Novel forging workpiece feeding mechanism

A technology of feeding mechanism and discharging mechanism, applied in forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve the problems of poor running balance, troublesome replacement, low precision, etc., and achieve fast replacement and convenient maintenance , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

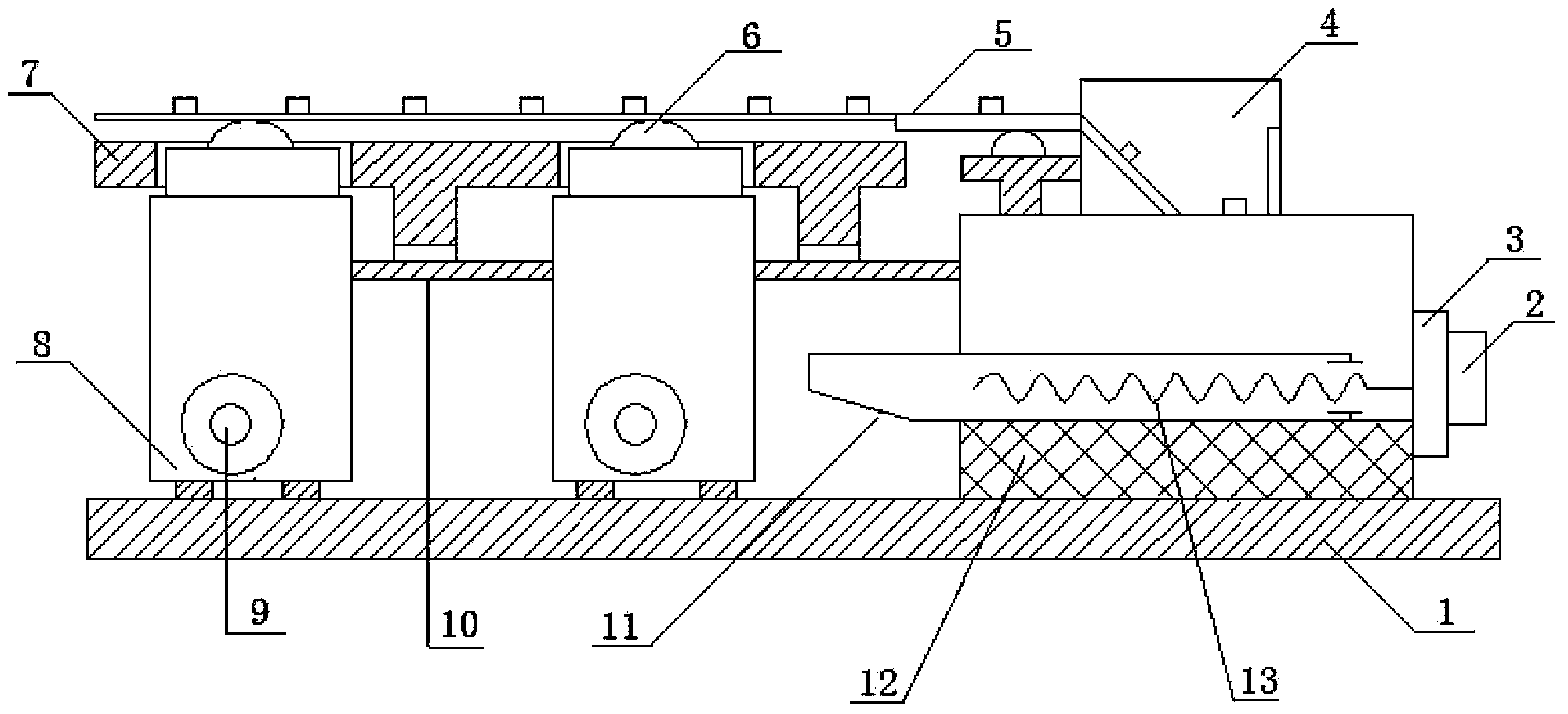

[0009] The workpiece feeding mechanism has a base (1), and a fixed plate (8), a roller (9) and a pressing plate seat (12) are respectively installed on the base (1), and a progressive motor (2) is installed on the pressing plate seat (12). With the reducer (3), a screw mandrel (13) is connected to the reducer (3), and a pressing plate (11) is installed on the screw mandrel (13), and a discharge mechanism (4) is arranged on the plane of the pressing plate (11). ), a pallet (10) is installed on the discharge mechanism (4), a support seat (6) is provided on the pallet (10), a roller plate (5) is installed on the support seat (6), and a roller plate (5) Workbench (7) is connected on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com