A power line connecting terminal

A terminal block and power cord technology, which is applied in the field of electronic equipment, can solve problems such as poor fastening strength, inability to adjust the power cord, poor stability, etc., and achieve the effects of improving structure compactness, convenient connection operation, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

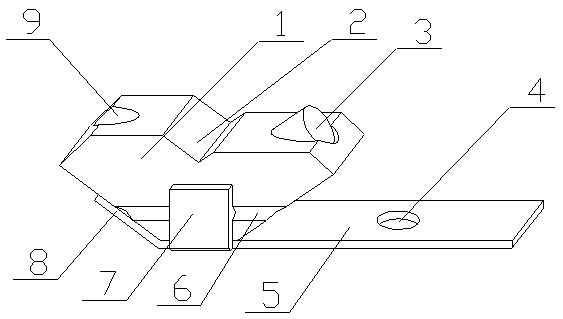

[0032] A power cord terminal of the present invention is realized in this way, and a power cord terminal of the present invention is realized in the following way: a power cord terminal of the present invention includes a connection block (1) and a metal sheet (5), the connection block ( 1) It is clamped on the metal sheet (5) through the clamping grooves (6) at both ends, and the bottom is attached to the metal sheet (5),

[0033] The connection block (1) and the metal sheet (5) are made of copper,

[0034] The cross-section of the connecting block (1) is an inverted trapezoid, and the angle between the two sides of the trapezoid is less than 90°,

[0035] The two ends of the connection block (1) are provided with clamping grooves (6) respectively, and the clamping grooves (6) are parallel to the top surface of the connection block (1).

[0036] The limit card slot (2) is arranged on the top surface of the connection block (1), and runs through the two end surfaces of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com