Adaptive bed load sampling device and transport rate measuring method

A sampling device and self-adaptive technology, applied in the sampling device and weighing by removing a certain component, can solve the problems of inaccurate sampling and inability to adapt to the single-width sediment transport rate due to unstable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

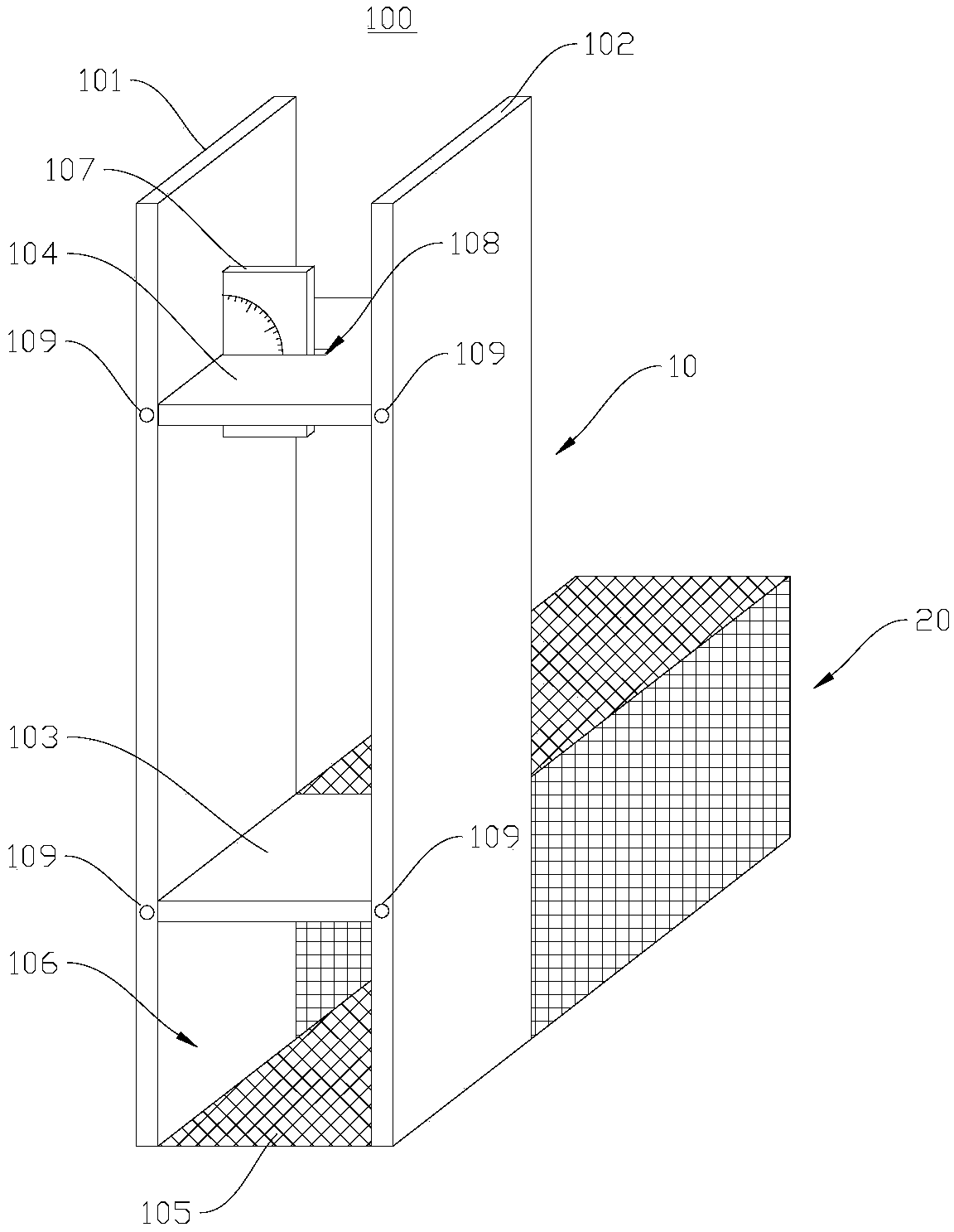

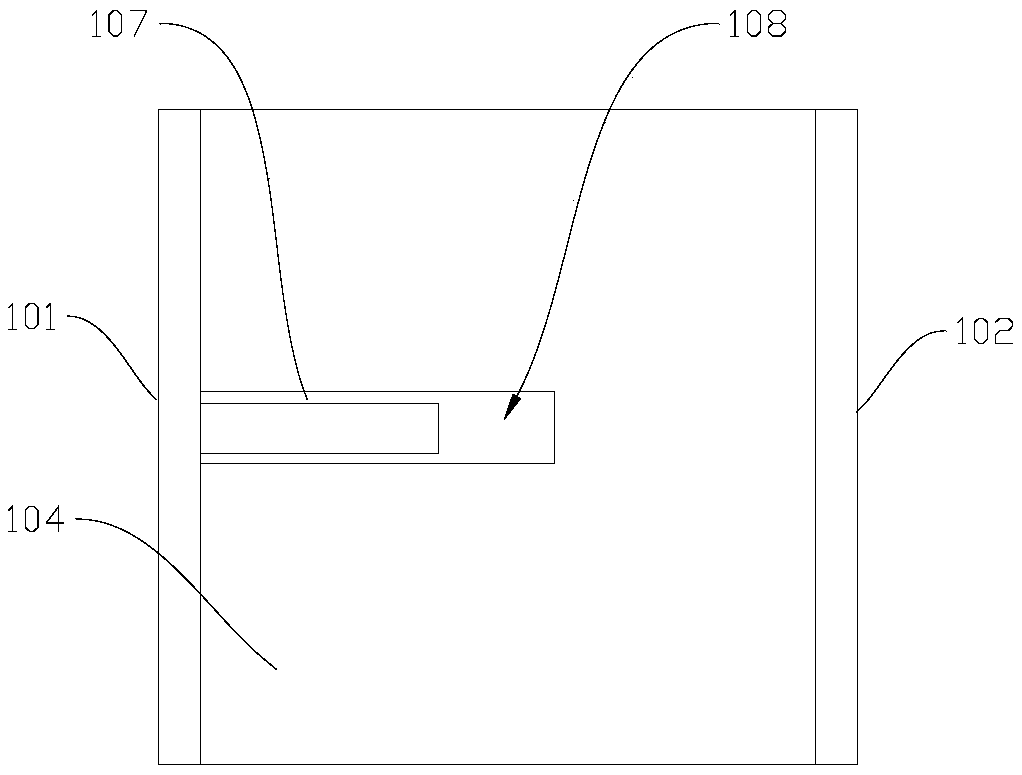

[0031] Please refer to figure 1 The shown adaptive mass sampling device 100 includes: an adaptive support frame 10 and a sampling net bag 20 . The sampling net bag 20 is arranged on the bottom of the self-adaptive support frame 10, and is used for collecting the moving matter. The adaptive support frame 10 includes a first support plate 101 , a second support plate 102 , a first connection plate 103 , a second connection plate 104 and a mesh soft bottom plate 105 .

[0032] Please refer to figure 1 , the first supporting plate 101 and the second supporting plate 102 are parallel to each other, the first connecting plate 103 and the second connecting plate 104 are parallel to each other, and the mesh soft bottom plate 105 is respectively connected to the bottom of the first supporting plate 101 and the second supporting plate 102 . The first connecting plate 103 and the second connecting plate 104 are successively arranged at intervals between the first supporting plate 101 ...

Embodiment 2

[0037] A method for measuring the sediment transport rate of moving mass, the above-mentioned adaptive mass sampling device 100 performs sampling and then calculates the sand transport rate, which includes the following specific steps:

