Pregnant solution impurity removing method for indirect gold mine heap leaching process

A technology of precious liquid and gold mine, applied in the direction of improving process efficiency, etc., can solve problems such as high cost, low sodium sulfide precipitation rate, complicated process, etc., and achieve the effect of wide pH range, good precipitation effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

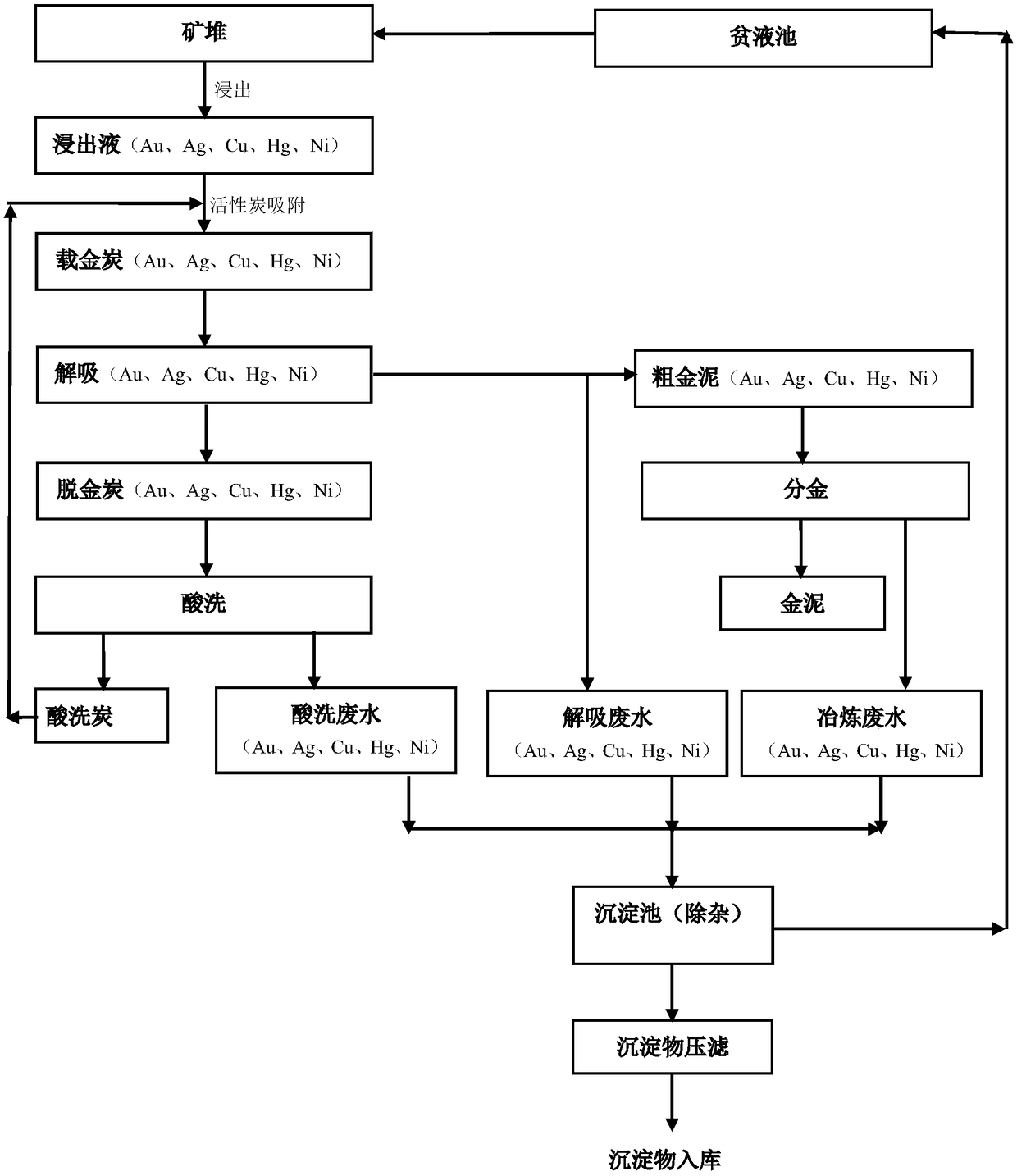

[0021] A kind of impurity-removing method of precious liquid of indirect gold ore heap leaching process: add activated carbon adsorbent in the precious liquid of gold ore heap leaching, after about 20 days, the active carbon (containing gold Au, silver Ag, copper Cu, mercury Hg containing gold Au, silver Ag, copper Cu, mercury Hg , Nickel Ni, etc.) are taken out and desorbed to obtain desorption wastewater and activated carbon after desorption, the activated carbon after desorption is carried out pickling treatment, the activated carbon after the treatment can be reused, the acid wastewater obtained by the pickling treatment, and the desorption wastewater, And the smelting wastewater generated during the gold mud smelting process is put into the sedimentation tank, and the impurity removal agent is used for impurity removal treatment. The treated water can be returned to production for recycling, and the sediment is press-filtered and put into storage.

Embodiment 2

[0023] A method for removing impurities in expensive liquid of an indirect gold ore heap leaching process, adding activated carbon into the expensive liquid for gold ore heap leaching, and taking out the saturated activated carbon after 20 days for desorption to obtain desorption waste water and activated carbon after desorption. The activated carbon after desorption is pickled, and the acidic wastewater obtained by the pickling treatment, as well as the desorption wastewater, and the smelting wastewater generated when the gold mud is smelted are put into the sedimentation tank, and the high-efficiency impurity remover is used for the impurity removal treatment, and the sediment is cleaned. Press filtration, storage;

[0024] The high-efficiency impurity remover is a mixture of lime sulfur and polysodium chloride; the lime sulfur is boiled from a mixture of 1 part of lime, 2 parts of sulfur powder and 10 parts of water; The mixture of mixture and polysodium chloride, the weigh...

Embodiment 3

[0026] A kind of impurity removal method of precious liquid of indirect gold ore heap leaching process, activated carbon is added in the precious liquid of gold ore heap leaching, after 21 days, the activated carbon saturated with adsorption is taken out, desorbed, and desorption waste water and desorbed activated carbon are obtained, and The activated carbon after desorption is pickled, and the acidic wastewater obtained by the pickling treatment, as well as the desorption wastewater, and the smelting wastewater generated when the gold mud is smelted are put into the sedimentation tank, and the high-efficiency impurity remover is used for the impurity removal treatment, and the sediment is cleaned. Press filtration, storage;

[0027] The high-efficiency impurity remover is a mixture of lime sulfur and polysodium chloride; the lime sulfur is boiled from a mixture of 1 part of lime, 2 parts of sulfur powder and 10 parts of water; The mixture of mixture and polysodium chloride, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com