A graphene heating film and a preparation method thereof

A graphene heating film and graphene technology, applied in the field of graphene heating film and its preparation, can solve the problems of high production cost, complex structure of graphene heating film, complicated manufacturing process, etc., and achieve high production efficiency, good flexibility and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

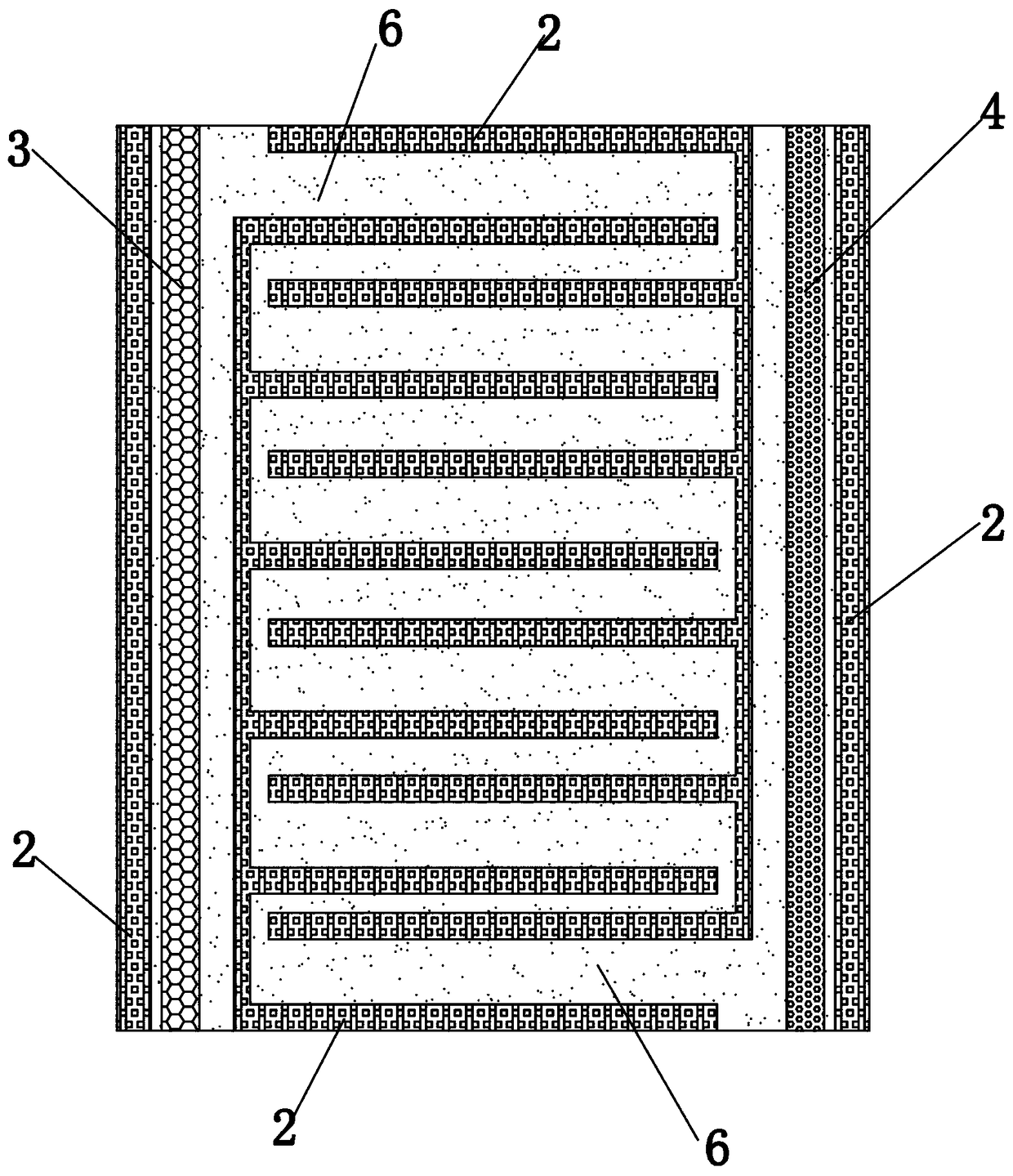

[0027] Example 1, see figure 1 and figure 2 As shown, a kind of graphene heating film, including upper insulating cloth 1, positive electrode conductive tape 3, negative electrode conductive tape 4, intermediate composite film 5 and lower insulating cloth 2, described positive electrode conductive tape 3, negative electrode conductive tape 4 are respectively attached On both sides of the upper surface of the middle composite film 5, the middle composite film 5 is formed by bonding the graphene conductive film 6 and the PE film 7 up and down together, and the middle composite film 5 is provided with a circuitous energization heating circuit 8, One end of the energized heating circuit 8 is connected with the positive conductive tape 3, the other end of the energized heating circuit 8 is connected with the negative electrode conductive tape 4, and the upper insulating cloth 1 and the upper insulating cloth 1 are respectively laid on the middle composite film 5. upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com