High-boosting double-cylinder four-piston three-crankshaft full-linear-symmetry two-stroke engine

A completely symmetrical engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of low thermal efficiency conversion of engines, fuel consumption, multi-use, etc., and achieve the effects of self-vibration elimination, small operating vibration, and mechanical wear elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

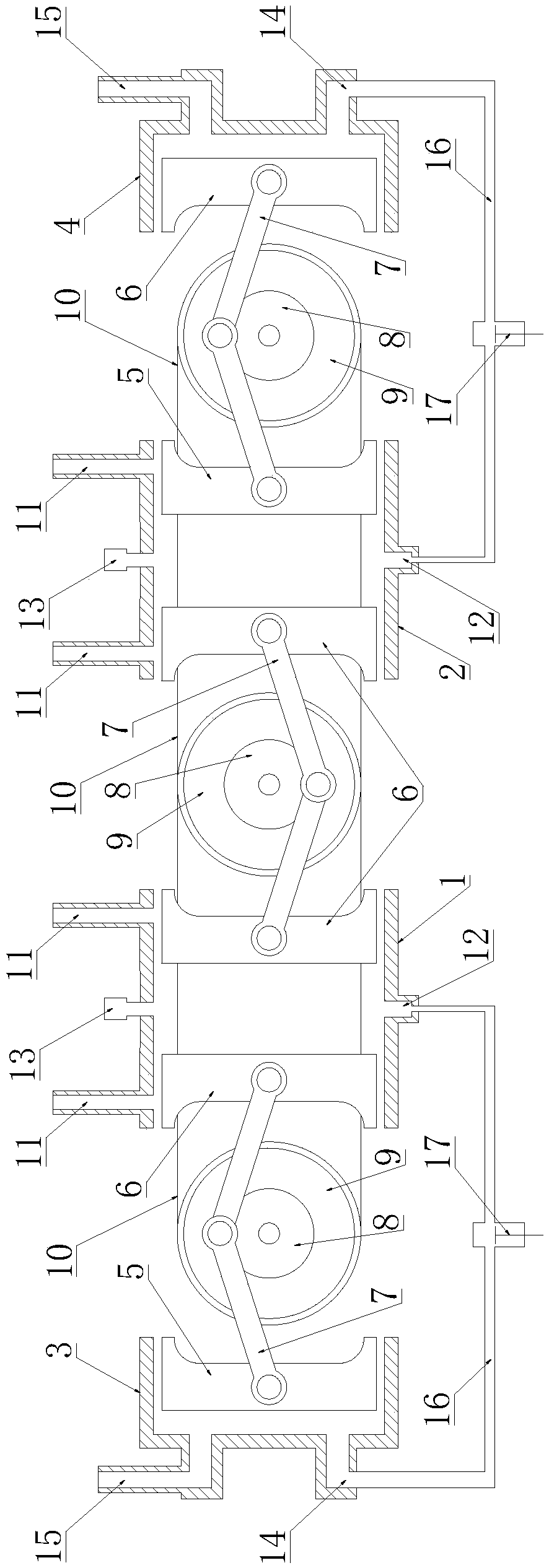

[0022] Such as figure 1 as shown, figure 1 It shows the highly boosted two-cylinder four-piston three-crankshaft 8 straight-line fully symmetrical two-stroke engine provided by the embodiment of the invention, including the first cylinder 1 and the second cylinder 2, and the outer sides of the first cylinder 1 and the second cylinder 2 are respectively arranged correspondingly. There are first high boost steam intake cylinder 3 and second high boost steam intake cylinder 4, both of which are equipped with high boost steam intake cylinder 3 and second high boost steam intake cylinder 4. The piston 5, the first cylinder 1 and the second cylinder 2 are all provided with a working piston 6, the piston 5 and the working piston 6 for high pressurized steam intake, and the working piston 6 in the first cylinder 1 and the working piston 6 in the second cylinder 2 The acting pistons 6 are all connected by crank arms 7, and the crank arms 7 are connected to the corresponding synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com