Design Method of Center of Gravity Dispersion Moment Balance Ball Mill

A design method and ball mill technology, applied in grain processing, etc., can solve the problems of high energy consumption of gravity resistance torque, friction resistance torque, etc., and achieve the effects of good strength structure, reduced energy consumption, and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A. Change the single cylinder of the ball mill to a multi-cylinder structure to eliminate the resistance moment formed by the gravity of the processed material;

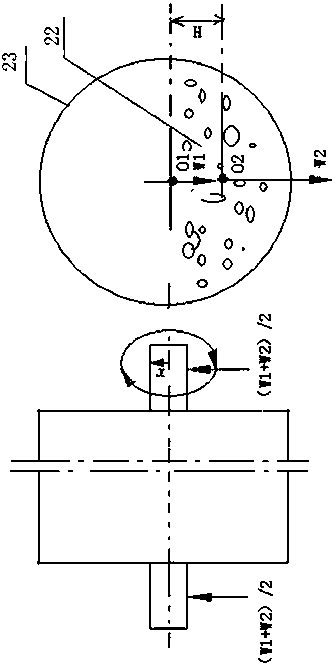

[0046] In this embodiment, the single cylinder of the ball mill is changed to three cylinders, and the force state during operation will change, such as figure 2 As shown, the single tube is changed to three small tubes fixed equilaterally, and the working state is the same as that of the single tube, and the central axis is also used to rotate. If the total weight of the ball mill barrel is W1, the total weight of the processed material is W2, and the weight of the material in each barrel is W2 / 3, the resistance torque that causes the ball mill to rotate at this time is mainly formed by the friction force generated by the total gravity and the shaft diameter. The resistance torque (W1+W2) μr; and the resistance torque generated by the weight of the materials in the three cylinders, at this time, because the mate...

Embodiment 2

[0049] Example 2 Energy-saving structure design of ball mill

[0050] The energy-saving structure of the ball mill has the following sections:

[0051] Energy-saving structure design scheme of cement ball mill, cement dryer, ceramic ball mill and other equipment

[0052] Intermittent ball mills used in ceramic factories are mostly center-rotating, and their working processes include three processes: feeding, rotary grinding, and discharging; ball mills and dryers used in cement factories are mostly supported by rollers, driven by peripherals, and barrels. It is in a rolling and rotating way with the idler. The barrel structure of this equipment can be designed into the following sections. The multi-tube structure has the following sections:

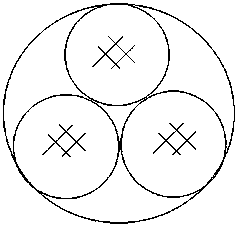

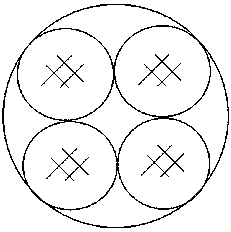

[0053] 1) Combine multiple (three or more) small diameter cylinders

[0054] see Figure 7-9 , Replace the single-tube structure with three or more small cylinders of the same size. The principle of the center of gravity of each cylinder can be ...

Embodiment 3

[0061] When the intermittent ceramic ball mill adopts a torque balance structure, a drive device for loading and unloading should be added.

[0062] For the ball mill, when the center of gravity distributed torque balance structure is adopted, the working driving mode of the cylinder body is the same as the working driving mode of the traditional single cylinder, but for the intermittent ceramic ball mill, a set of upper and lower This is because the balanced ball mill has a multi-space structure. Each space must have an upper and lower material opening. Therefore, during the loading and unloading process, each upper and lower material opening should be positioned and fixed. The inlet and outlet of the The opening and closing of the inlet and outlet and the feeding process are carried out at the top, and the discharging process is carried out at the bottom to prevent the rotation of the cylinder due to the deviation of the center of gravity during the loading and unloading process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com