Tool for fabricated concrete wall lifting adjustment, fabricated wall and construction method

A concrete wall, prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of water leakage, easy damage, incomplete structure, etc., and achieve the effect of convenient operation method, safe hoisting, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 of the present invention provides a tooling for hoisting and adjusting a fabricated concrete wall, including a structural member (a structural member with an L-shaped cross section, that is, an angle steel structural member is preferably used) and bolts;

[0054] The structural member includes a first substrate and a second substrate connected to the first substrate; perforations are provided on the surface of the first substrate of the structural member, and prying holes are provided on the surface of the second substrate of the structural member The rod is inserted into the hole; and the through hole is used to pass through the bolt, and the bolt is used to fix and connect the structural member to the prefabricated component.

[0055] It should be noted that angle steel, commonly known as angle iron, is a long strip-shaped structural plate whose two sides are perpendicular to each other and form an angle. Apparently, the prefabricated concrete wall hoisti...

Embodiment 2

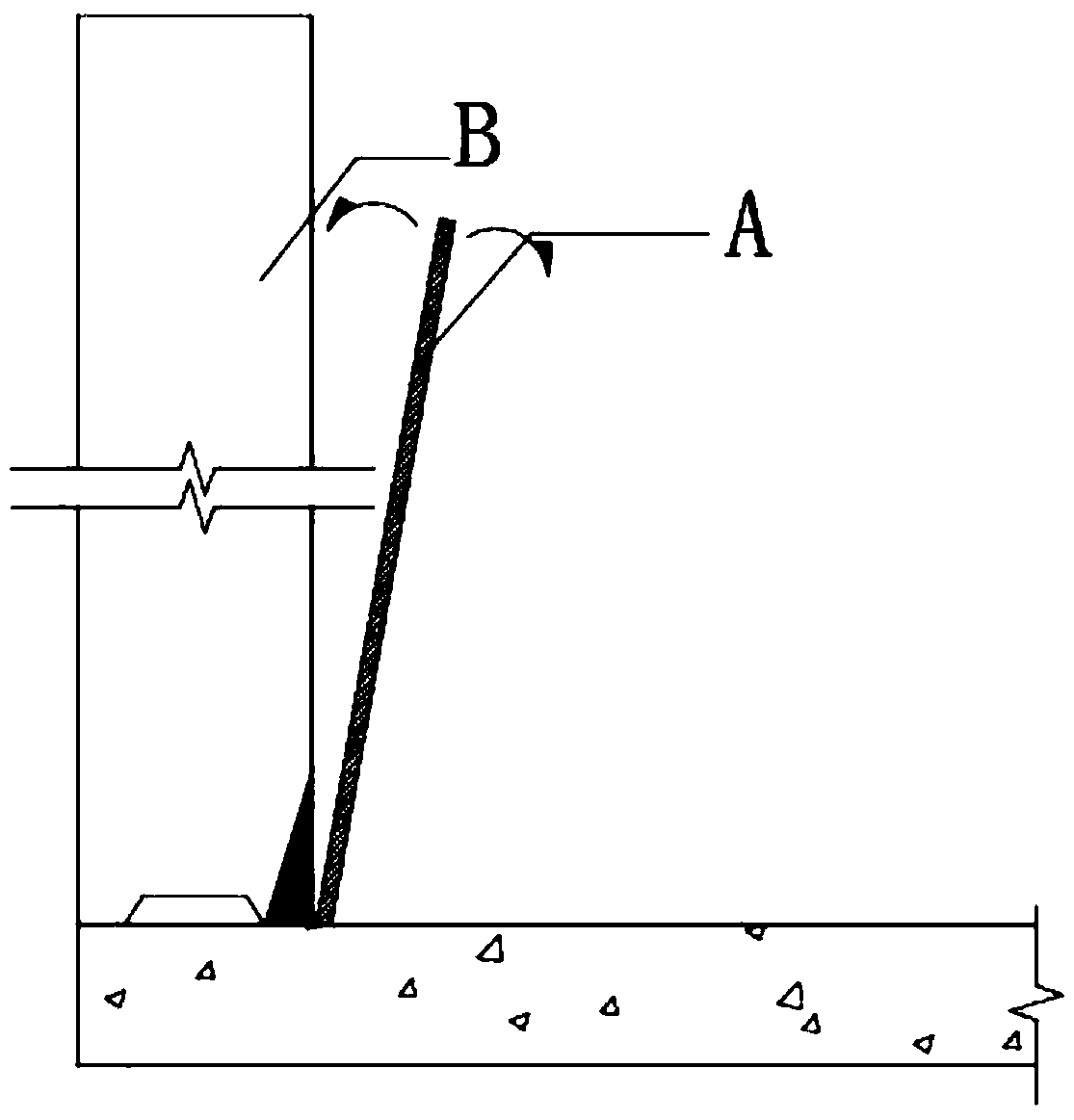

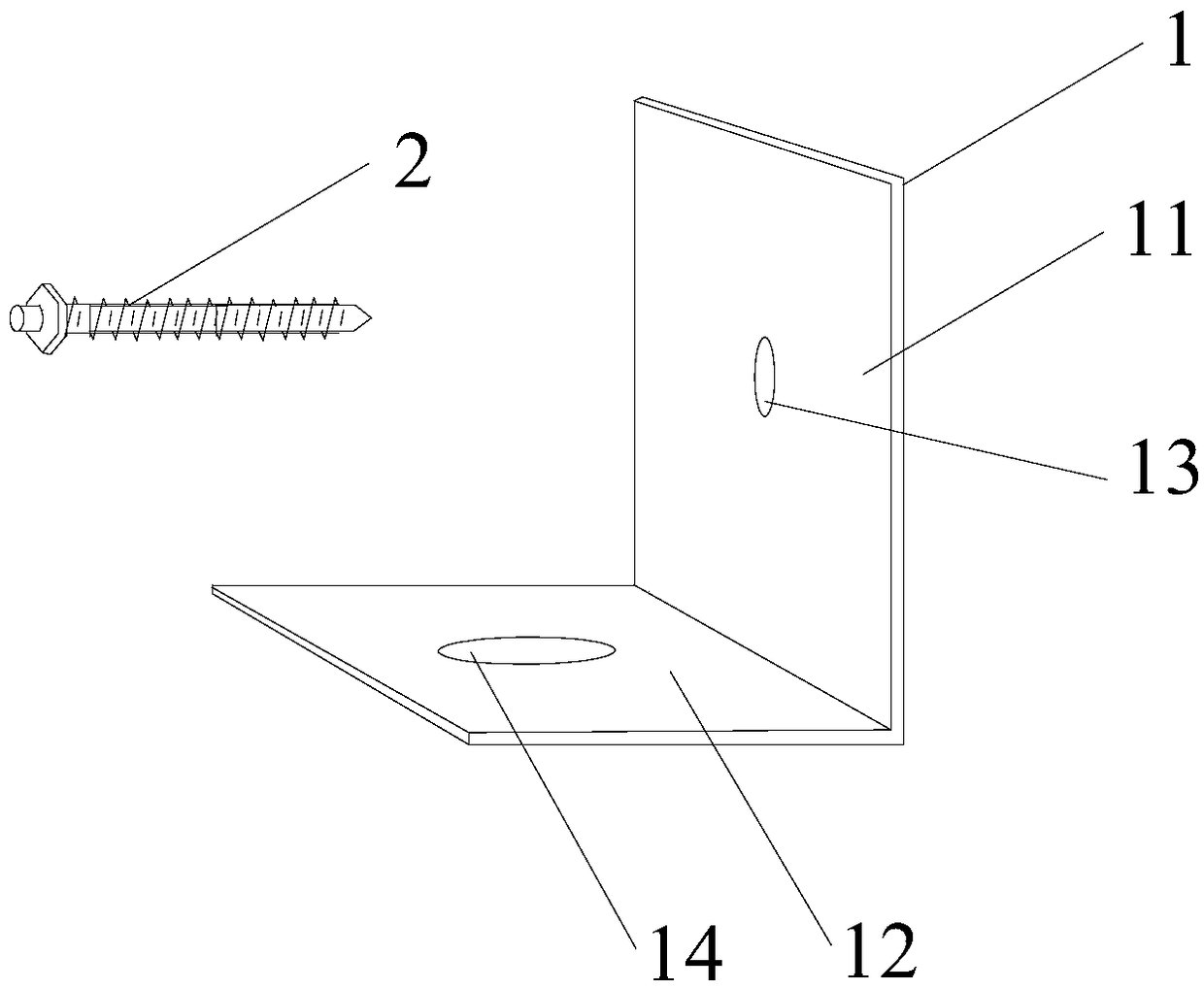

[0058] see figure 2 , image 3 , Embodiment 2 of the present invention provides a fabricated concrete wall hoisting and adjusting tooling, including a structural member 1 (ie angle steel) and bolts 2; the structural member includes a first base plate 11 and a first base plate connected to the first base plate