Method of detecting dispersion stability of battery paste

A technology of dispersion stability and slurry, applied in the direction of flow characteristics, measuring device, particle size analysis, etc., can solve the problems of cumbersome process, irrecoverable damage of slurry, time-consuming, etc., and achieve improved uniformity, low cost, and time consumption. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

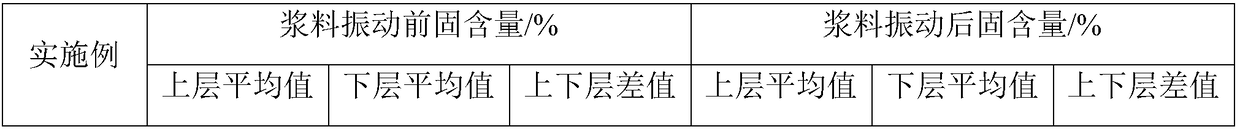

Embodiment 1

[0032] According to the mass ratio of 96:2:1.5:0.5, weigh nickel-cobalt lithium manganese oxide, PVDF, SP, CNT, and NMP as the solvent, and the designed solid content is 68%. According to the process requirements, use a stirred tank to make slurry, and take 50mL of slurry Put the final positive electrode slurry into a 50mL graduated cylinder, then place the graduated cylinder containing the positive electrode slurry on a tap density meter to vibrate for 30min at a frequency of 300 times / min, with a vibration height of 5cm, and use a straw to suck up 1cm from the surface of the slurry. Use a scraper fineness meter to measure the fineness of the slurry at 0.5mL, repeat the suction and measurement operations, and measure three times to obtain the average value; Measure the fineness with a meter, repeat the suction and measurement operations, measure the average three times continuously, and calculate the fineness ratio of the upper layer slurry and the lower layer slurry. Test th...

Embodiment 2

[0034] According to the mass ratio of 95:3:1.5:0.5, weigh nickel-cobalt lithium manganese oxide, PVDF, SP, CNT, and NMP as the solvent, and the designed solid content is 68%. According to the process requirements, use a stirred tank to make slurry, and take 50mL of slurry Put the final positive electrode slurry into a 50mL graduated cylinder, then place the graduated cylinder containing the positive electrode slurry on a tap density meter to vibrate for 30min at a frequency of 300 times / min, with a vibration height of 1cm, and use a pipette gun to absorb the amount of slurry Slurry 0.2mL at 5cm from the surface, measure the fineness with a scraper fineness meter, repeat the suction and measurement operations, and measure three times to obtain the average value; The fineness meter measures the fineness, repeats the suction and measurement operations, and calculates the average value for three consecutive measurements, and calculates the fineness ratio of the upper layer slurry a...

Embodiment 3

[0036] According to the mass ratio of 97:1:1.5:0.5, weigh nickel-cobalt lithium manganese oxide, PVDF, SP, CNT, and NMP as the solvent, and the designed solid content is 68%. According to the process requirements, use a stirred tank to make slurry, and take 50mL of slurry Put the final positive electrode slurry into a 50mL graduated cylinder, then place the graduated cylinder containing the positive electrode slurry on a tap density meter to vibrate for 30min at a frequency of 300 times / min, with a vibration height of 5cm, and use a pipette to absorb the amount of the slurry Slurry 0.8mL at 8cm from the surface, measure the fineness with a scraper fineness meter, repeat the suction and measurement operations, and measure three times to get the average value; The fineness meter measures the fineness, repeats the suction and measurement operations, measures three times in total, calculates the average value, and calculates the fineness ratio of the upper layer slurry and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com