Magnetic crushing online automatic test all-in-one machine

An automatic testing and all-in-one machine technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems that affect production efficiency, occupy production space, and cumbersome production processes, so as to improve production efficiency and improve production Quality, the effect of guaranteeing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

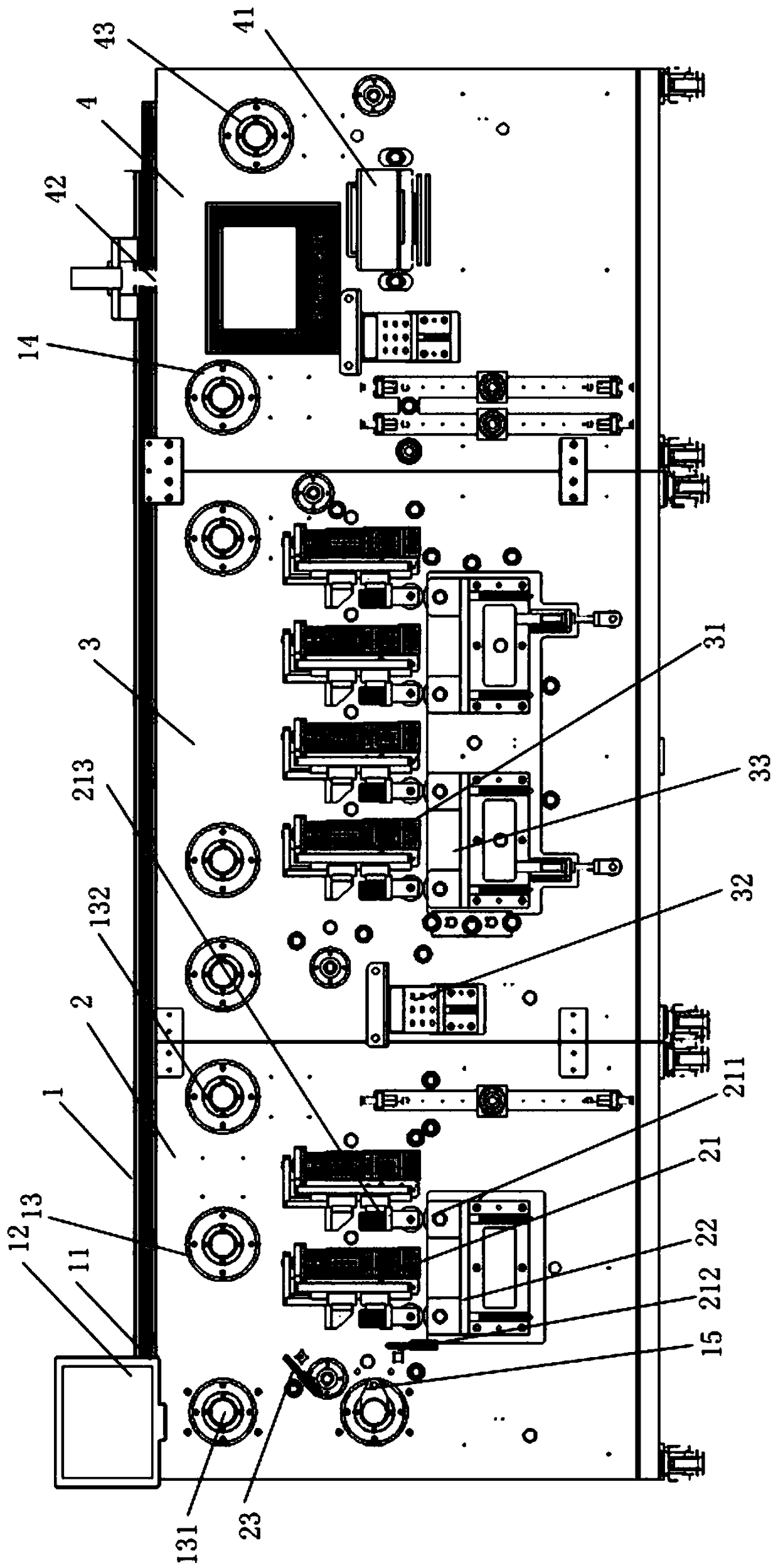

[0037] see figure 1 , this embodiment shows a magnetic crushing online automatic test integrated machine, including a device main body 1, the device main body 1 is composed of a film coating section 2, a magnetic crushing section 3, and a testing section 4 arranged in sequence;

[0038] Under conventional settings, the main body of the equipment 1 includes a main machine and a fixed frame 11, a discharging mechanism 13, a winding mechanism 14, a control system, a conveying mechanism, a static elimination device, an automatic deviation correction device 15 and a surplus material winding device, and is also provided with Movable human-computer interaction screen 12.

[0039] Wherein, the lamination section 2 includes a lamination mechanism 21, a tension mechanism 22, a lamination correction mechanism 23 driven by an automatic correction motor, and a lamination servo motor for driving the lamination mechanism 21 and the tension mechanism 22;

[0040] The magnetic crushing sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com