A non-equivalent area photoelectric hybrid cable

An optoelectronic hybrid cable, equivalent area technology, applied in power cables, power cables including optical transmission elements, insulated cables, etc., can solve problems such as reduced stability, balance pay-off tension, improve operability and application range , to meet the effect of mechanical properties and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

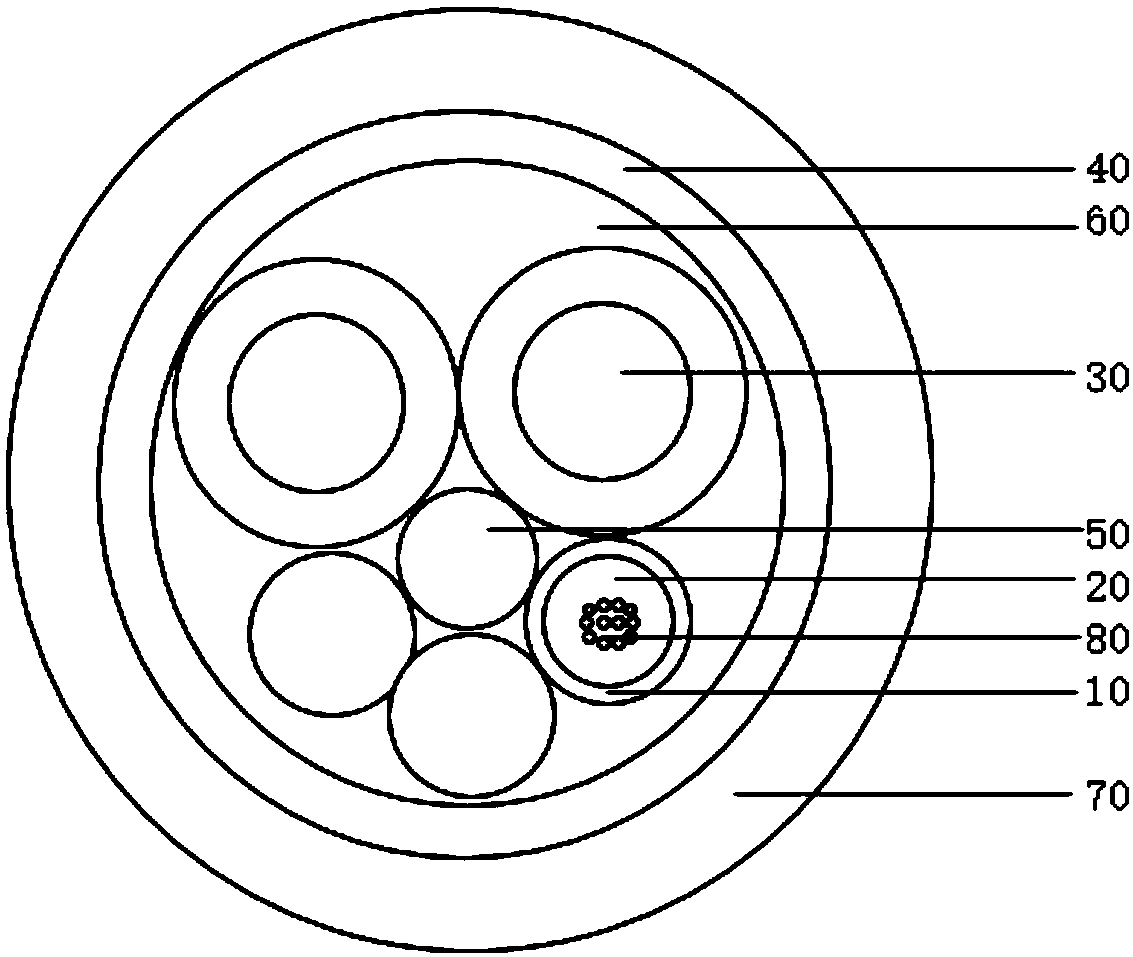

[0021] The application will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the application and implement it, but the examples given are not intended to limit the application.

