Paint spraying equipment capable of realizing switching between high-pressure spraying and low-pressure spraying quickly

A kind of painting equipment, high and low pressure technology, applied in the direction of painting room, spraying device, etc., can solve the problems of long production cycle, high paint waste, large painting diameter, etc., to achieve the effect of convenient production, unique design, and enhanced applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

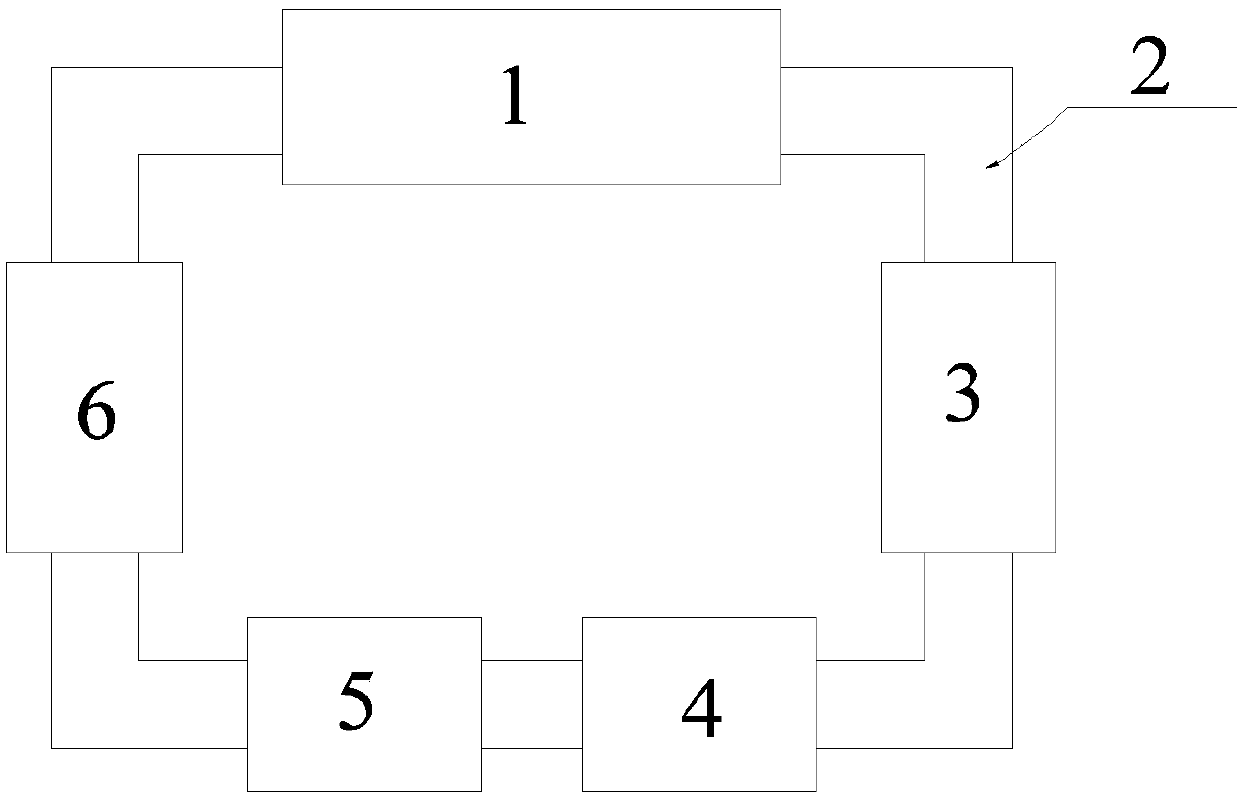

[0019] Such as figure 1 As shown, the paint spraying equipment that can quickly realize the switching between high and low pressure spraying is equipped with a product placement and collection device 1, a first station unit 3, a first spraying device 4, a second spraying device 5 and a second spraying device 5 on the circular flow transmission line 2 Two station unit 6.

