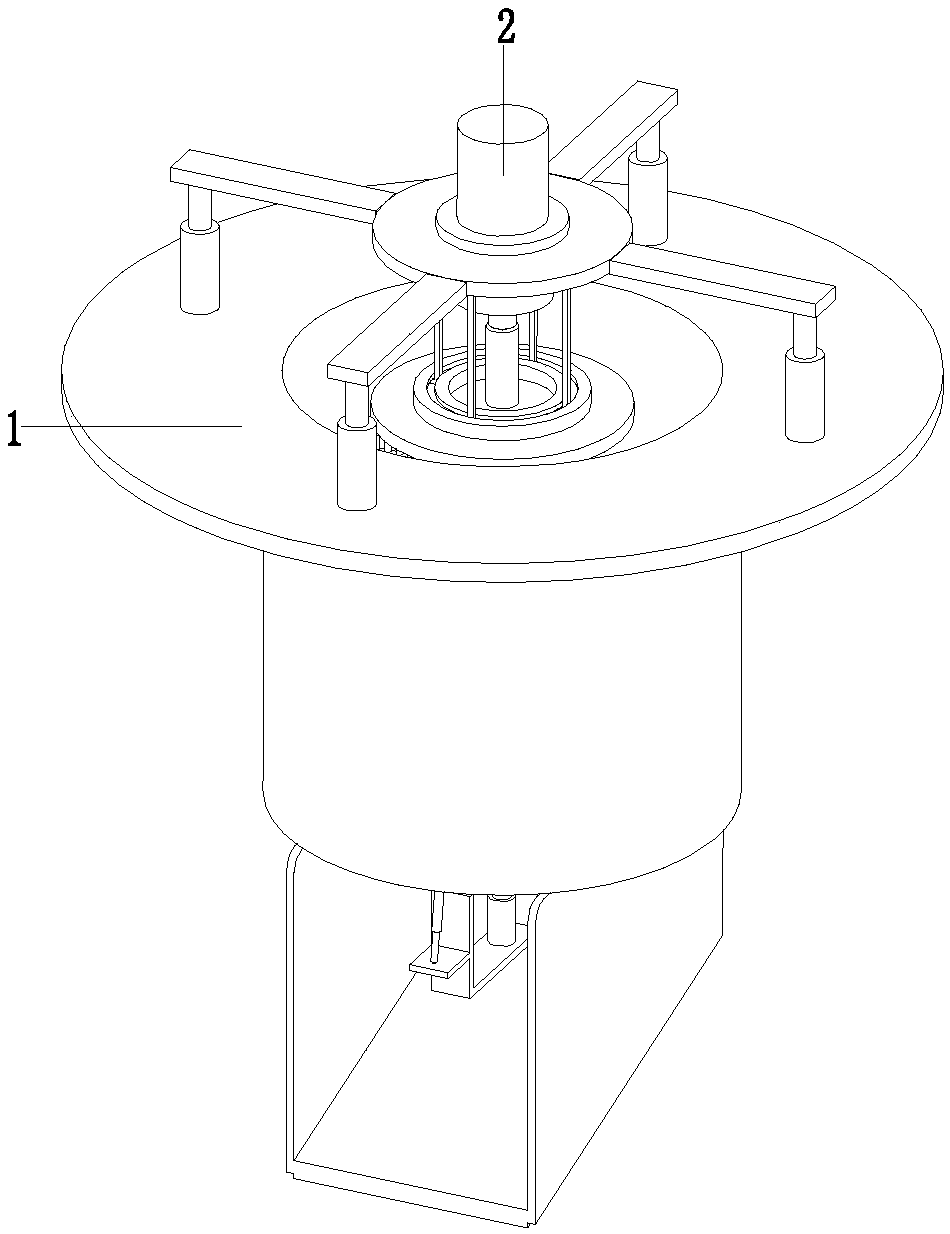

Image

Examples

Embodiment 1

[0028] (1) material selection for primary fermentation: select the following raw materials in parts by weight: Q rice flour 900, sugar 85, yeast 6;

[0029] (2) Powder mixing: the selected material is placed in a powder mixer for 5 minutes, and the powder mixer is a self-mixing high-uniformity powder mixer of ZJH-I;

[0030] (3) Slurry mixing: place the material processed through powder mixing in the slurry mixing device, inject water and stir, and the stirring time is 10min, and the mass parts of the water described are 1400

[0031] (4) One-time proofing: seal the prepared materials and ferment, control the temperature at 36°C, and ferment for 4 hours;