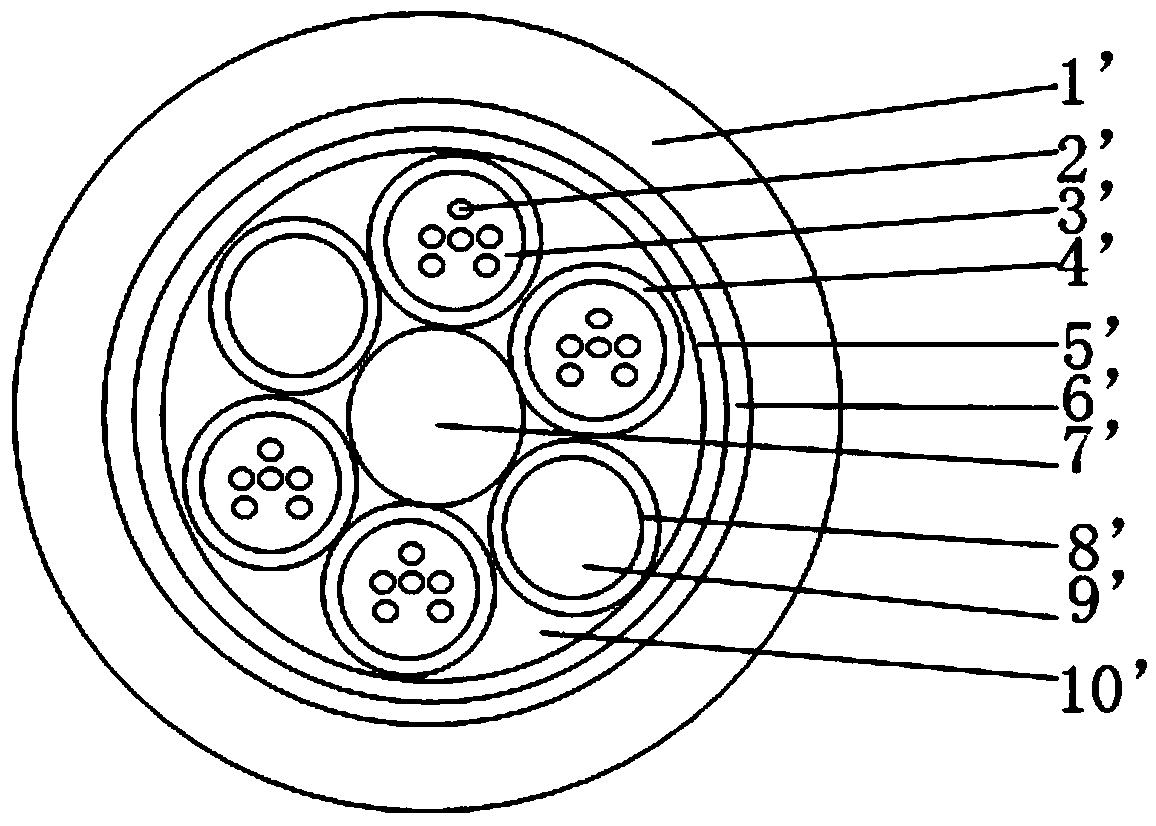

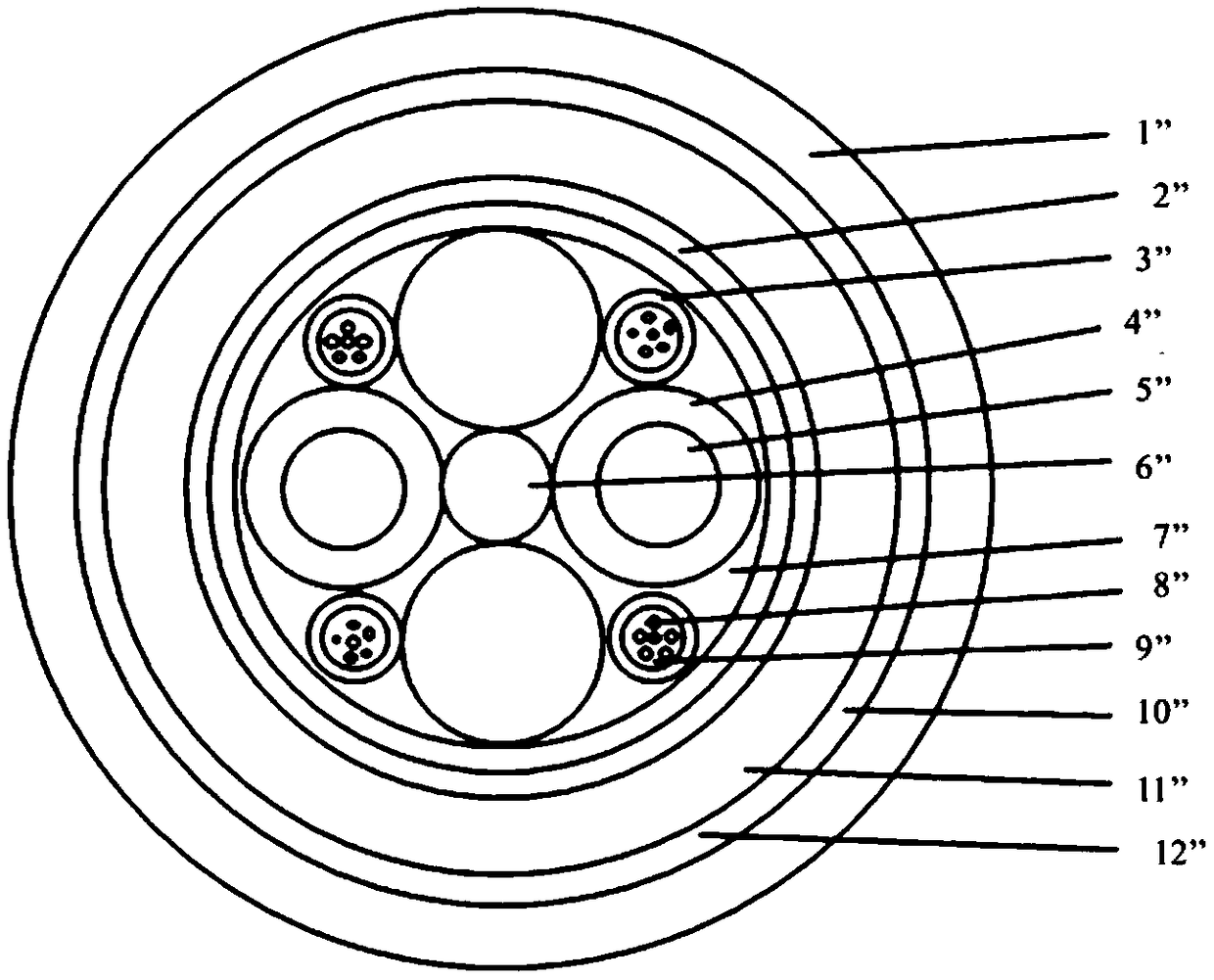

[0022] Such as image 3 As shown, it is a non-equivalent area optical-electrical hybrid cable described in this application. The optical-electrical hybrid cable includes a cable core, a metal composite tape 40 coated outside the cable core, and a metal composite tape coated on the The outer sheath 70 outside the 40, the sheath material involves high-density polyethylene, medium-density polyethylene, low-smoke and halogen-free materials, etc., and a tearing rope of polyester or other materials can be arranged under the sheath. The cable core includes a strengthening member 50, at least one optical unit and at least one electrical unit 30, and the cable core is filled with cable paste 60, and the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com