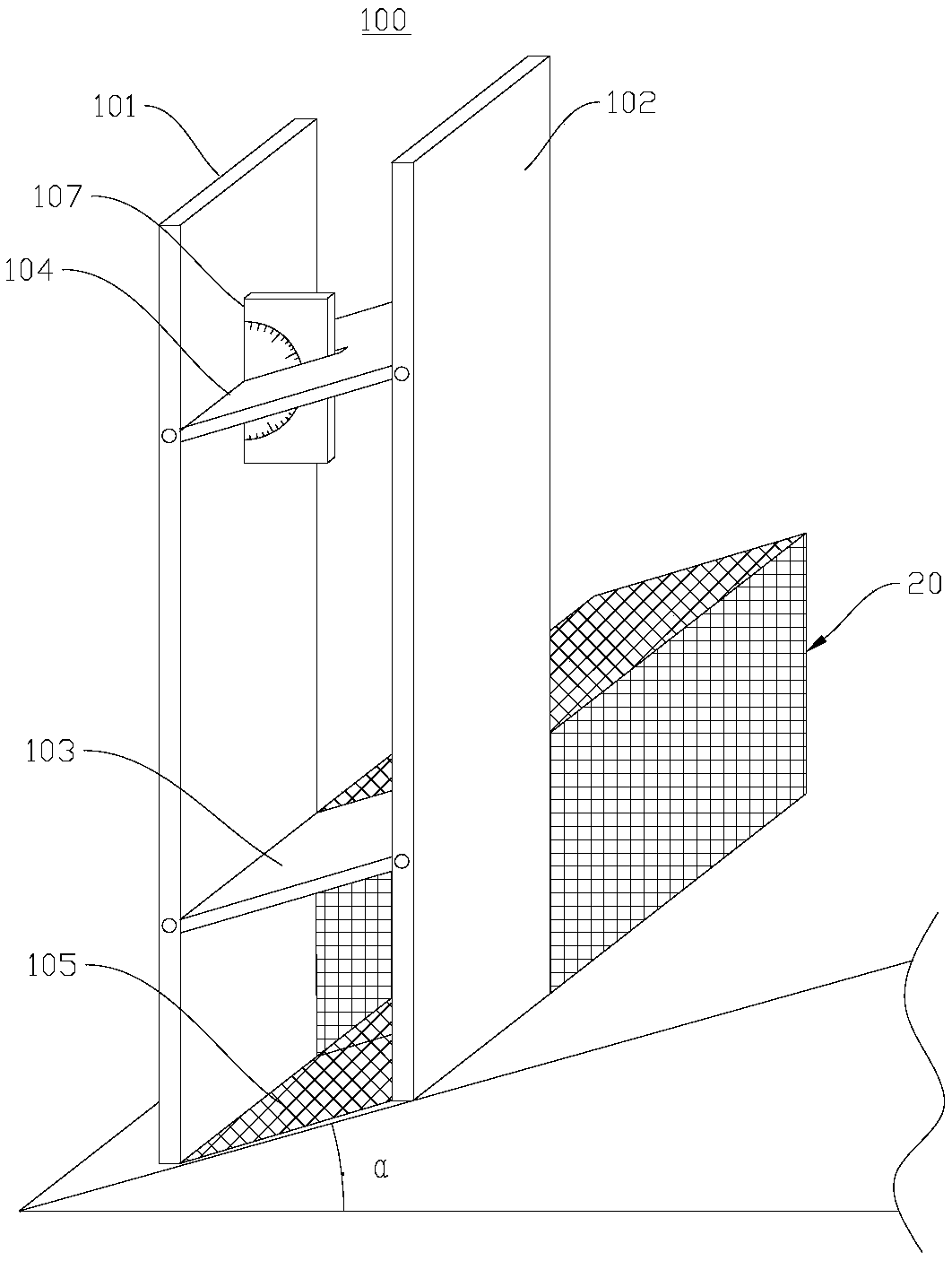

[0038] (1) Place the bottom of the self-adaptive mass sampling device 100 underwater, keep the self-adaptive support frame 10 upright, and keep the sampling inlet 106 and the sampling net bag 20 of the self-adaptive support frame 10 to be located in the water, while the sampling inlet 106 is located The plane is perpendicular to the direction of water flow;

[0039] (2) Adjust the inclination angle of the adaptive support frame 10 according to the slope of the river bed, so that the bottoms of the first support plate 101 and the second support plate 102 of the adaptive support and the mesh soft bottom plate 105 are all attached to the surface of the river bed, and then fixed Adaptive support frame 10;

[0040] (3) Read the angle α between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com