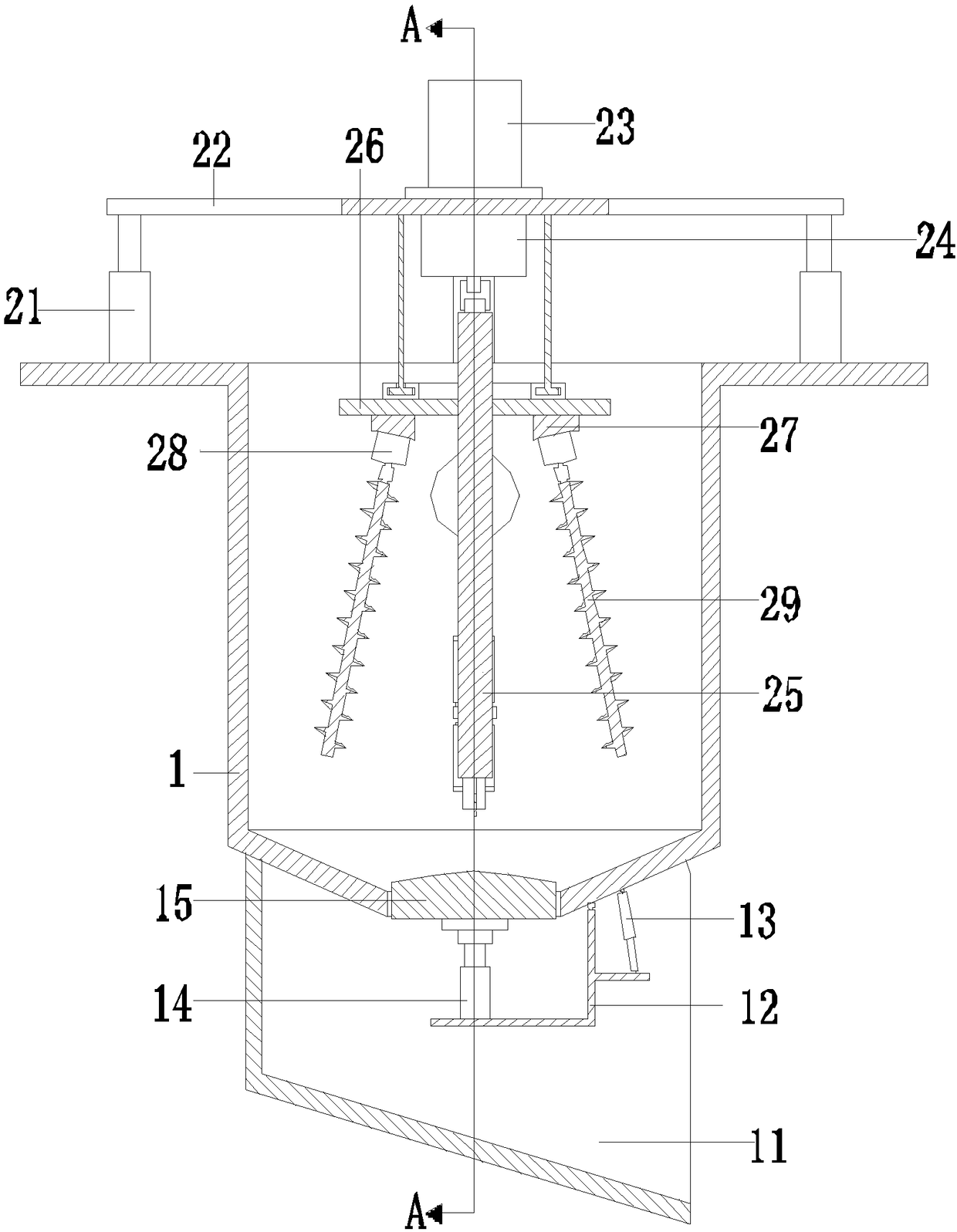

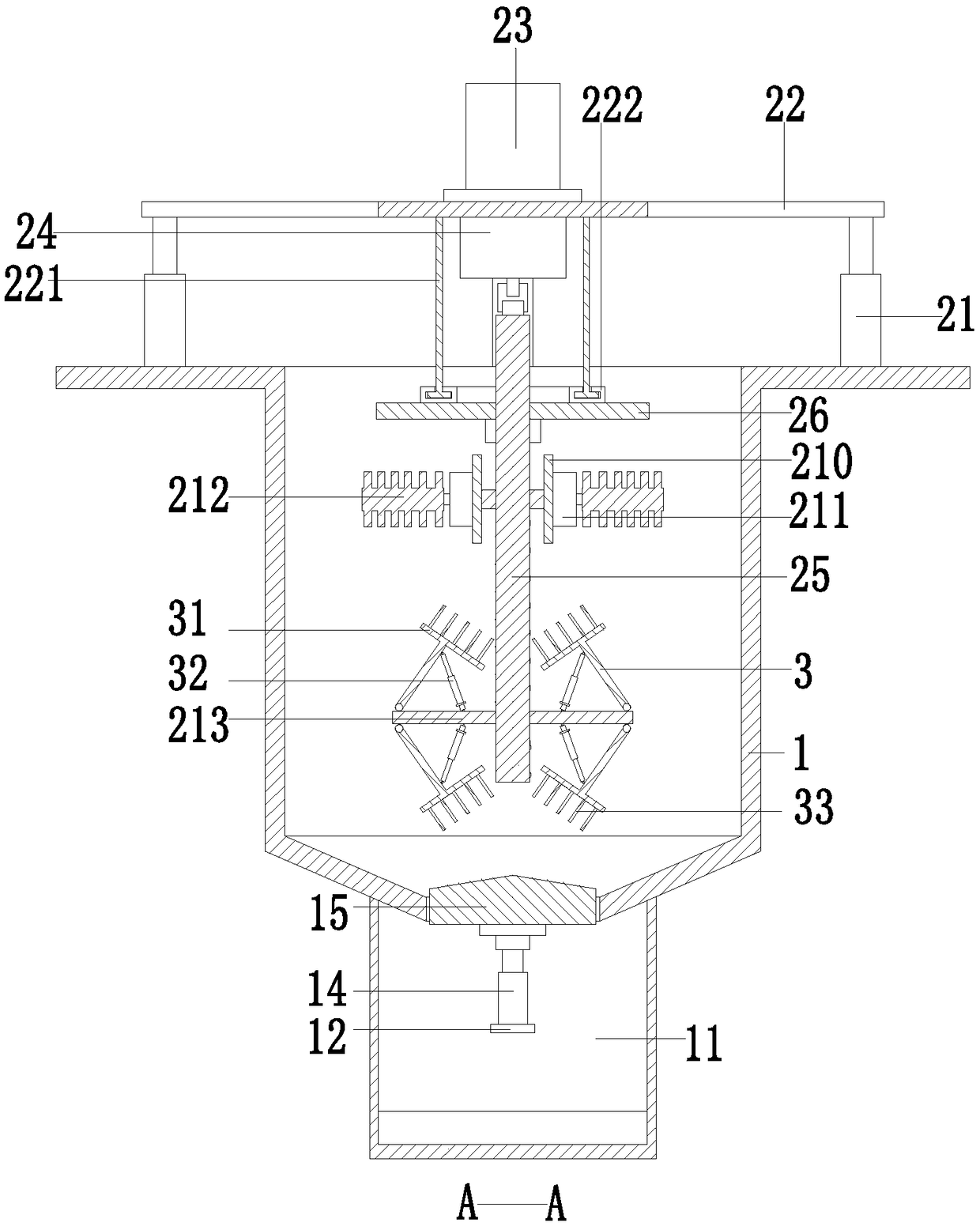

[0032] (5) Secondary fermentation material selection: place the fermented material in the mixing operation barrel 1, add the selected secondary fermentation raw material, and the secondary fermentation raw material is composed of the following materials in parts by weight: sugar 95, baking powder 3.3 , starch 50, stirring f...

Embodiment 2

[0042] (1) material selection for primary fermentation: select the following raw materials in parts by weight: Q rice flour 100, sugar 89, yeast 7;

[0043] (2) Powder mixing: the selected material is placed in a powder mixer for 7.5 minutes, and the powder mixer is a self-mixing high-uniformity powder mixer whose model is ZJH-I;

[0044] (3) pulping: place the material processed through powder mixing in the pulping device, inject water and stir, the stirring time is 1423 parts by mass of the water described in 12.5min,

[0045] (4) One-time proofing: seal the prepared materials and ferment, control the temperature at 38°C, and ferment for 3 hours;

[0046] (5) Secondary fermentation material selection: place the fermented material in the mixing operation barrel 1, add the selected secondary fermentation raw material, and the secondary fermentation raw material is composed of the following materials in parts by weight: sugar 97.5, baking powder 3.4 , starch 55, stirring for 1...

Embodiment 3

[0056] (1) material selection for primary fermentation: select the following raw materials in parts by weight: Q rice flour 1100, sugar 93, yeast 8;

[0057] (2) Powder mixing: the selected material is placed in a powder mixer for 15 minutes, and the powder mixer is a self-mixing high-uniformity powder mixer of ZJH-I;

[0058] (3) pulping: place the material processed through powder mixing in the pulping device, inject water and stir, and the stirring time is 1446 parts by mass of the water described in 15min;

[0059] (4) One-time proofing: seal the prepared materials and ferment, control the temperature at 40°C, and ferment for 5 hours;

[0060] (5) Secondary fermentation material selection: place the fermented material in the mixing operation barrel 1, add the selected secondary fermentation raw material, and the secondary fermentation raw material is composed of the following materials in parts by weight: sugar 100, baking powder 3.5 , starch 60, stirring for 20min;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com