Double-hydraulic-motor synchronous positioning rotary table assembly

A technology of synchronous positioning and hydraulic motors, which is applied to workbenches, manufacturing tools, gear transmissions, etc., can solve the problems that it takes a certain amount of time for the piston rod to extend out, and it is difficult to ensure the accurate positioning of the turntable, so as to achieve simple structure, cost reduction, and running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

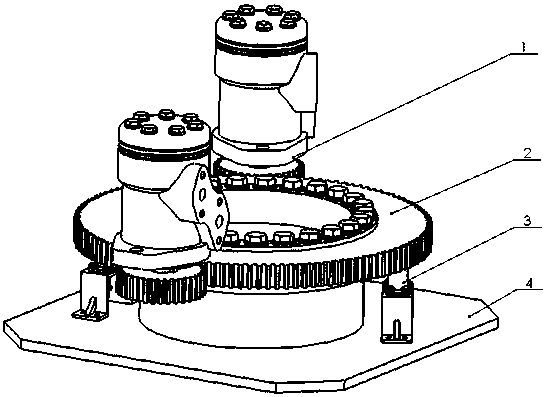

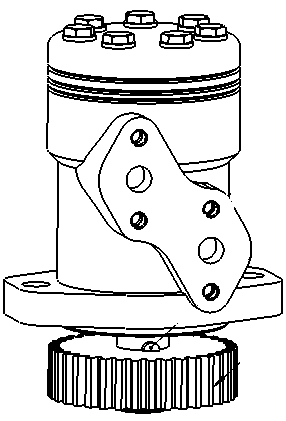

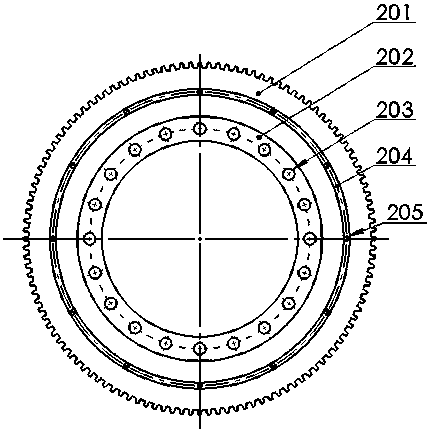

[0022] Such as Figure 1 to Figure 5 As shown, a dual hydraulic motor synchronous positioning turntable assembly according to the present invention includes a positioning table 4, a hydraulic motor assembly 1 and a toothed outer ring turntable bearing 2, and the positioning table 4 includes a positioning table base 402, and the positioning table base 402 A number of connecting threaded holes 401 are opened on the top. The toothed outer ring slewing bearing 2 includes an outer gear ring 201 and an inner gear ring 202. The hydraulic motor assembly 1 meshes with the toothed outer ring slewing bearing 2 through gears. . A plurality of connection holes 203 are opened on the inner ring gear 202, the outer ring gear 201 and the hydraulic motor assembly 1 are geared together, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com