Two substrates 12; the first substrate 11 of the structural member is provided with a perforation 13, and the second substrate 12 of the structural member is provided with a crowbar insertion hole 14 (the crowbar insertion hole 14 is convenient for prying) and the perforation 13 is used to pass through the bolt, and the bolt 2 is used to fix the structural member 1 in the reserved bolt hole of the prefabricated component B. Figure 4 It is a schematic diagram of the actual operation effect of the tooling for hoisting and adjusting the fabricated concrete wall in the second embodiment.

[0059] It should be noted that Embodiment 2 of the present invention provides a too...

Embodiment 3

[0065] Such as Figure 5 as well as Image 6 As shown, Embodiment 3 of the present invention provides a kind of tooling for the hoisting and adjustment of a prefabricated concrete wall, including a structural member 1 (ie angle steel) and a bolt 2; the structural member includes a first base plate 11 and is connected to the first base plate The second substrate 12 of the structure; the first substrate 11 of the structural member is provided with a perforation 13, and the second substrate 12 of the structural member is provided with a crowbar insertion hole 14 (the crowbar insertion hole 14 is to facilitate crowbar penetration); and the perforation 13 is used to pass through the bolt, and the bolt 2 is used to fix the structural member 1 in the reserved bolt hole of the prefabricated component B.

[0066] The fabricated concrete wall hoisting and adjusting tooling designed in Embodiment 3 of the present invention has the same structure as Embodiment 1, and on the basis of Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com