A method for plugging the end of pipe jacking curtain

A pipe curtain and end technology, which is applied in the field of waterproof construction of the pipe curtain end of the pipe jacking tunnel in the whole process, to facilitate grouting treatment, save water seepage treatment costs, and contribute to the safety of the tunnel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

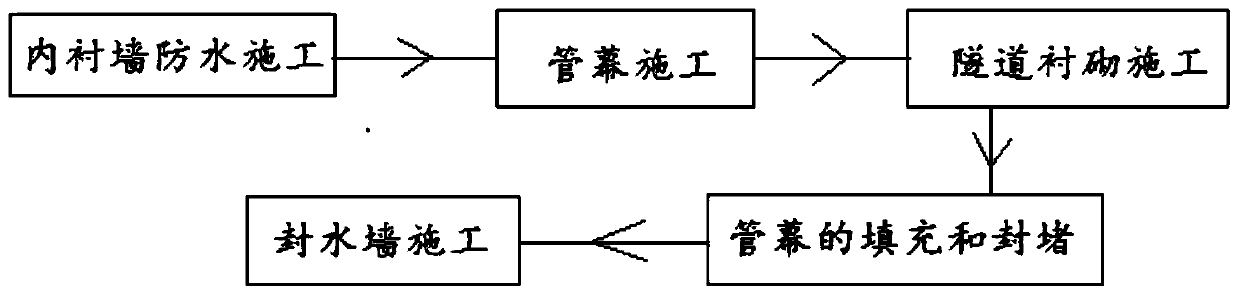

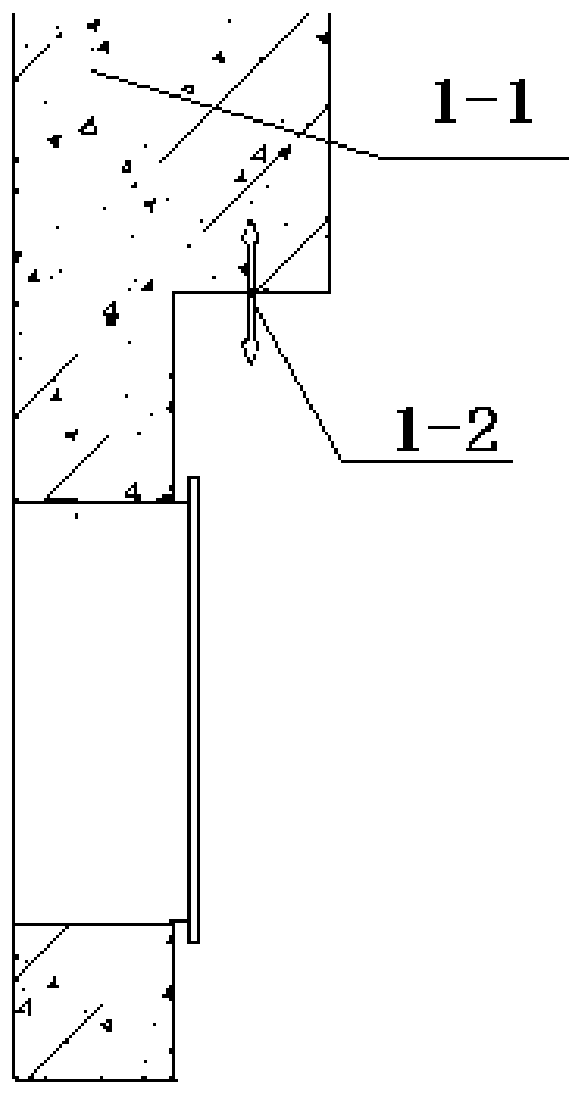

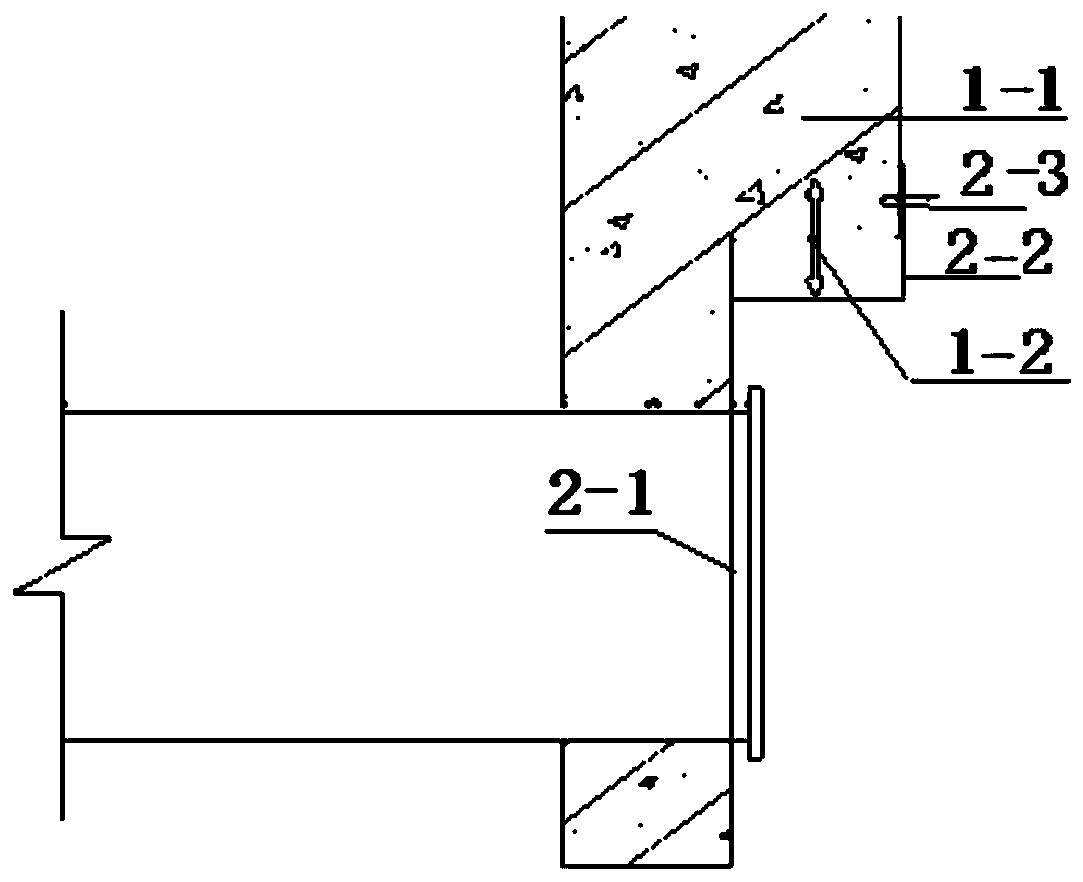

[0029] Such as Figure 1-6 As shown, a method for sealing the end of a pipe-jacking pipe curtain. In the construction of a pipe-jacking tunnel, steel edge waterstops 1-2 are installed on the inner lining wall 1-1 and the three linings of the pipe-jacking tunnel in the early stage, grouting is sealed, and the later stage The end of pipe curtain 3-1 is welded and sealed with steel plate 2-1, filled with concrete, laid with waterproof coiled material, constructed as water sealing wall 4-2, and grouted to seal the pipe curtain 3-1.

[0030] The specific technical scheme is carried out according to the following steps:

[0031] a. Waterproof construction of lining wall 1-1 at the end of pipe curtain 3-1

[0032] During the construction of the inner lining wall 1-1, install the pipe jacking orifice pipe and the steel edge waterstop 1-2 and reserve the grouting pipe 3-2, and use steel plates to protect the steel edge waterstop 1-2 , wherein the construction of the lining wall 1-1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com