Permeation grouting integrated rod suitable for shield tunnel, and construction method

A technology of shield tunneling and integrated rods, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as soil instability and complex construction, and achieve the dissipation of super-gap water pressure. It has a wide range of applications and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

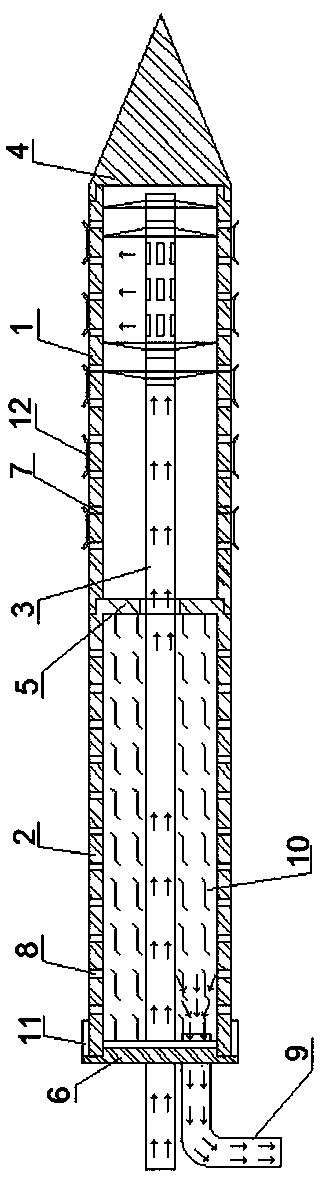

[0029] Such as figure 1 As shown, a permeation grouting integrated rod suitable for shield tunneling includes grouting rod 1, permeation rod 2 and grouting pipe 3. Both grouting rod 1 and permeation rod 2 are tubular structures, and the grouting rod 1 A plug 4 is fixed at the head end, and the tail end of the grouting rod 1 is sealed and fixedly connected with the head end of the permeation rod 2 . The first end of the penetration rod 2 is fixed with a partition 5, the partition 5 divides the grouting rod 1 and the penetration rod 2 into two chambers, and the tail end of the penetration rod 2 is fixed with an end plate 6, and the end plate 6 divides the penetration rod 2 into two chambers. end seal. Grouting holes 7 are evenly distributed on the surrounding wall of the grouting rod 1, and water seepage holes 8 are evenly distributed on the peripheral wall of the permeatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com