Okra gelatin sweets and preparation method thereof

A technology of okra gel candy and okra gel, which is applied in confectionary, confectionary industry, food ingredients as gelling agent, etc., can solve the problems of poor chewiness and high sugar content, and achieve good chewiness and high Nutritional value, effect of maintaining health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

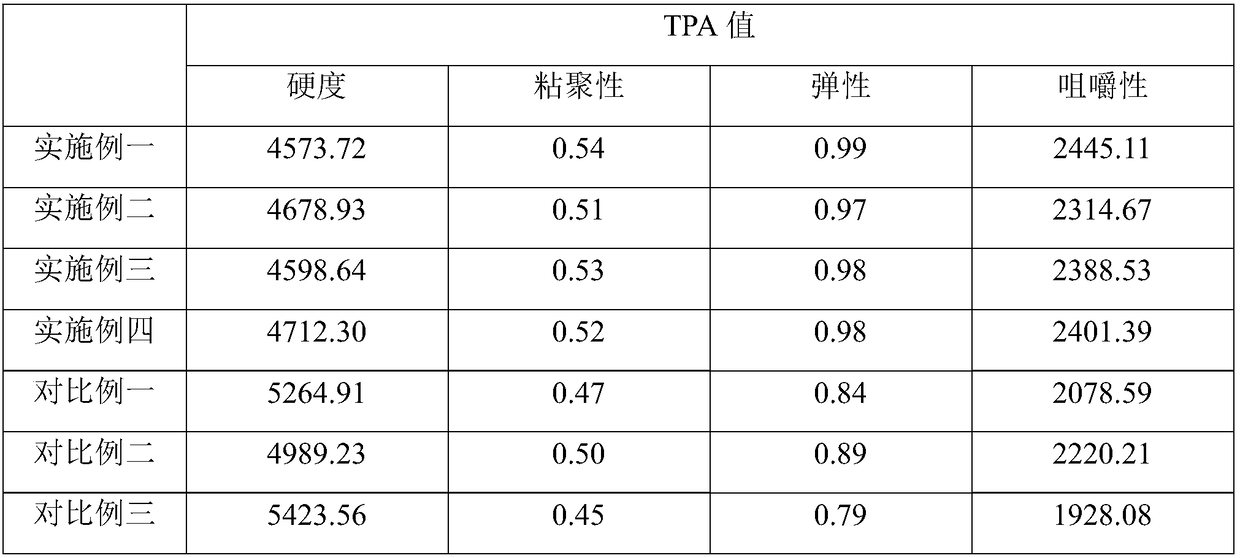

[0028] In order to solve the problems of high hardness, poor chewiness and high sugar content of jelly candy, the present invention proposes a new formula of jelly candy and develops a matching preparation method. In the present invention, the jelly candy uses okra polysaccharide as the main nutritional raw material, is equipped with xylitol, and then adds a gel structure modifier, which can bring good chewiness while ensuring low sugar intake. The jelly candy includes the following components by mass: 4-8 parts of okra polysaccharide, 9-17 parts of compound gum, 16-25 parts of xylitol, 0.2-0.4 part of citric acid, and 0.1-0.2 part of soybean lecithin; The composite glue is made by mixing gelatin and carrageenan at a mass ratio of 5-8:1. Gel candies are produced by:

[0029] (1) Solution preparation: Dissolve xylitol in mineral water or distilled water. When dissolving, the solid-liquid ratio of xylitol to water is 1:2, then add citric acid, stir well to obtain xylitol soluti...

Embodiment 1

[0038]An okra jelly candy, the jelly candy includes the following components by mass: 5 parts of okra polysaccharides, 15 parts of compound glue, 16 parts of xylitol, 0.3 parts of citric acid, and 0.2 parts of soybean lecithin; wherein, Composite gum is formed by mixing gelatin and carrageenan in a mass ratio of 8:1; the gel candy is made by the following method:

[0039] (1) Solution preparation: take xylitol 16g, dissolve it in 32ml distilled water, then add 0.3g citric acid, and stir to obtain xylitol solution; weigh 13.5g gelatin and 1.7g carrageenan, and mix them Mix evenly to obtain a composite glue, then dissolve the composite glue into 45 g of distilled water at a temperature of 30°C, let it stand for 10 minutes, then stir at a speed of 120 rpm for 10 minutes, add 0.2 g of soybean lecithin during the stirring process, and obtain a composite glue solution; Dissolve 5 g of okra polysaccharide in 10 g of distilled water, and stir for 1 hour at 40° C. to obtain a okra poly...

Embodiment 2

[0044] A kind of okra jelly candy is provided, and this jelly candy comprises the component of following mass parts: 8 parts of okra polysaccharides, 17 parts of compound gums, 25 parts of xylitol, 0.4 parts of citric acid, 0.2 parts of soybean lecithin; , the composite gum is mixed by gelatin and carrageenan in a mass ratio of 5:1; the gel candy is made by the following method:

[0045] (1) Solution preparation: take by weighing 25g of xylitol, dissolve it in 50ml of distilled water, then add 0.4 g of citric acid, and stir to obtain a xylitol solution; weigh 14.2g of gelatin and 2.8g of carrageenan, and dissolve them Mix evenly to obtain a composite glue, then dissolve the composite glue into 68g of distilled water at a temperature of 30°C, let it stand for 15 minutes, and then stir at a rate of 100rmp for 15 minutes, add 0.2g soybean lecithin during the stirring process, to obtain a composite glue solution; Dissolve 8 g of okra polysaccharide in 16 g of distilled water, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com