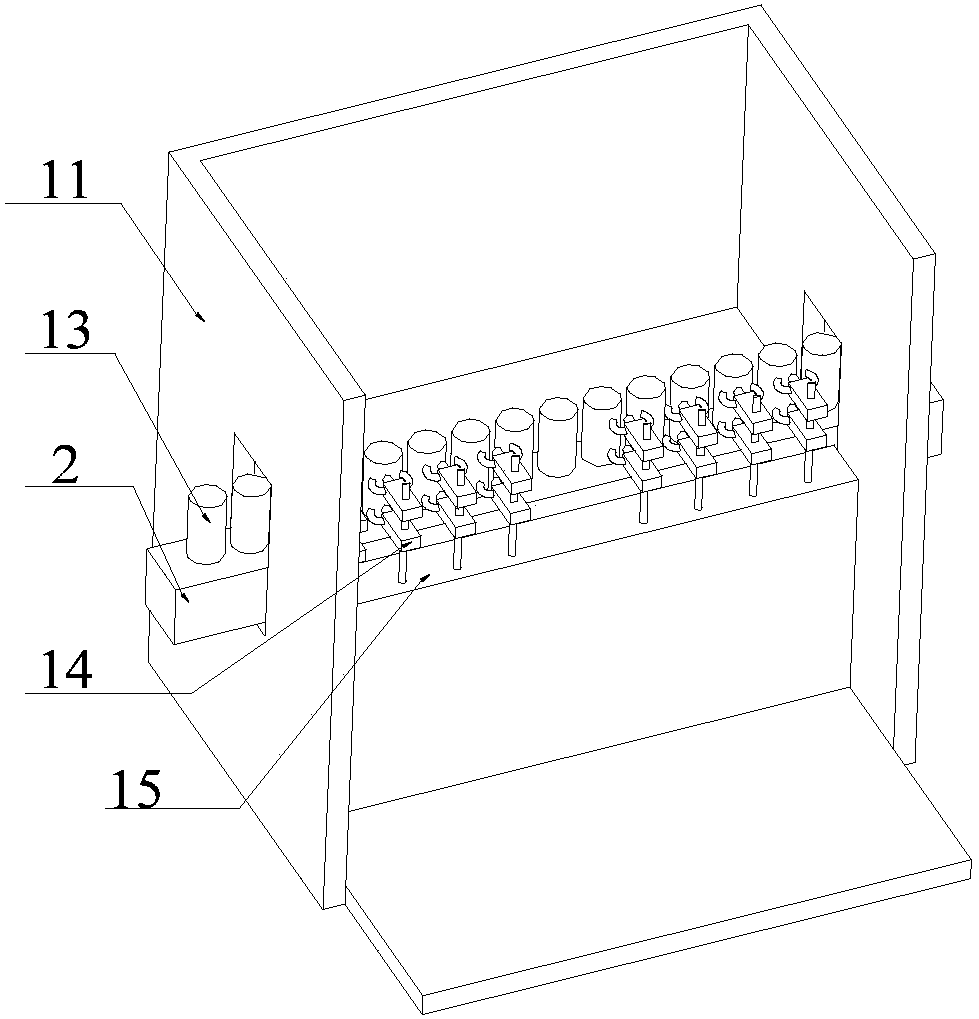

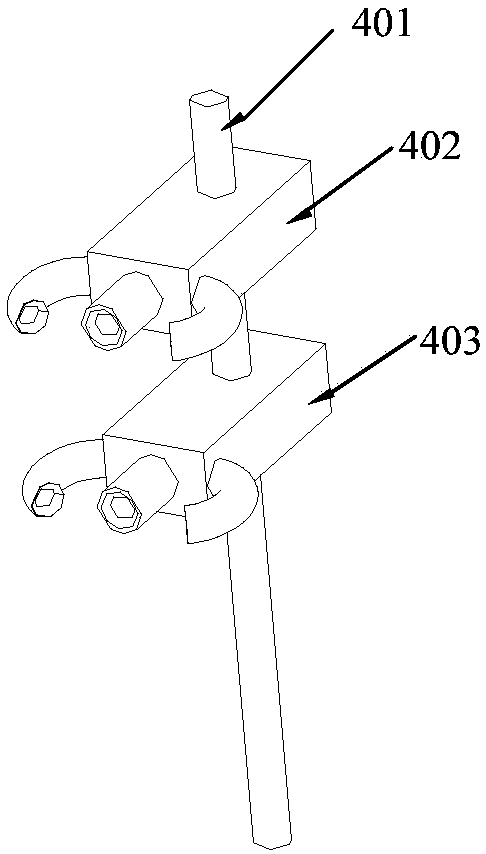

[0020] The first spraying device 4 and the second spraying device 5 have the same structure, as figure 2 As shown, they all include a box body 11 and a spraying mechanism 14. A channel for the water transmission line 2 to run through is provided in the box body 11. The product 13 is carried on the water transmission line 2. A workbench 15 is arranged along one side of the channel. On the workbench 15 A plurality of spraying mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com